Linear compressor

a compressor and linear technology, applied in the direction of piston pumps, positive displacement liquid engines, pump components, etc., can solve the problems of low operation reliability and large mechanical loss caused by motion conversion, and achieve the effects of reducing deformation of cylinders, reducing frame size, and increasing cylinder siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

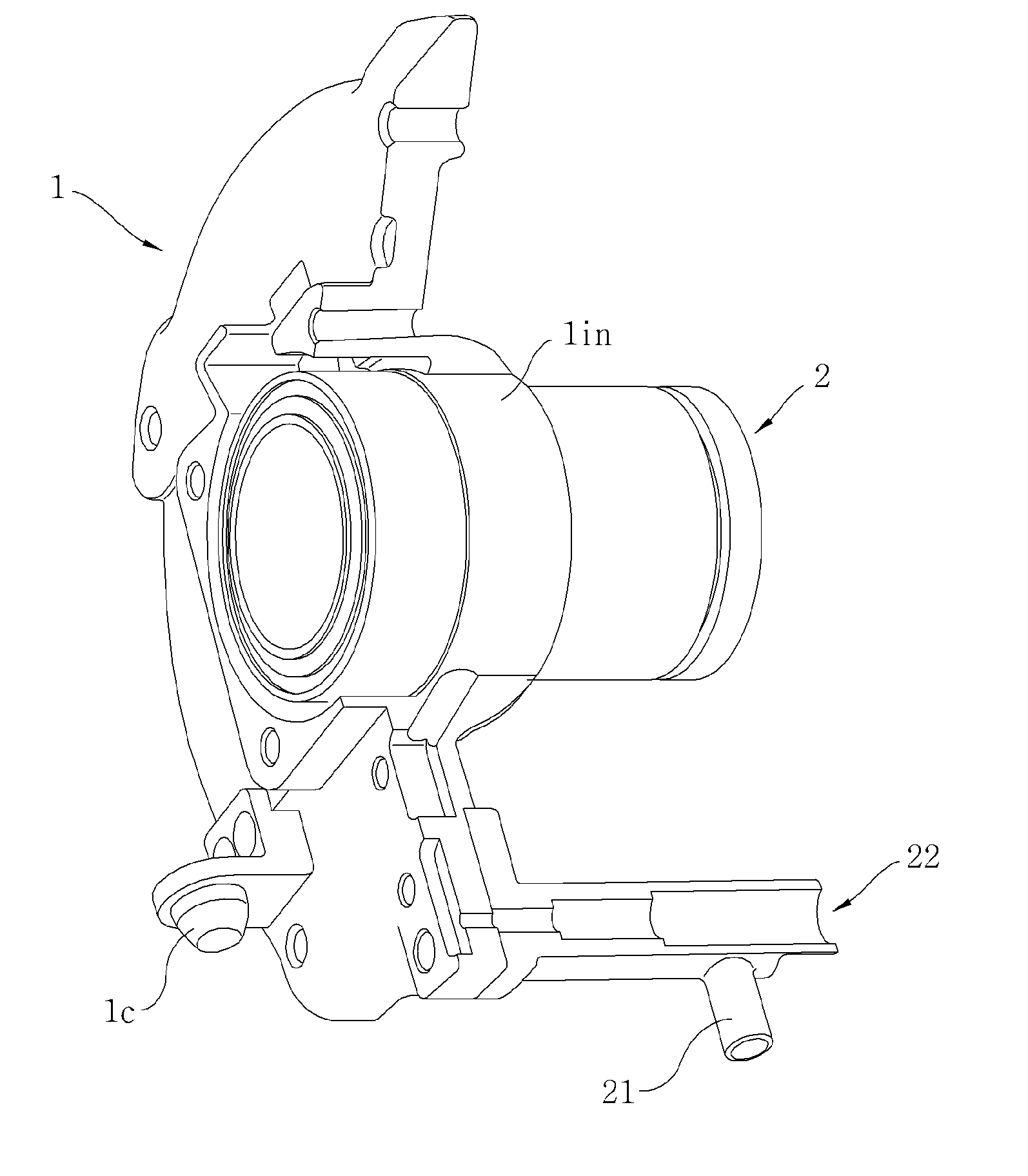

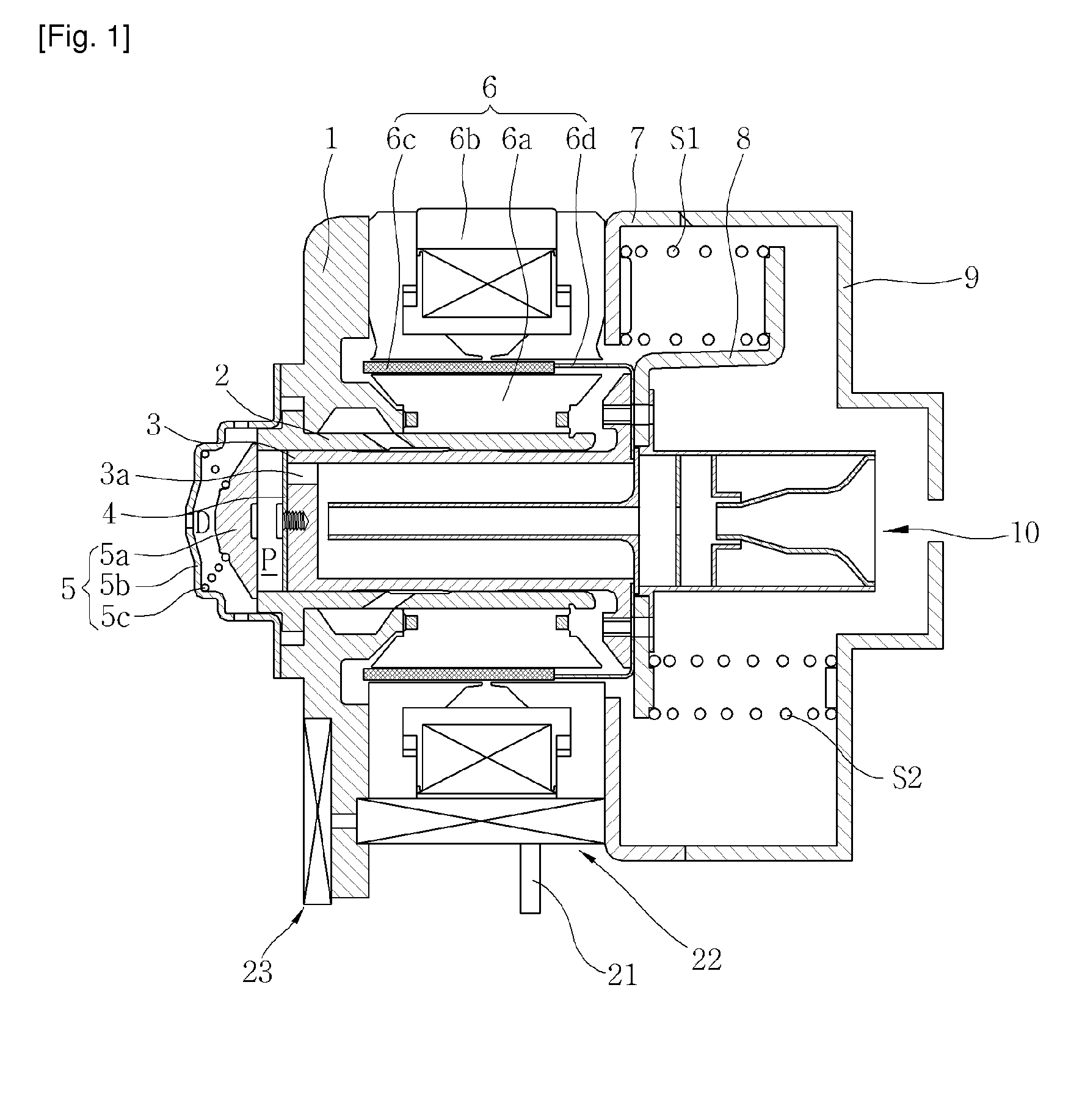

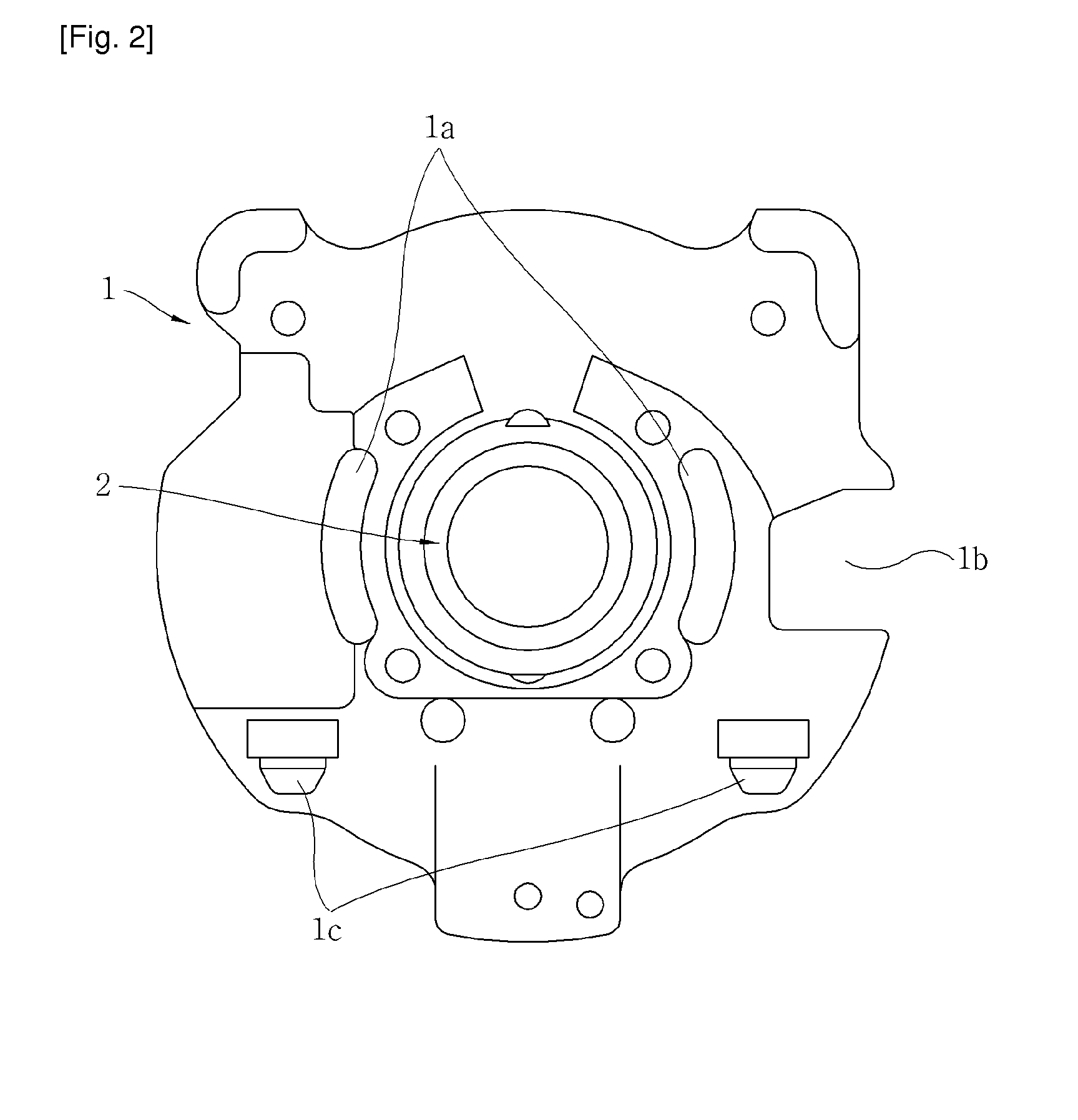

[0032]FIG. 5 is a view illustrating a linear compressor according to an embodiment of the present invention. The linear compressor 100 according to the present invention includes a cylinder 200, a piston 300, a linear motor 400 composed of an inner stator 420, an outer stator 440 and a permanent magnet 460, and an oil supply assembly 900 inside a shell 110 which is a hermetic container. When the permanent magnet 460 is linearly reciprocated between the inner stator 420 and the outer stator 440 due to a mutual electromagnetic force, the piston 300 connected to the permanent magnet 460 is linearly reciprocated together with the permanent magnet 460, and oil stored in the bottom of the shell 110 is pumped / supplied through the oil supply assembly 900 due to vibration of the piston 300 to thereby lubricate the cylinder 200 and the piston 300.

[0033]The i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap