Oil-free double-rotor heat dissipation type air compressor

An air compressor, double rotor technology, applied in rotary piston/swing piston pump components, mechanical equipment, machines/engines, etc., can solve the problem of increasing compressor power consumption, poor heat dissipation, and reducing work efficiency, etc. problems, to achieve the effect of reducing power consumption, improving service life and using safety, and having strong dust-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

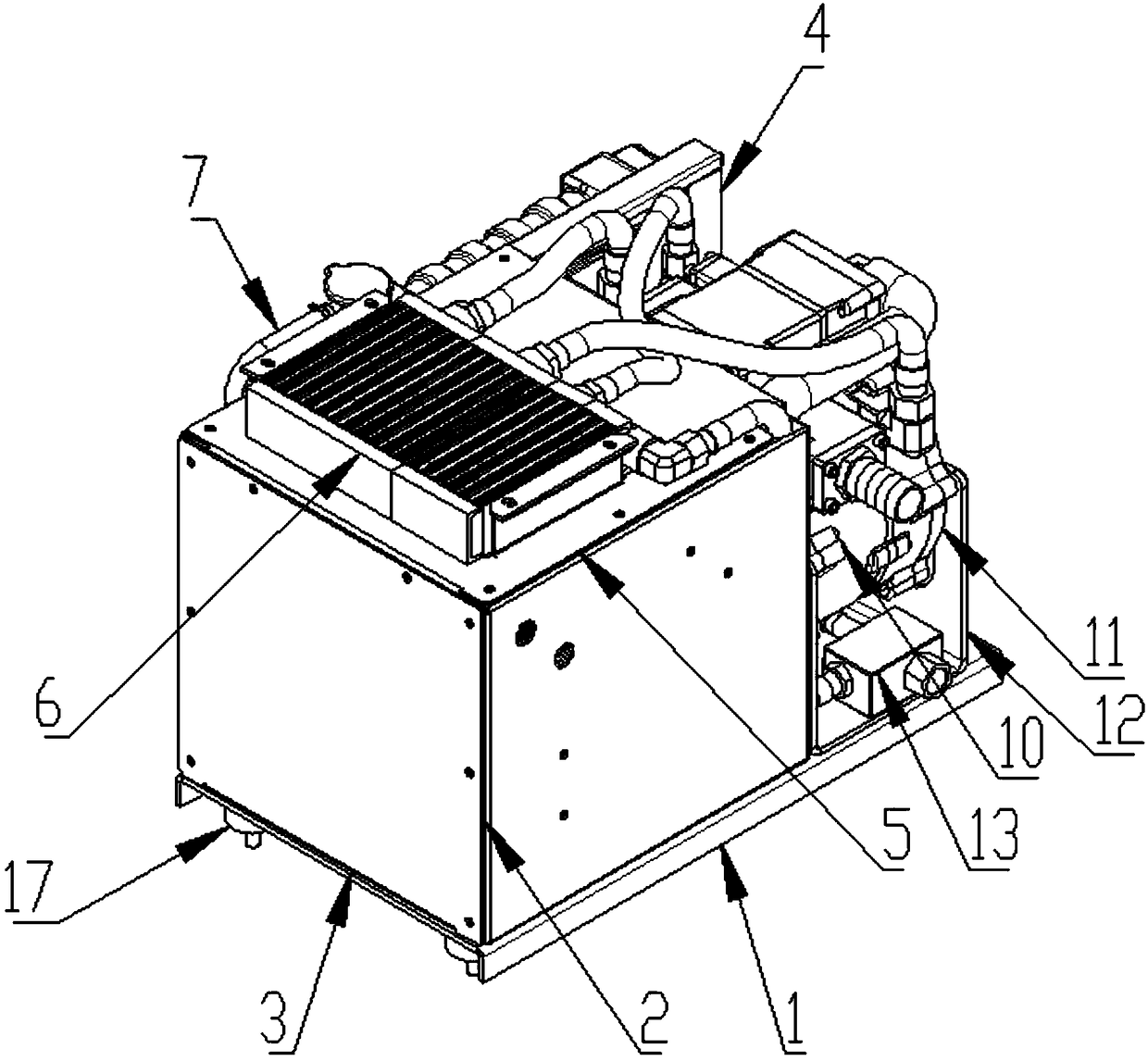

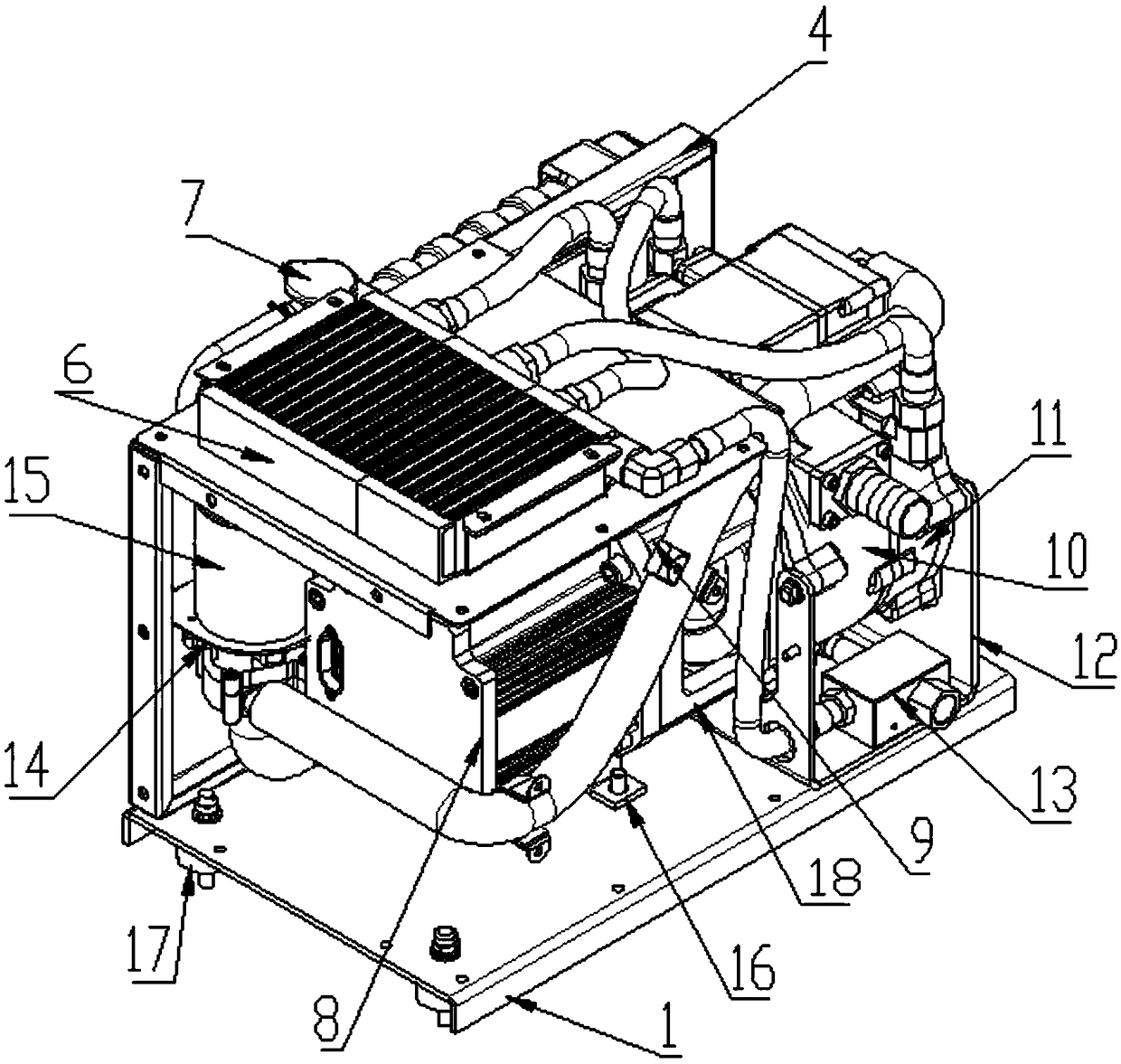

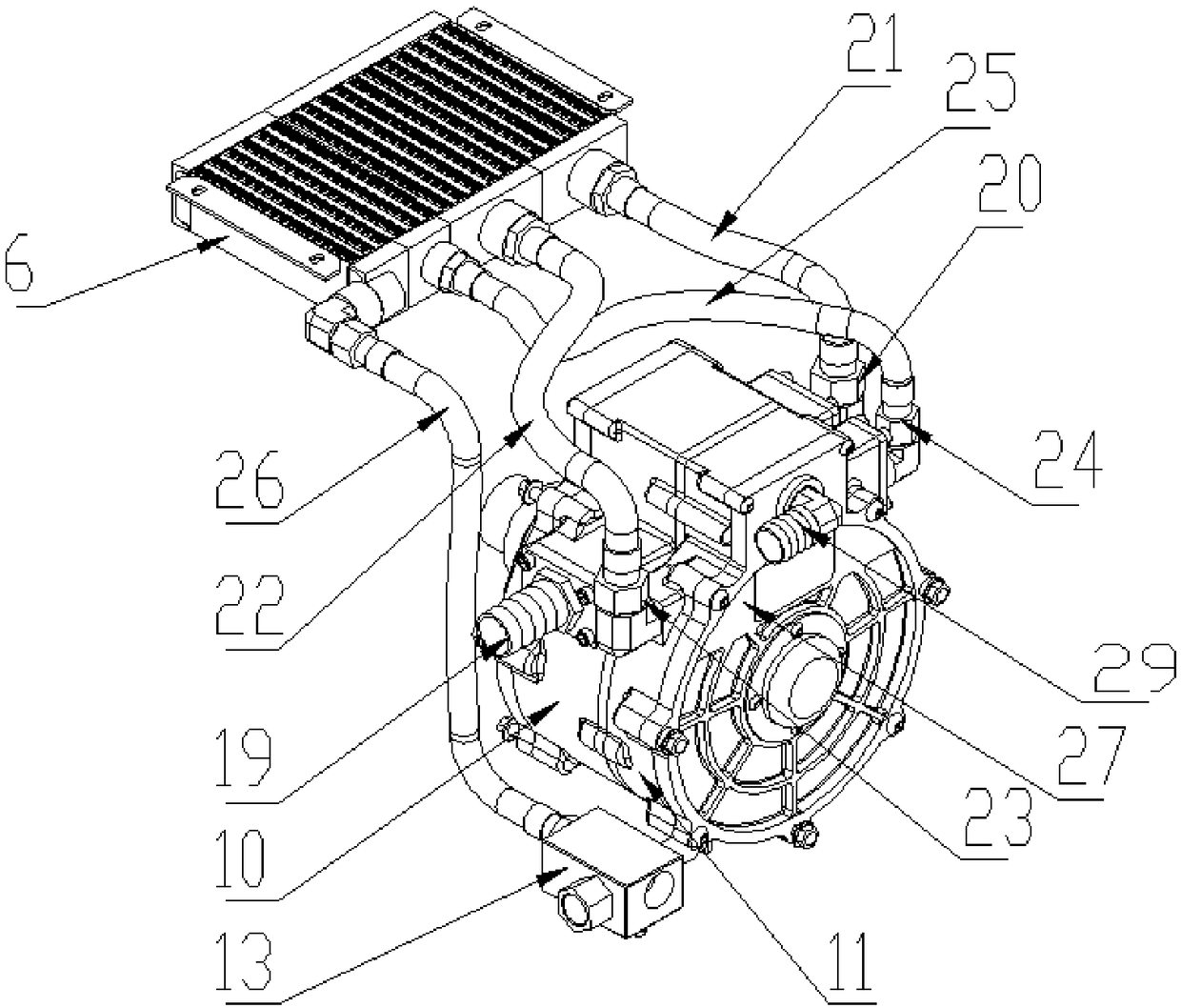

[0020] Embodiment 1, see Figure 1-Figure 5 , an oil-free dual-rotor cooling air compressor, including a bottom support 1, a side support 2, a rear support 3, a heat dissipation support 4, a top support 5, an air cooler 6, a water radiator 7, a motor 8, and a coupling 9. Primary cylinder 10, primary water hole 101, secondary cylinder 11, secondary water hole 111, machine head support 12, exhaust port 13, water pump support 14, water pump 15, motor support 16, direct-connected motor Seat 18, primary air inlet 19, primary air outlet 20, primary air intake pipe 21, primary air outlet pipe 22, secondary air outlet 23, secondary air outlet 24, secondary air intake pipe 25, secondary air outlet pipe 26. Front water cover 27, primary water inlet pipe 28, primary water inlet 29, rear water cover 30, primary water outlet 31, primary water outlet pipe 32, secondary water outlet pipe 33, fan 34, rear water cover 35, Three-level water hole 351; wherein: the bottom of side support 2, rear su

Embodiment 2

[0021] Example 2, see figure 1 , an oil-free dual-rotor heat dissipation air compressor, wherein: the air cooler 6 is provided with two cooling chambers, and simultaneously cools the compressed air of the primary cylinder 10 and the secondary cylinder 11. All the other are with embodiment 1.

Embodiment 3

[0022] Example 3, see figure 1 , an oil-free dual-rotor heat-dissipating air compressor, wherein: the bottom of the bottom bracket 1 is fixed with a shock absorber 17 to reduce vibration and prevent noise. All the other are with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap