Aerial optical cable

An overhead optical cable and optical fiber technology, which is used in optical fiber/cable installation, stamps, instruments, etc., can solve the problems of inconvenient maintenance, maintenance, and difficult maintenance of optical fibers and cables, and achieves low maintenance cost, high finished product qualification rate, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

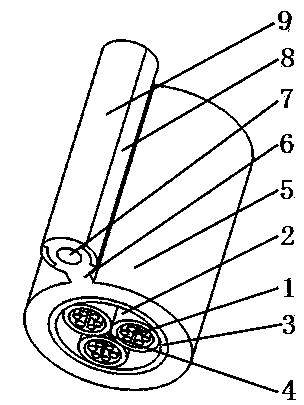

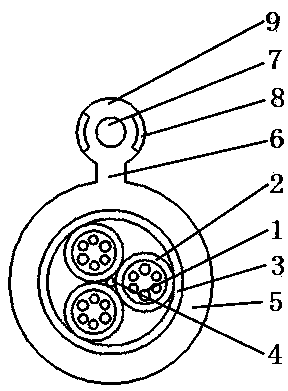

[0026] please see figure 1 and figure 2 , an overhead optical cable, which includes a central strength member 4, three loose tubes 2 distributed around the outer edge of the central strength member, a moisture barrier layer 3 coated outside the loose tube, and an extrusion coating outside the moisture barrier layer The outer sheath 5 has six optical fibers 1 in the loose tube, which is characterized in that: outside the outer sheath, there is also a suspender layer 9, inside the suspender layer there is a suspension reinforcement 7, and the suspender layer and the outer sheath pass through the connecting rib 6 connected, the suspender layer on both sides of the suspension reinforcement has identification strips 8 embedded in the suspender layer and having different colors from the suspender layer, the suspender layer and the outer sheath are distributed in parallel in space, and the suspender layer, the outer sheath, The materials of the connecting ribs are the same, and the su

Embodiment 2

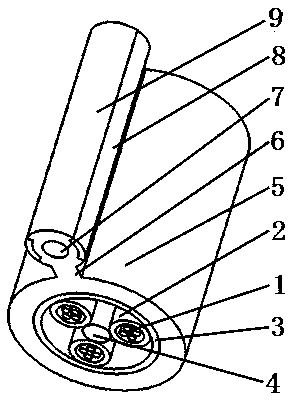

[0028] please see image 3 and Figure 4 , and refer to figure 1 and figure 2 , an aerial optical cable, which is basically the same as the implementation example 1, the difference is that there are 4 optical fibers in the loose tube, and the adjacent loose tubes are not tangent. In this case, a larger center can be used The strength member is used to overcome the problems that the central strength member of too small size is easy to break during the production of the optical cable and the yield of the finished product is low; at the same time, the tensile resistance of the optical cable is enhanced.

Embodiment 3

[0030] please see Figure 5 , and refer to Figure 1 to Figure 4 , an overhead optical cable, which is basically the same as that in Example 2, the difference lies in: the shape of the identification strip, which is easier to produce.

[0031] Of course, for the aerial optical cable described in the above-mentioned implementation examples 1-3, the loose tube can also be other multiples greater than 3; the optical fiber in each loose tube can be at least one; each loose tube is Tangent to the central reinforcement, each loose tube is tangent to the moisture barrier.

[0032] Of course, further, in the aerial optical cable mentioned above, the adjacent loose tubes are preferably tangent; they can also be non-tangent. In this case, only the size of the central strengthening member needs to be increased.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap