Double-disk detonator automatic assembling machine buckling assembling pressing device

A technology of pressing device and assembly machine, applied in the direction of detonator, offensive equipment, etc., can solve the problems of lack of automatic production equipment, performance and quality problems, etc., to expand the scope of assembly production, reduce density, and reduce manufacturing and management costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

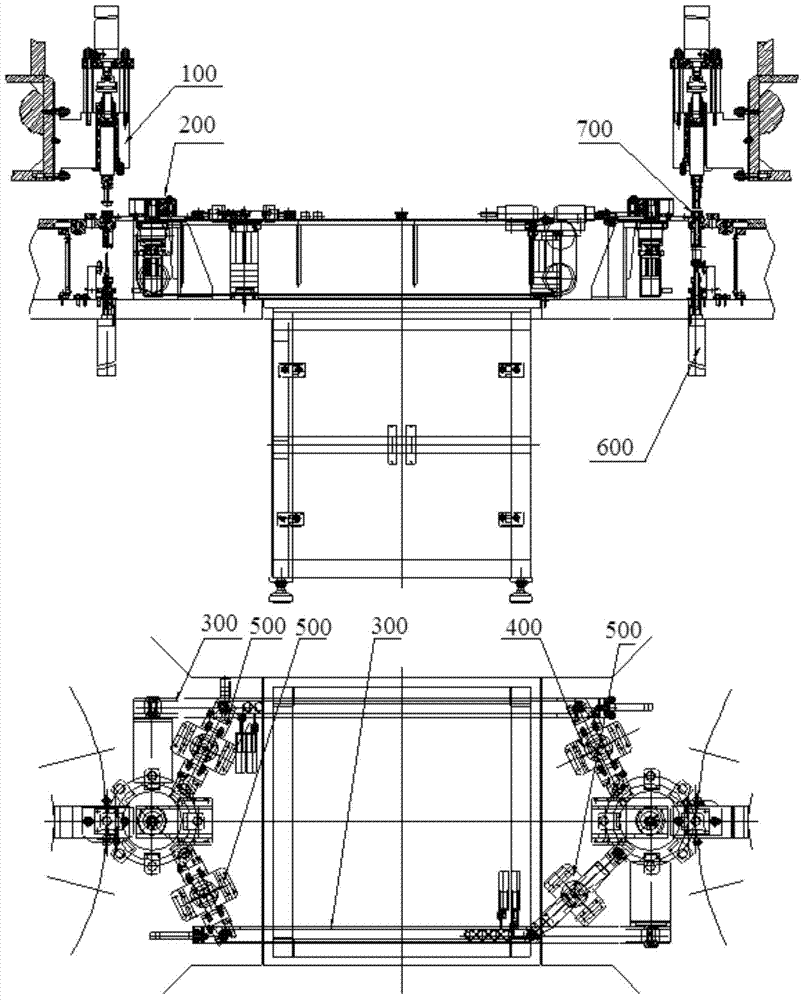

[0041] see figure 1 , this embodiment provides a double-disk detonator automatic assembly machine snap-fit assembly pressing device, which is composed of two 24-station disc-type detonator automatic assembly machines (A, B) and a snap-fit assembly pressing device; To meet the needs of the detonators produced, a snap-fit assembly press-fit device was developed. Through the newly developed snap-fit assembly press-fit device, the above-mentioned two 24-station disc detonator automatic assembly machines (A, B) are connected, and the assembly and production are complicated. composite detonators.

[0042] In this embodiment, the two 24-station disc detonator automatic assembly machines are selected from the 24-station disc detonator automatic assembly machine A introduced by the applicant from Lachese, Belgium in 2004, and the self-developed 24-station detonator. Automatic assembly machine B.

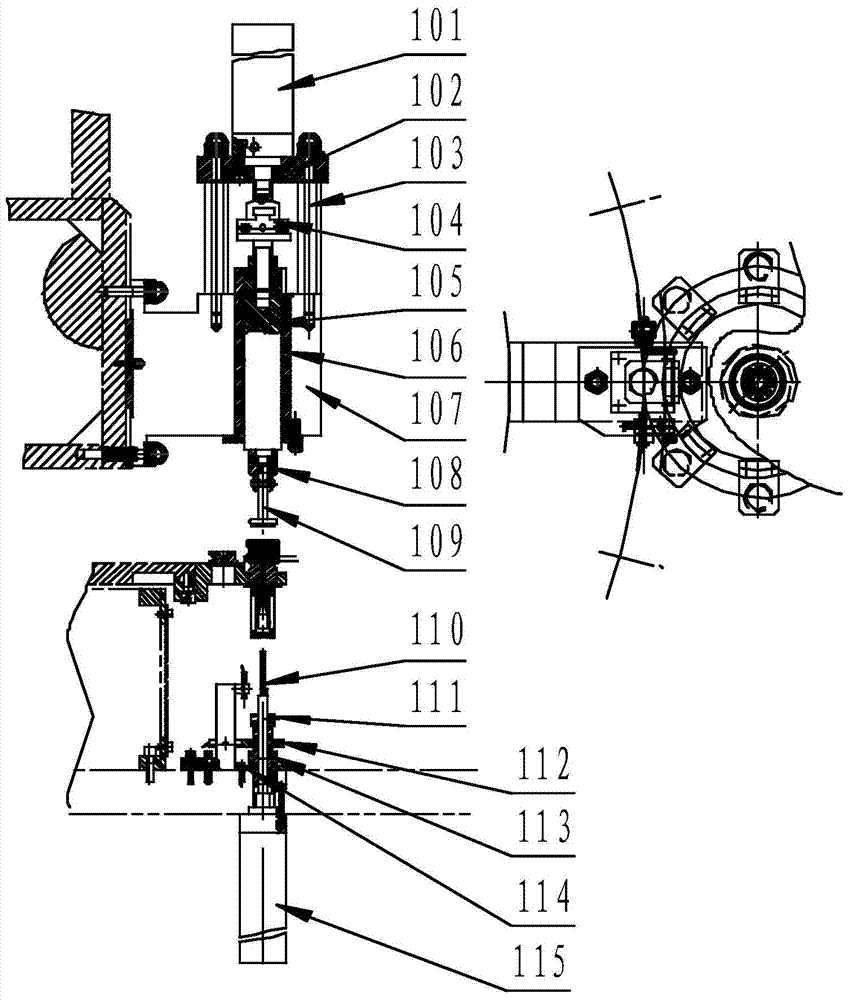

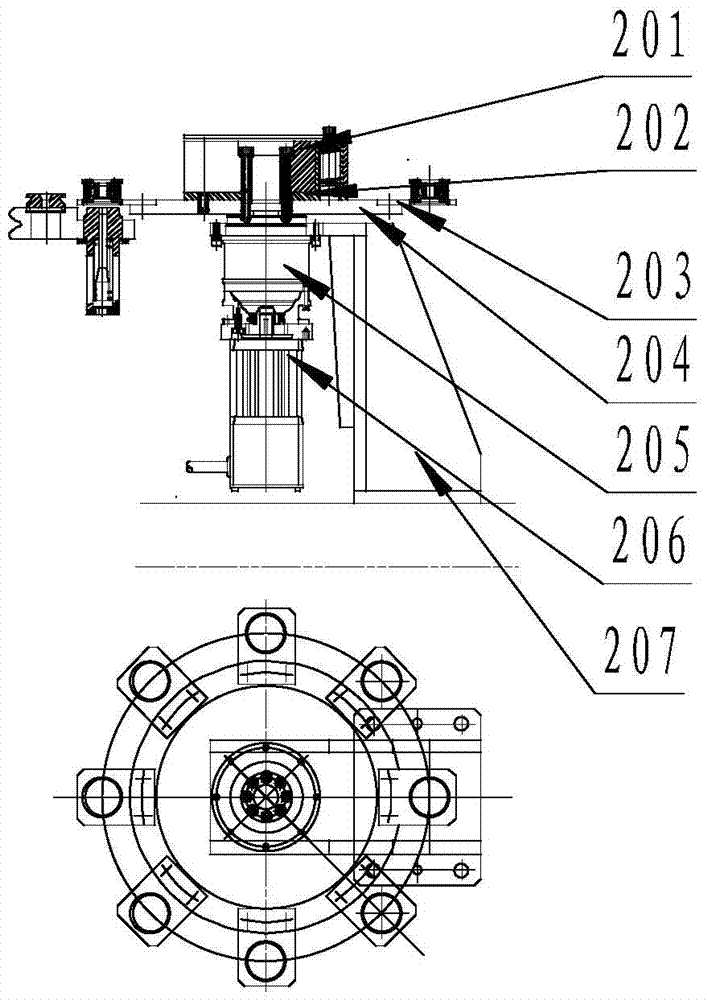

[0043] The snap-fit assembly press-fit device mainly consists of a charge reinfo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap