Honeycomb structured body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0207] Powder of α-type silicon carbide having an average particle diameter of 22 μm (7000 parts by weight) and powder of α-type silicon carbide having an average particle diameter of 0.5 μm (3000 parts by weight) were wet-mixed, and to 10000 parts by weight of the resulting mixture were added and kneaded 570 parts by weight of an organic binder (methyl cellulose) and 1770 parts by weight of water to prepare a mixed composition.

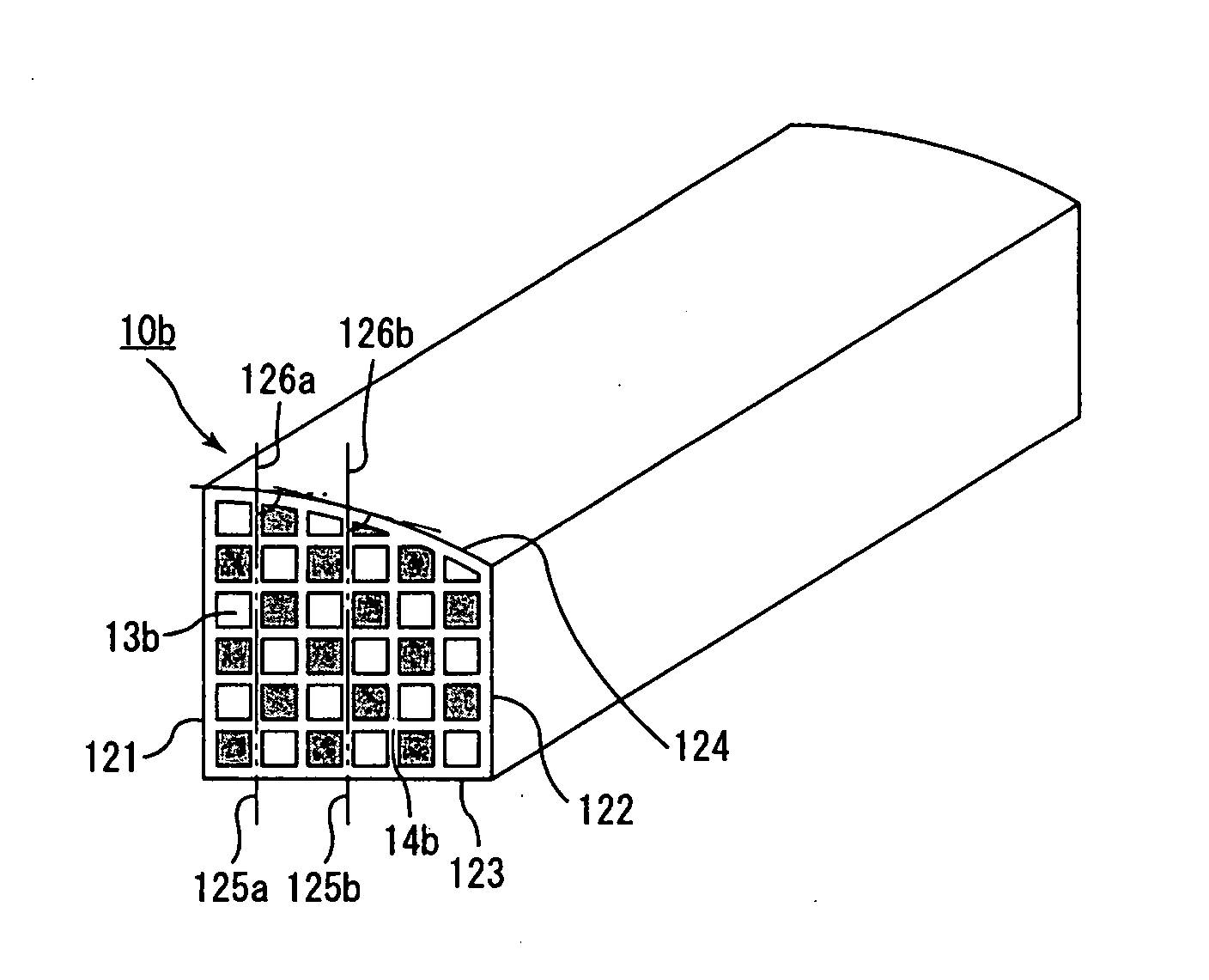

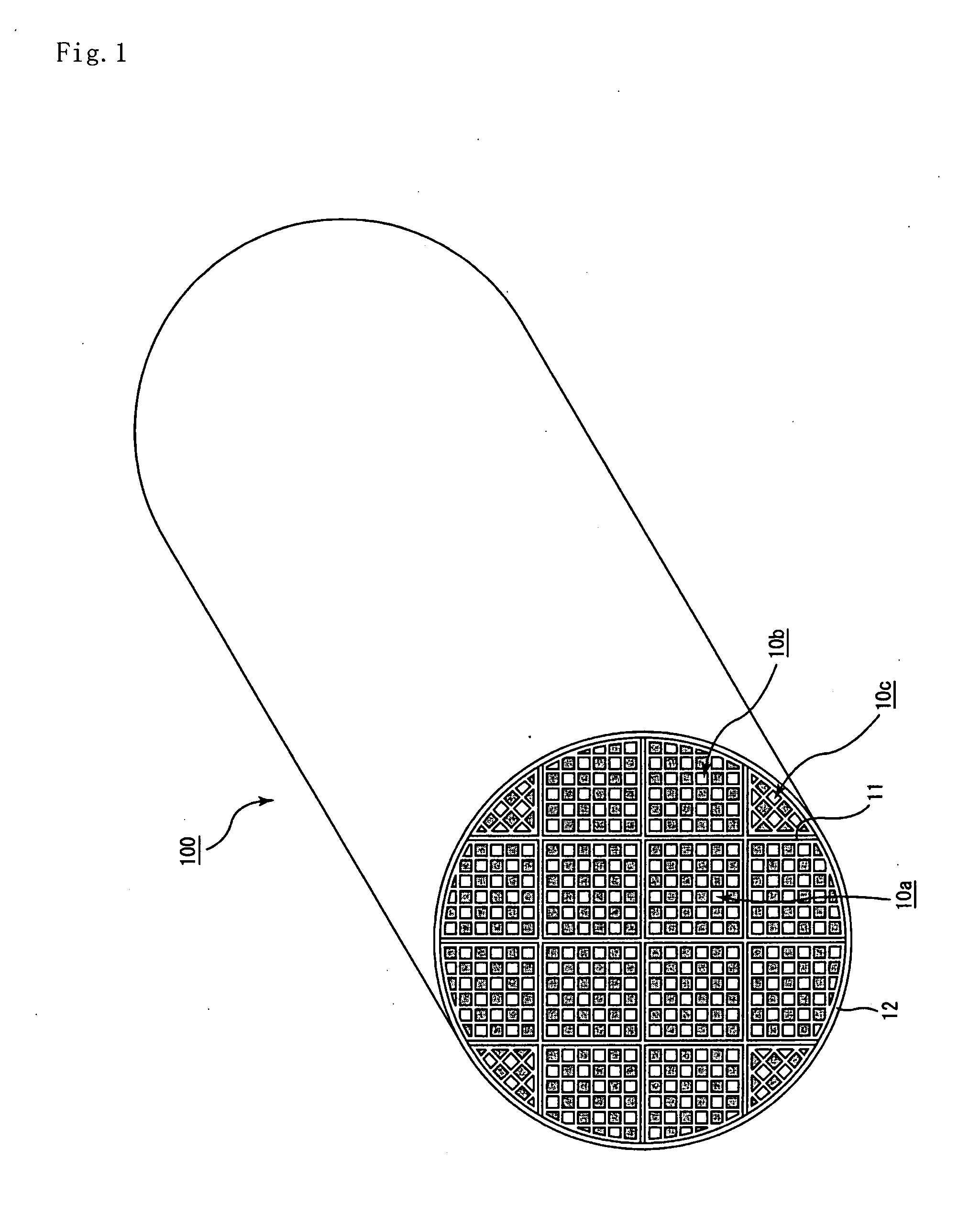

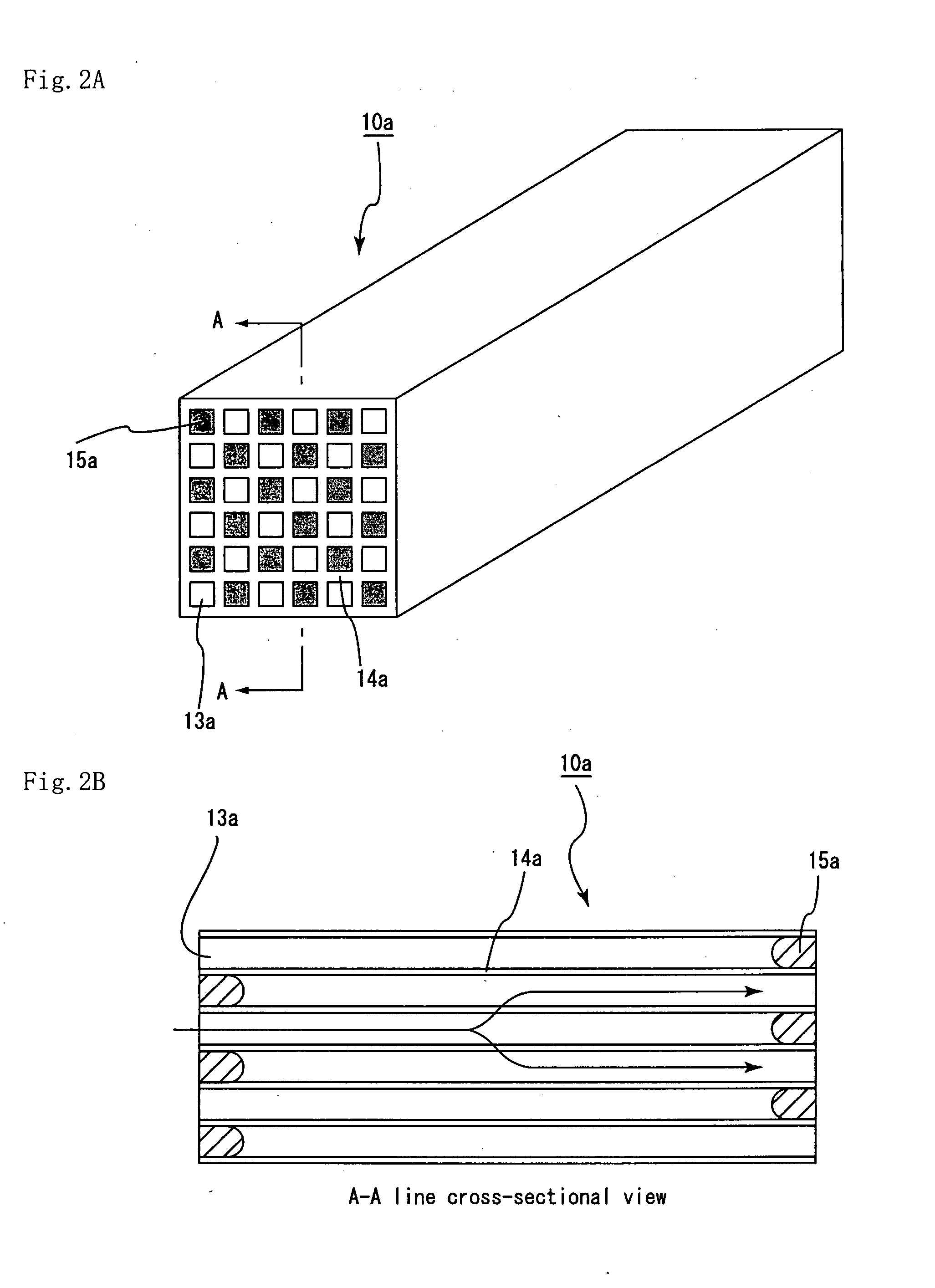

[0208] Next, to the above-mentioned mixed composition were added 330 parts by weight of a plasticizer (UNILUB, made by NOF Corp.) and 150 parts by weight of a lubricant (glycerin), and this was further kneaded, and then extrusion-molded to manufacture a rectangular pillar-shaped raw molded body (see FIG. 2A) which has cells each of which has a tetragonal shape on the shape at the perpendicular cross-section and is surrounded by cell walls that are in parallel with the peripheral edges, and a rectangular pillar shaped raw molded body which has cells each of whic

examples 2 to 4

[0221] Upon producing the honeycomb structural ceramic members, the same processes as Example 1 were carried out except that the shape of the member C was formed into a shape shown in Table 1-1 to manufacture a honeycomb structured body.

[0222] Here, in Table 1-1, “an angle formed relative to the peripheral edge” of the member A (the honeycomb structural ceramic member having a tetragonal profile on the shape at the perpendicular cross-section) refers to an angle formed between the straight line made by the cell walls and the peripheral edge. Moreover, “an angle formed relative to the straight line sandwiched by two straight lines” of the member B (the honeycomb structural ceramic member having a shape surrounded by three straight lines and one curve at the perpendicular cross-section) refers to an angle between the straight line formed by the cell walls and a straight line sandwiched by the two straight lines of the peripheral edge, “an angle formed relative to the tangent at the midd

example 5

[0223] Upon producing the honeycomb structural ceramic members, the same processes as those of Example 1 were carried out except that the shape of the member B was formed into a shape as shown in Table 1-1 so that a honeycomb structured body was manufactured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap