Liquid pump type air compressor

A technology of air compressors and liquid pumps, applied in the field of gas compressors, which can solve the problems of easy overheating and damage of compressors, high cost of manufacturing and use, and high cost of silence, and achieve the effects of high compression efficiency, high airtightness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

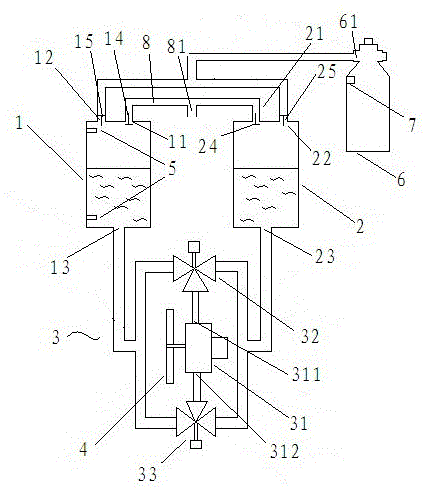

[0024] Such as figure 1 As shown, the liquid pump air compressor provided in this embodiment mainly includes a first compressor tank 1, a second compressor tank 2 and a driving device 3. The first compressed air tank 1 and the second compressed air tank 2 are respectively connected to the driving device 3.

[0025] Specifically, the upper end of the first compressed air tank 1 has a first air inlet 11 and a first air outlet 12, and the lower end has a first liquid infusion port 13. A one-way valve 14 is provided on the first air inlet 11, and a one-way valve 15 is provided on the first air outlet 12, that is, the first air inlet 11 can only take in air but not air out, and the first air outlet 12 can only let out air No air intake. There is no valve on the first infusion port 13, so that the first infusion port 13 can both enter and exit water.

[0026] The upper end of the second compressor tank 2 has a second air inlet 21 and a second air outlet 22, and the lower end has a second

Embodiment 2

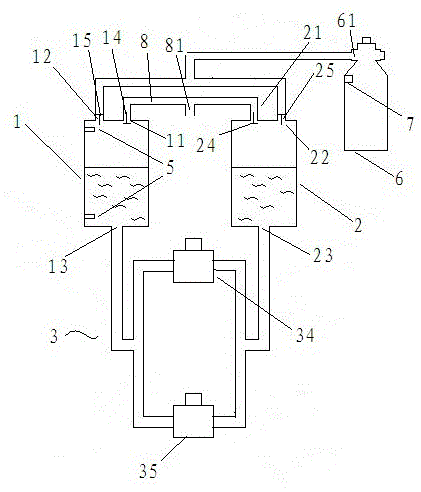

[0037] The difference between the liquid pump air compressor provided in this embodiment and the first embodiment is the structure of the driving device 3.

[0038] Such as figure 2 As shown, the driving device 3 includes a first water pump 34 and a second water pump 35, the first water pump 34 and the second water pump 35 are arranged side by side, the first infusion port 13 of the first compressed air tank 1 and the second infusion of the second compressed air tank 2 The ports 23 are respectively connected to the first water pump 34 and the second water pump 35 through a Y-shaped three-way water pipe. The first water pump 34 is used to squeeze the water in the first compressed air tank 1 into the second compressed air tank 2, and the second water pump 35 It is used to squeeze the water in the second compressor tank 2 into the first compressor tank 2, or the first water pump 34 and the second water pump 35 are driven in opposite directions.

[0039] The function of the driving devi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap