Control method and system of compressor electric heating band in air conditioner

A technology of electric heating belt and control method, applied in pump control, machine/engine, mechanical equipment, etc., can solve problems such as damage to the insulation layer of compressor motor windings, interphase short circuit, compressor damage, etc., to reduce standby power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes specific embodiments of the present invention with reference to the accompanying drawings.

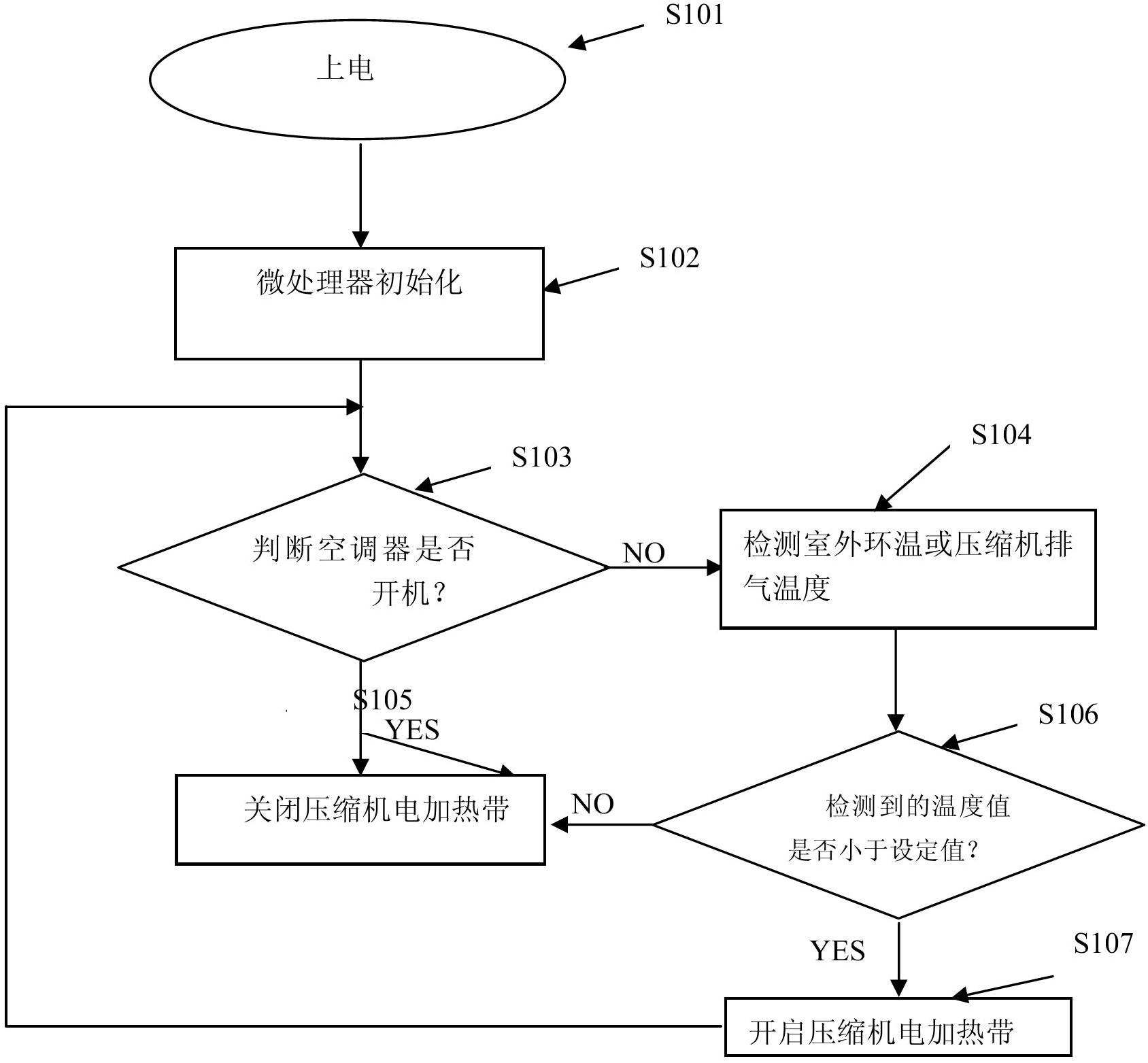

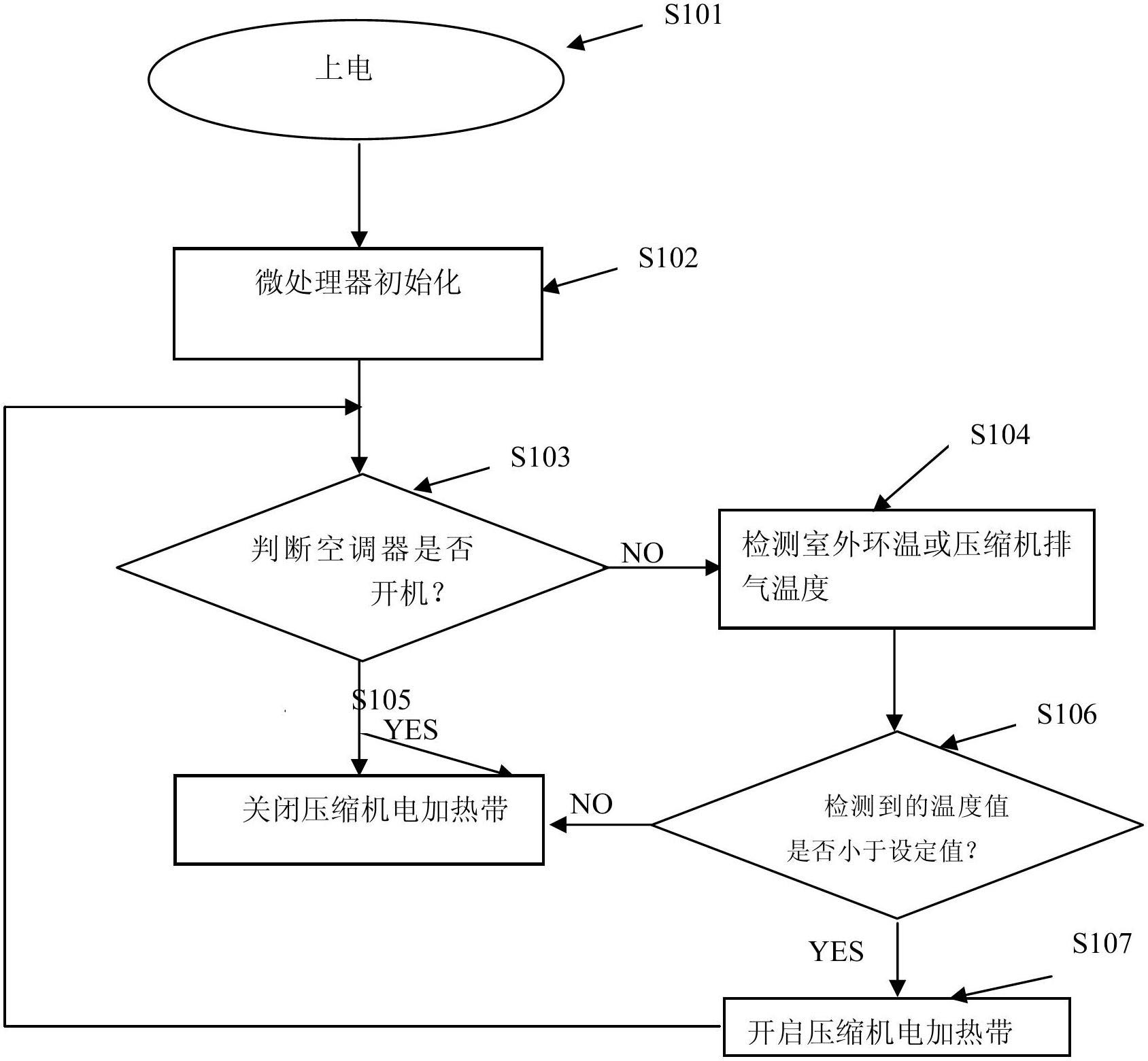

[0022] see figure 1 Describe an example of the control method of the compressor electric heating belt in the air conditioner of the present invention, which includes: step S101, power on the air conditioner; then turn to step S102, initialize the microprocessor; then turn to step S103, determine whether the air conditioner boot. Further, according to step S103 judgment result, be divided into following two situations: (1) if step S103 judges that air conditioner standby (NO), then proceed to step S104 and detect outdoor ambient temperature or compressor exhaust temperature; then enter step S106 judgment Whether the detected temperature value is less than the set value; if step S106 judges that the detected value is less than the set value, then enter step S107 to open the compressor electric heating belt, if step S106 judges that the detected value is great

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap