Fire rated radius wall structure

a radius wall and structure technology, applied in the direction of walls, heat proofing, forms/shuttering/falseworks, etc., can solve the problems of not being able to meet modern fire codes, difficult and cumbersome to attach wallboards to studs, and few options for building such curved walls. , to achieve the effect of convenient construction/installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

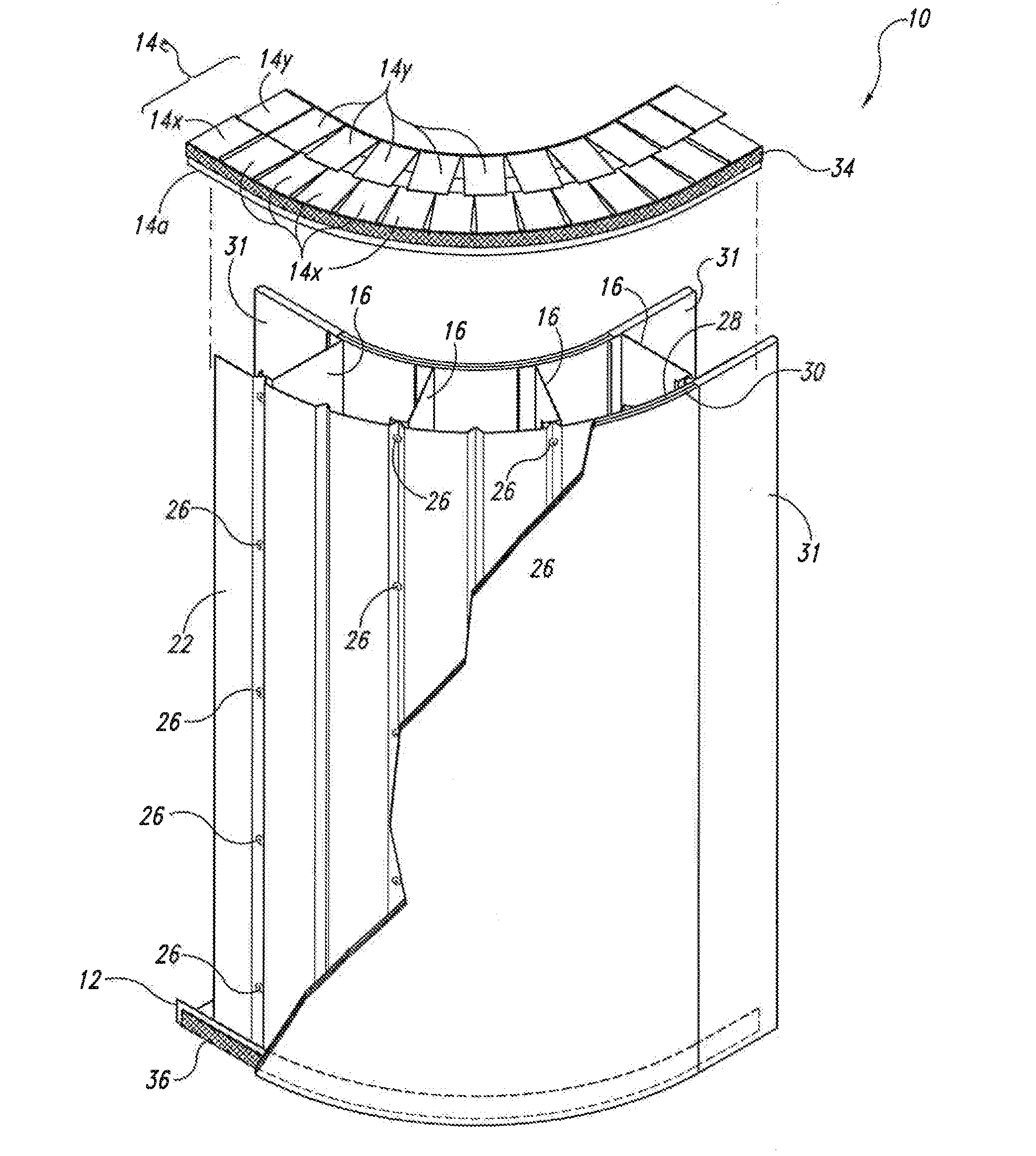

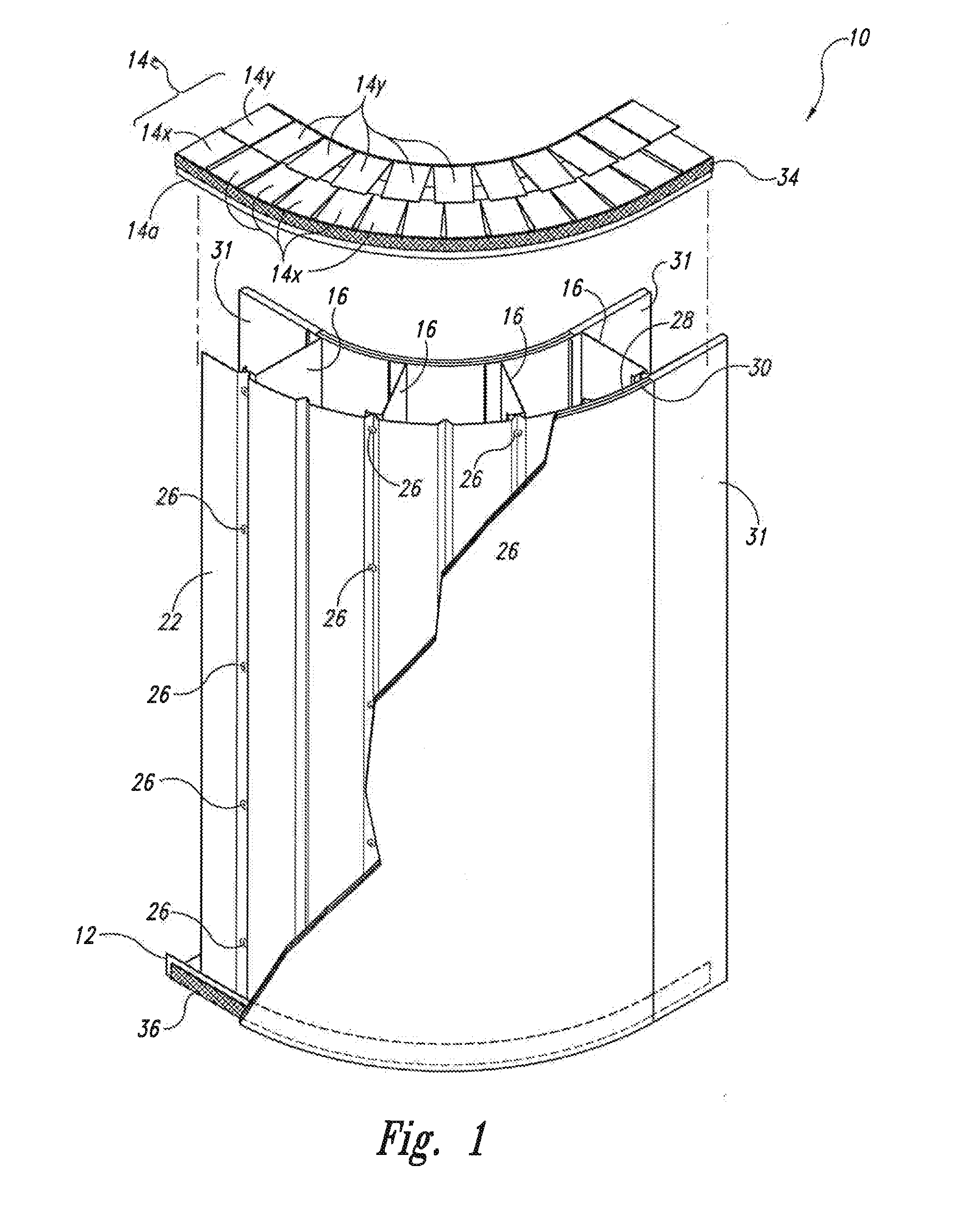

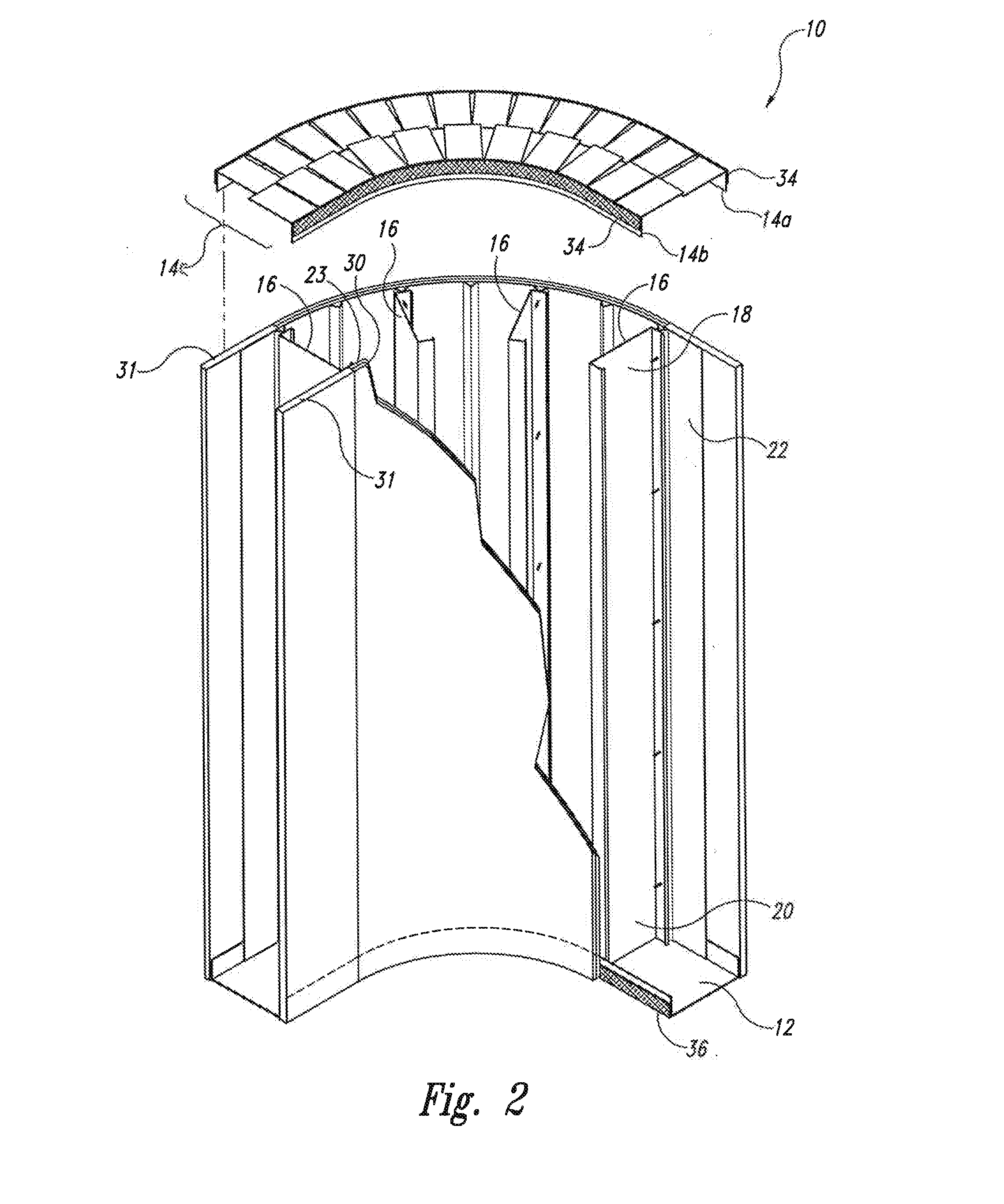

[0019]Referring now to the drawings wherein like reference numerals are used to designate like features and, more particularly, to FIGS. 1-10, the present invention in one embodiment is directed to a curved (radius) wall structure 10 that is easy to construct / install on-site within a building (not shown) and that may optionally be fire-rated to comply with applicable fire codes. As shown in FIGS. 1 and 2, the curved wall structure 10 is an assembly that comprises a curved footer track 12; a curved header track 14 confronting and vertically spaced apart from the curved footer track 12; a plurality of studs 16 having upper and lower end portions 18, 20, (wherein the studs 16 are vertically positioned between the spaced apart and confronting header and footer tracks 12, 14 such that the lower end portions 20 are received into the footer track 12 and the upper end portions 18 are received into the curved header track 14); and a corrugated curved wall panel 22 having a plurality of vertic

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap