Fully-automatic numerical control feeding device

A feeding device, a fully automatic technology, applied in the field of feeding device and automatic numerical control feeding device, can solve the problems of poor dimensional accuracy of materials, feeding length error, etc., to save detection devices, improve work efficiency, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

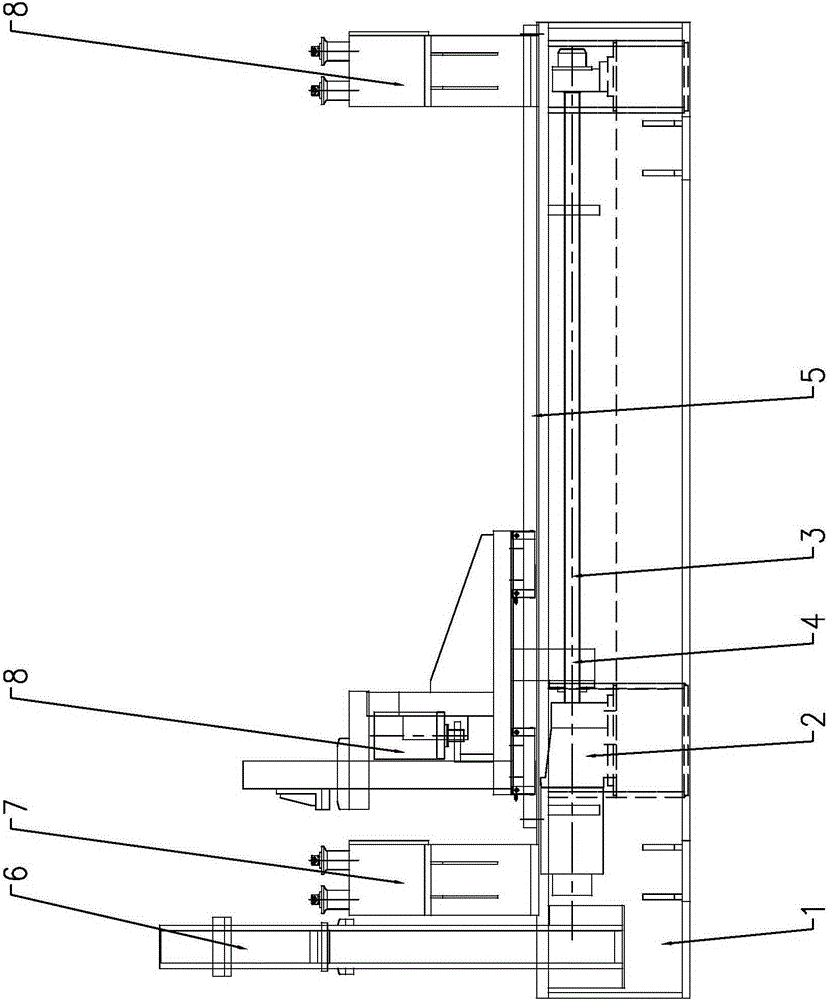

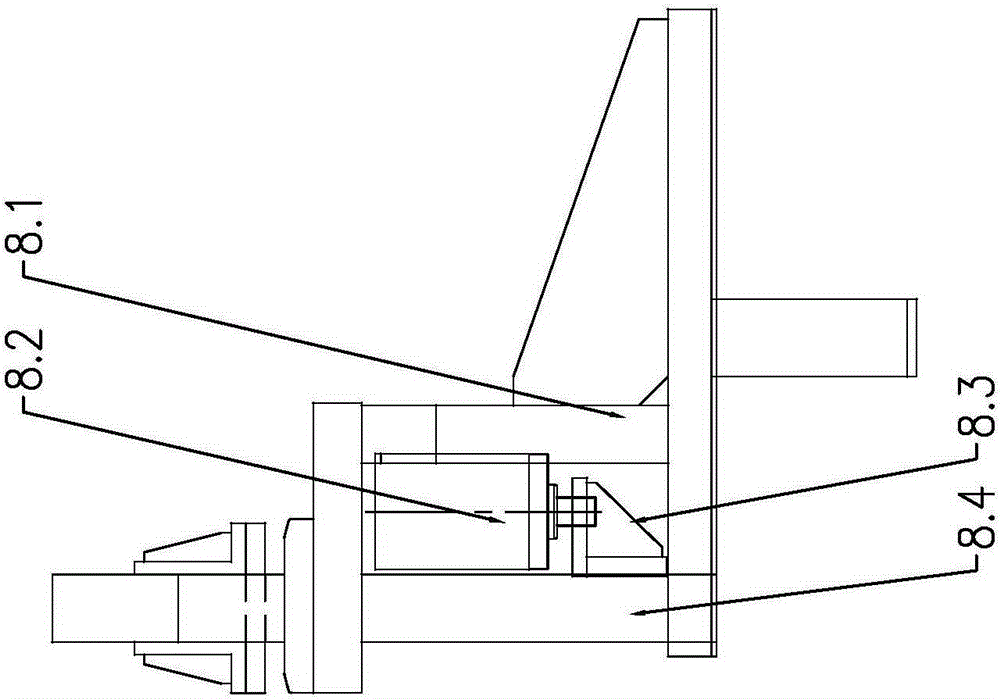

[0016] Such as figure 1 As shown, the present invention mainly includes a base 1, a servo motor 2, a screw 3, a screw nut seat 4, a linear slide rail 5, a fixed clamping device 6, a front centering device 7, a traveling clamping device 8 and a rear centering Device 9, the base 1 is provided with a fixed clamping device 6, a front centering device 7, a linear slide rail 5 and a rear centering device 9 in sequence from front to back, and the linear slide rail 5 is slidably connected with a traveling clamping device 8. The lower end of the walking clamping device 8 is connected to the screw nut seat 4, and the screw nut seat 4 is connected to the screw mandrel 3, and one end of the screw mandrel 3 is connected to the servo motor 2 fixed on the base 1.

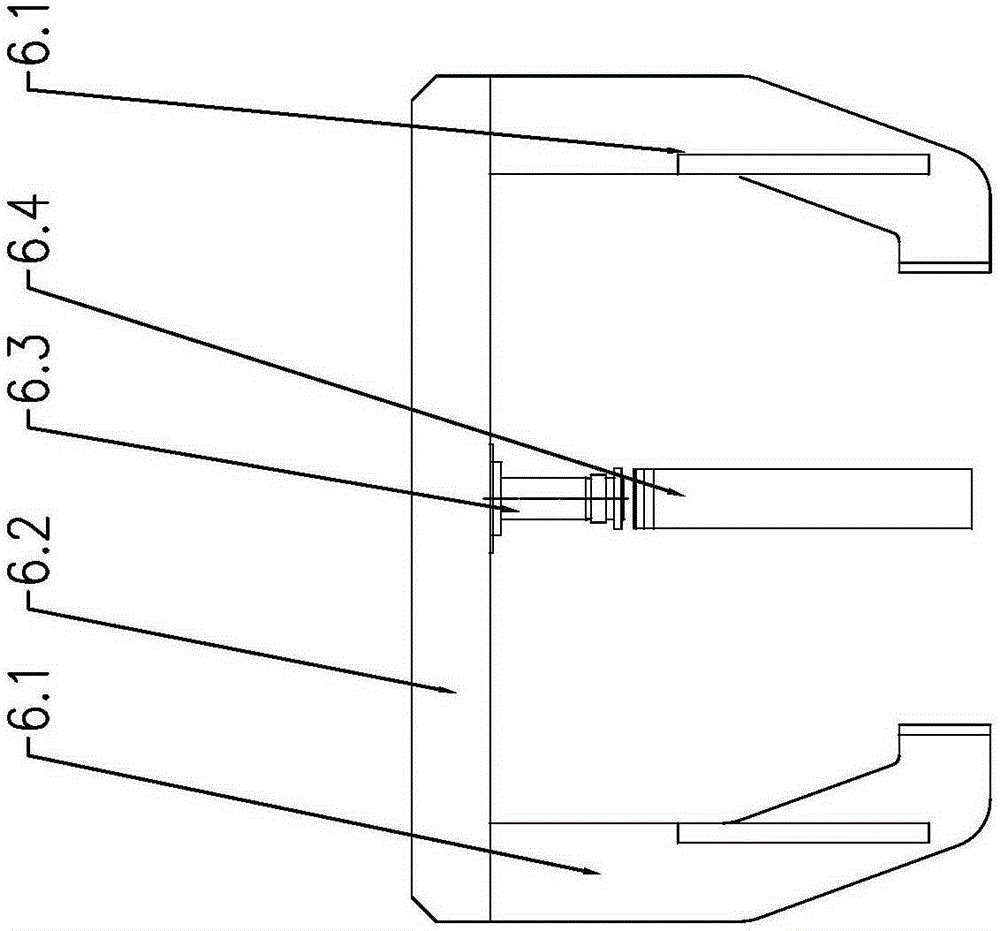

[0017] Such as figure 2 As shown, the fixed clamping device 6 includes a side column 6.1, a beam 6.2, a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap