Coke oven mobile motor vehicle interlocking automatic control system

An automatic control system and control system technology, applied in coke ovens, oven safety devices, petroleum industry, etc., can solve problems such as backward coke pushing operation and harsh environment of coking plants, achieving no accumulation of errors, low construction and maintenance costs, Reliable effect of furnace number identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

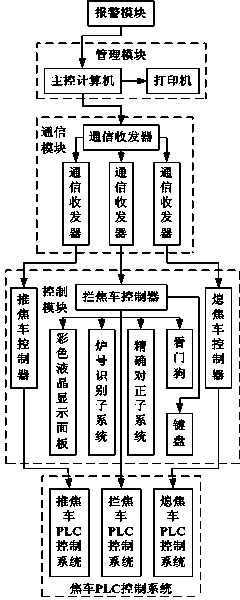

[0024] A coke oven mobile locomotive interlock automatic control system, such as figure 1 As shown, it includes a management module, a communication module, a control module, an alarm module and a coke car PLC control system, the management module includes a main control computer and a printer, the communication module uses a communication transceiver, and the control module includes a coke pushing car controller, coke-blocking car controller, coke-quenching car controller, furnace number identification subsystem and precise alignment subsystem, wherein the alarm module is connected to a main control computer, the main control computer is connected to a printer, and the main control computer A communication transceiver is connected, and the communication transceiver is respectively connected with the controller of the coke pushing vehicle, the control

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap