Removal method of outdoor hanging steps

A technology of steps and steel pipes, which is applied in the field of outdoor suspended steps demolition, can solve the problems of high difficulty in safety maintenance, low construction efficiency, and high risk, so as to improve construction efficiency and engineering waste handling efficiency, improve construction safety, and avoid passive damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0042] Example 1. The width of the large step is 10m, the span is 8m, the beam height is 0.8 / 1.29m, the beam width is 0.3m, and the plate thickness is calculated as 0.15m

[0043] Board: 10m*8m*0.15m*25KN / m 3 =300KN=30t

[0044] Beam: (4m*0.3m*0.8m+4m*1.29m*0.3m)*25KN / m 3 =62.7KN; 0.3m*0.8m*10m*25=60KN 62.7KN*5+60KN=373.5KN=37.35t

[0045] (1) Weight calculation of large steps:

[0046] Total weight: 30+37.35=67.35t

[0047] (2) End (1.5m) weight: 60KN+(255+300)*1.5 / 8=164KN=16.4t

[0048] (3) The back weight of the steel pipe frame is calculated as 60% of the total weight

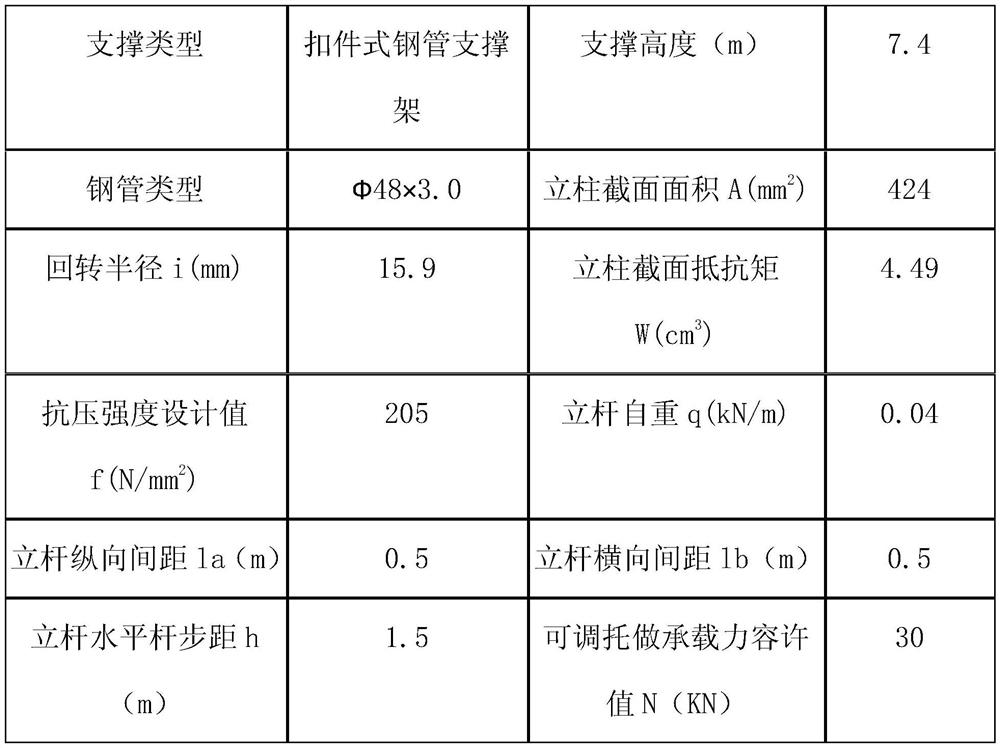

[0049] 1. Steel pipe characteristics

[0050]

[0051] 2. The load on each pole

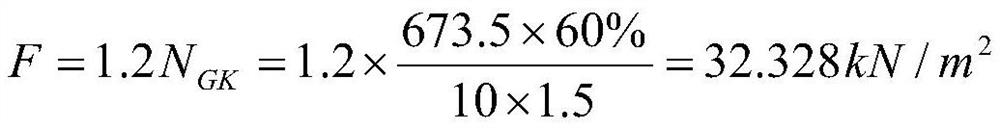

[0052] 1) Large step load design value:

[0053]

[0054] The maximum vertical force design value of the pole: N = 32.328 × 0.5 × 0.5 = 8.082kN

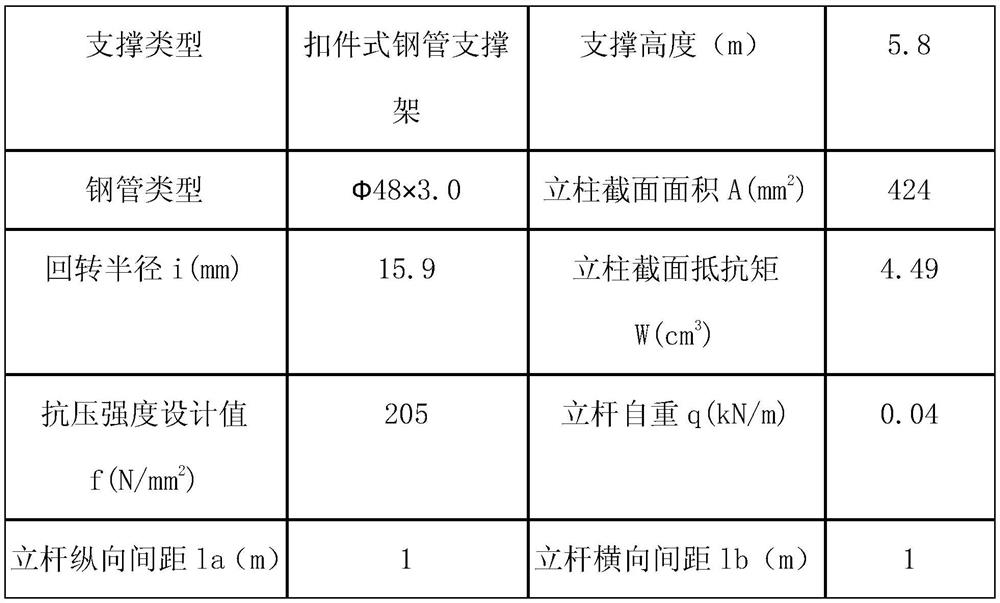

[0055] 3. Pole stiffness and stability

[0056] Assuming that 60% of the load in the large step area is borne by the steel pipe scaffolding, according to the "Te

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap