Sealing multiwell plates

a multi-well plate and sealing technology, applied in the field of sealing multi-well plates, can solve the problems of inability to easily sterilize the roll of heat sealing material, unsatisfactory for some uses such as diagnostics or forensics, and the machine is both complex and costly. , to achieve the effect of avoiding contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

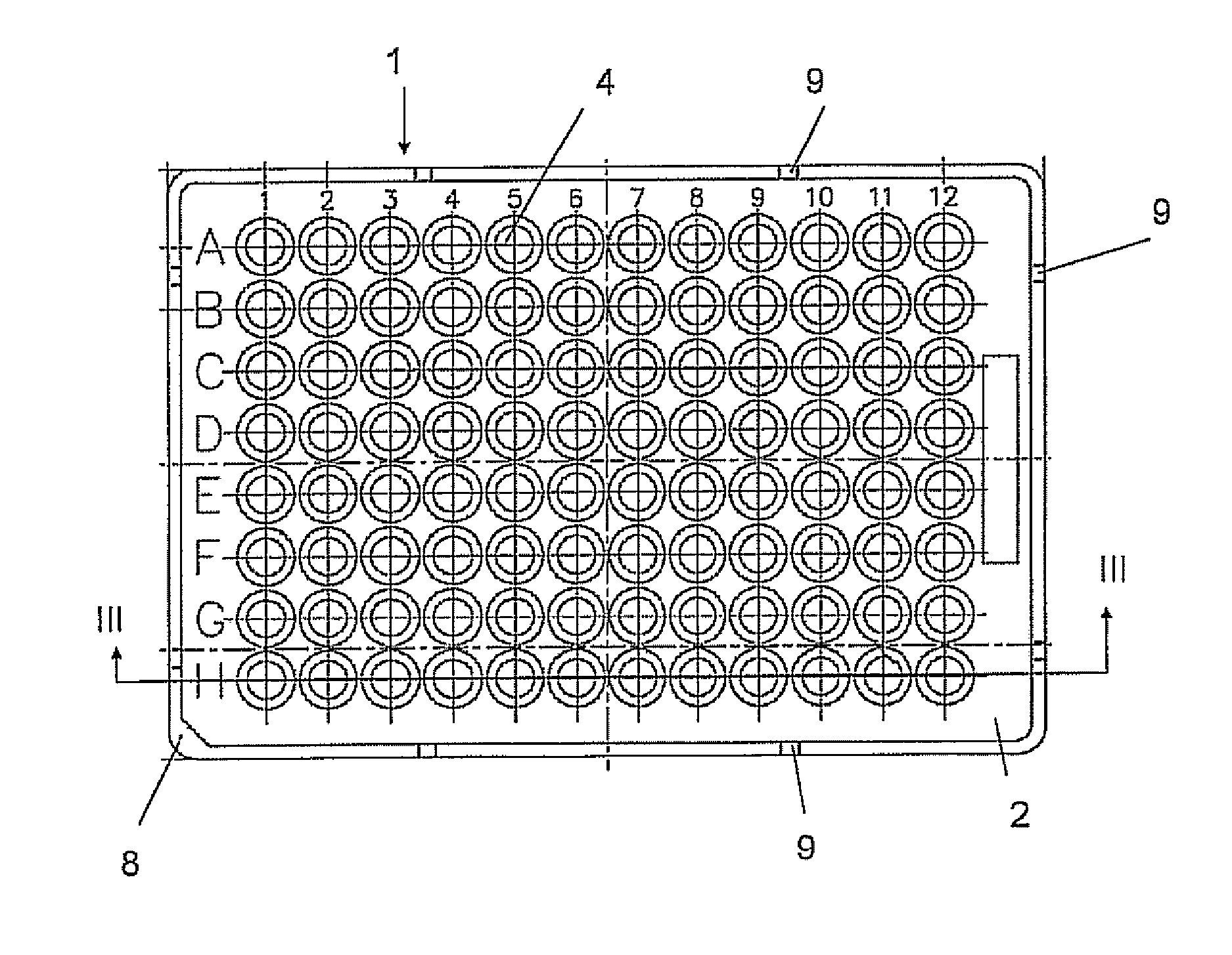

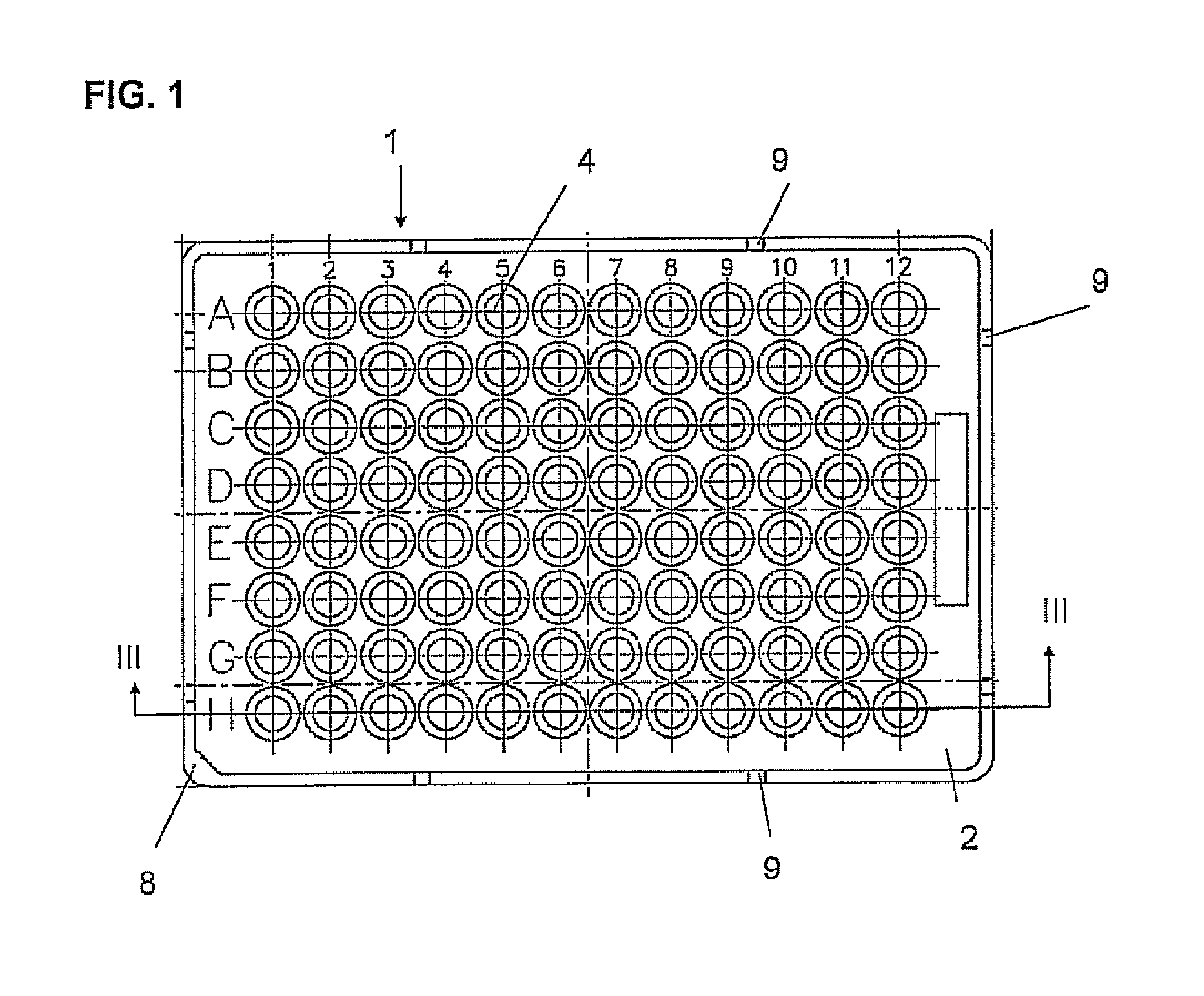

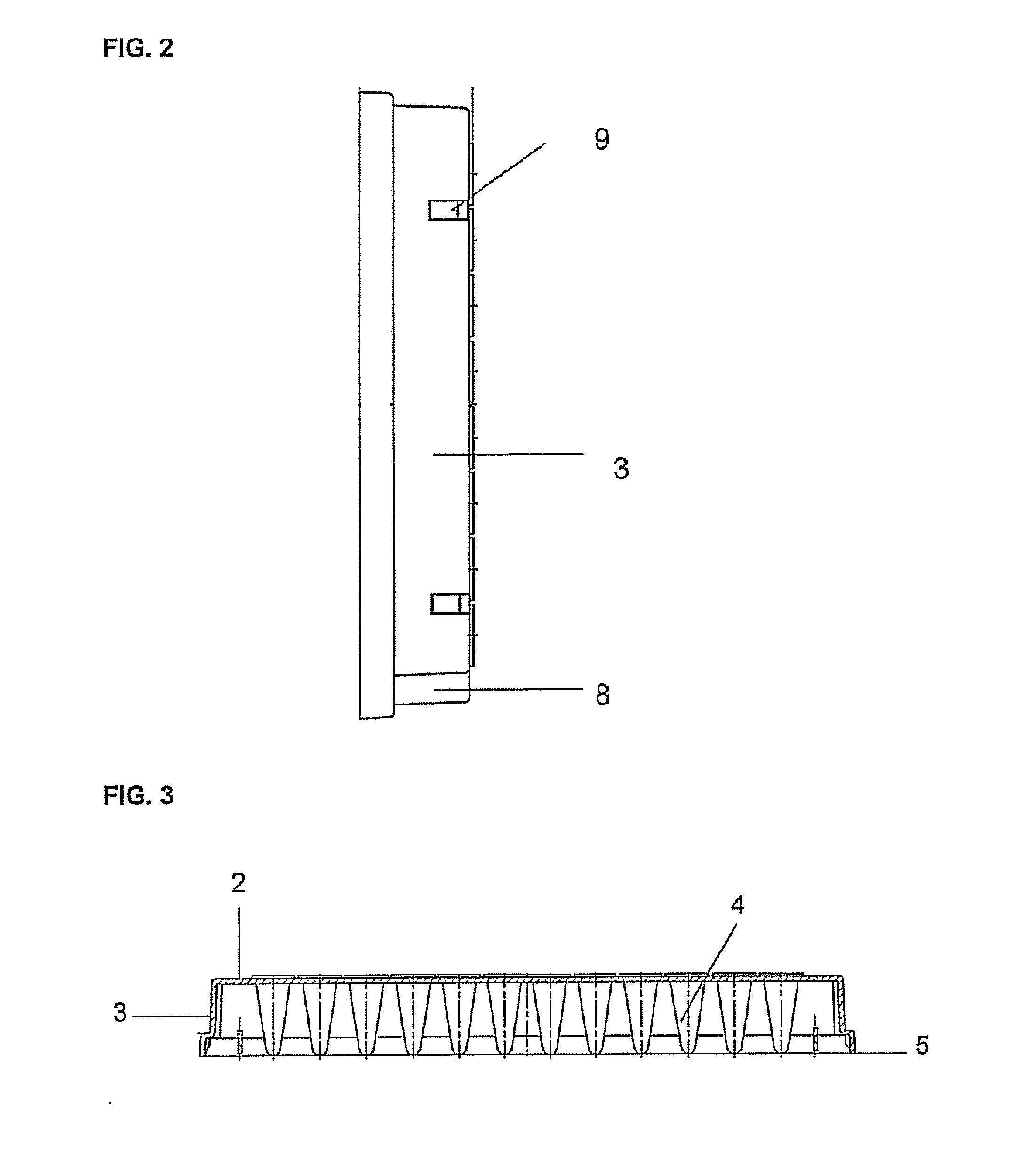

[0017]The multiwell plate 1, shown in FIGS. 1 to 4, comprises a plate 2 with an integral skirt 3, the plate mounting an array of individual thin walled wells 4. Lower edge 5 of skirt 3 is formed with an outwardly displaced rim 6, enabling the plates to be stacked one upon the other with the displaced rim fitting over the edge between plate 2 and skirt 3 of an underlying multiwell plate in the stack. The individual wells 4 are mounted in openings in the plate 2 with rims 7 extending above the surface of the plate 2. The plate has a chamfered corner region 8 and cut-outs 9 for indexing purposes. The design of multiwell plates is subject to a number of Standards, such as the SBS Standard, in order for multiwell plates from different manufacturers to be compatible with automatic plate handling apparatus, for example for performing the PCR (polymerase chain reaction) process; but persons skilled in this art will know that a number of variations are commonly encountered, including semi-skirt

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap