Cleanable articles and methods for making and using same

A technique for cleaning articles, front surfaces, used in reusable writing boards, chemical instruments and methods, layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0129] The invention is further explained below by means of illustrative, non-limiting examples.

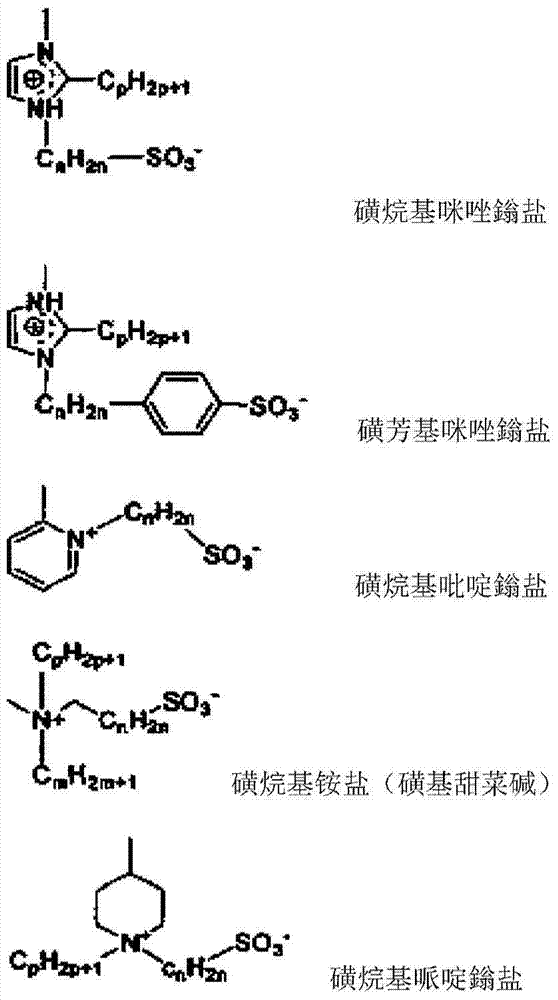

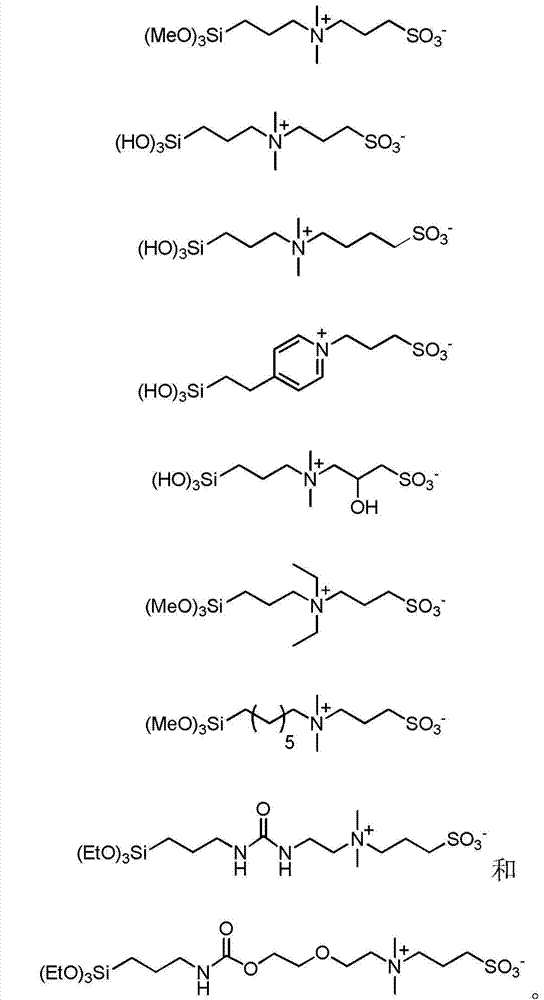

[0130] Substances utilized in the examples include:

[0131]

[0132] The following test method was used to evaluate the removal of permanent marker writing.

[0133] Use SHARPIE on the test surface TM Write with black permanent marker. After 24 hours at room temperature, water was applied to the surface. The writing on the surface is then wiped with a damp paper towel. Continue scraping until the writing is removed, or there is no change in the amount of marking left on the board. Record whether writing is removed by wet wipes. For permanent markers that are difficult to remove with water alone, spray some WINDEX on the writing TM glass cleaner, then wipe with a paper towel to remove.

example 1

[0135] The outer coating of Example 1 was formed from a composition by adding 3-(N,N-dimethylaminopropyl)trimethoxysilane (49.7 g, 239 mmol) to a screw cap jar , then prepared by adding deionized (DI) water (82.2 g) and 1,4-butane sultone (32.6 g, 239 mmol). The combined reaction mixture was heated to 75°C and mixed for a period of 14 hours. The resulting reaction mixture was diluted with water to 2% by weight to obtain a final coating composition, which was then applied to the front surface of the body member.

[0136] In Example 2, the overcoat was formed from a composition prepared as 2% by weight of [LITHISIL TM 25 Lithium silicate: Example 1 preparation composition (23:77 w / w)] in aqueous solution.

[0137] 100% SHARPIE after 10 uses TM The black permanent marker remains easily removable. After seven uses, the marker lined the glossy sample, but the optically rough structured surface caused by rolling was not lined with the marker. Thus, durability is improved by mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap