Pneumatic two-fluid grouting pump

A double-fluid grouting and ballooning technology, which is applied in the direction of pumps, piston pumps, machines/engines, etc., can solve the problem of inaccurate grout ratio and achieve the effect of reducing purchase costs and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

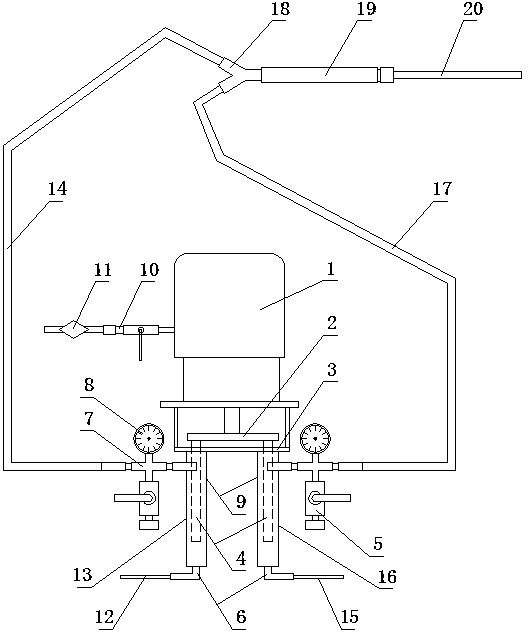

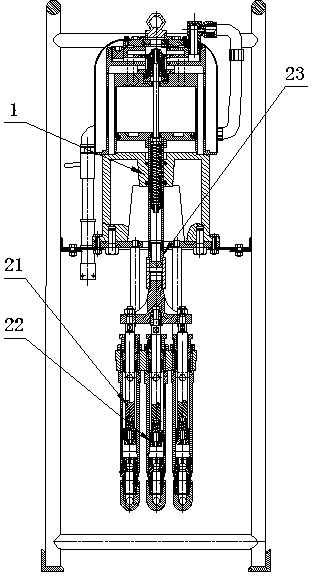

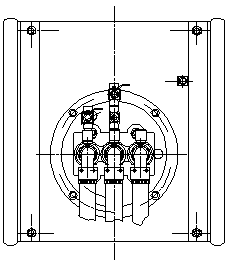

[0021] The pneumatic two-fluid grouting pump of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] As shown in the accompanying drawings, the structure of the pneumatic double-liquid grouting pump of the present invention includes an air motor 1, a plunger pump 9, a mixing tube 19 and an injection tube 20, the filter 11 is connected to the inlet ball valve 10, and the inlet ball valve 10 is connected to Air motor 1, the air motor 1 is connected with the piston plate 2 through the connecting rod 23, the piston plate 2 is connected with three pistons 4, the air motor 1 is set on the piston frame 3, and the three pistons are all connected to the piston plate set on the piston frame And inside the pump body are three plungers corresponding to the piston. The suction end of the plunger pump is provided with an elbow 6, and the pump liquid end of the plunger pump is connected with a four-way pipe 7, and the four-way pipe 7 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap