Well mouth eccentric pressurizing sleeve oil recycling mobile device of production well

A technology for mobile devices and oil production wells, which is applied in wellbore/well parts, production fluid, earthwork drilling and production, etc., to achieve significant economic benefits, convenient and quick oil collection, and avoid the loss of crude oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

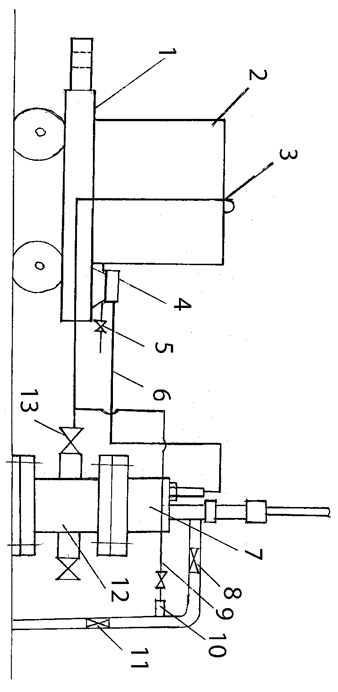

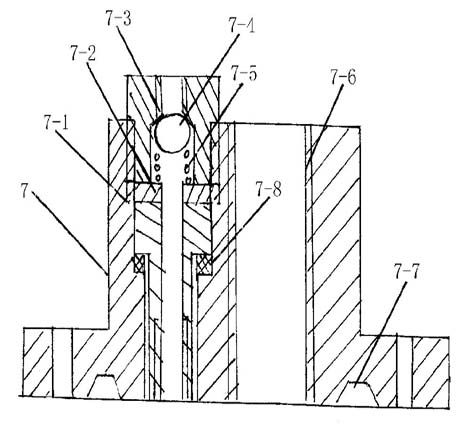

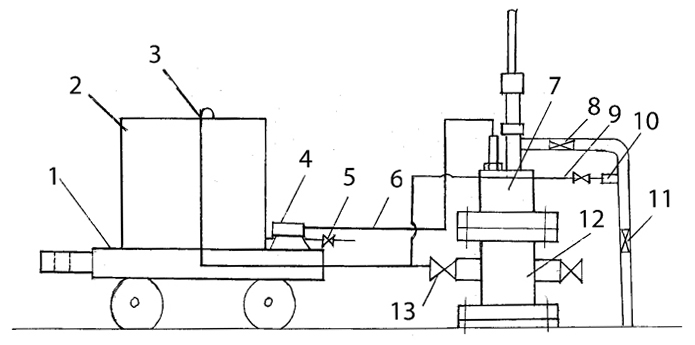

[0020] The invention is mainly composed of trailer 1, oil collection tank 2, oil collection pipe 3, air compressor 4, oil discharge valve 5, air delivery pipe 6, eccentric suspension mechanism 7, oil return pipe 9 and check valve 10, and is characterized in that The production tee flange on the upper part of the tree is designed to be suspended by the air intake pipe suspension hole, the air intake pipe suspension head in the middle of the air intake pipe suspension hole, the upper middle gasket, the upper air pipe joint with check valve and the air intake pipe. On one side of the hole, the eccentric suspension mechanism is composed of a connection hole that is integrated with the production tee connection and the oil pipe suspension; the air intake pipe suspension head is connected with an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap