Oil and water phase material gas delivery apparatus and technology thereof

A technology for conveying materials and water phase, applied in explosives processing equipment, explosives, attack equipment and other directions, can solve the problems of high freezing point of oil phase solution, high crystallization point of water phase solution, difficult to solve pipeline residual liquid, etc., and achieves a simple structure. , Good safety and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

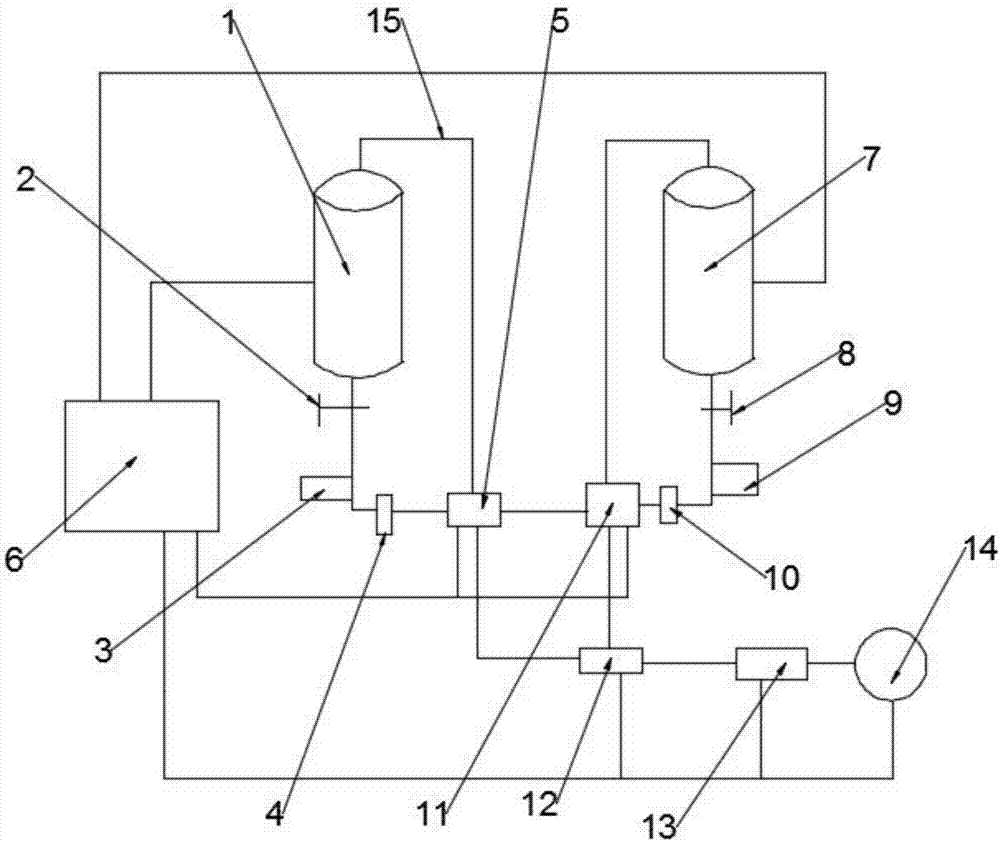

[0016] see figure 1 , an oil-water phase gas conveying material device, comprising a water-phase sealed reaction kettle 1, an oil-phase sealed reaction kettle 7, an air compressor, an oil-phase intermediate tank 10, a water-phase intermediate tank 4, an oil-phase storage tank 11, and a water-phase storage tank Tank 5, static emulsifier 12, static sensitization disperser 13, filling equipment 14 and control terminal 6, the air compressor includes water phase air compressor 3 and oil phase air compressor 9, water phase sealed reaction kettle 1 The inner barrel of the oil-phase sealed reactor 7 is made of a pressure-resistant material, and the feed port of the water-phase sealed reactor 1 and the oil-phase sealed reactor 7 is equipped with a pneumatic gate valve, and the lower end of the water-phase sealed reactor 1 is equipped with a The water phase ch

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap