Adjustable copper pipe bending machine

A bending machine, adjustable technology, applied in the direction of metal processing equipment, feeding device, positioning device, etc., can solve the problems of poor bending effect, cumbersome processing, and inability to bend, so as to save money and reduce human resources , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be further described in detail below.

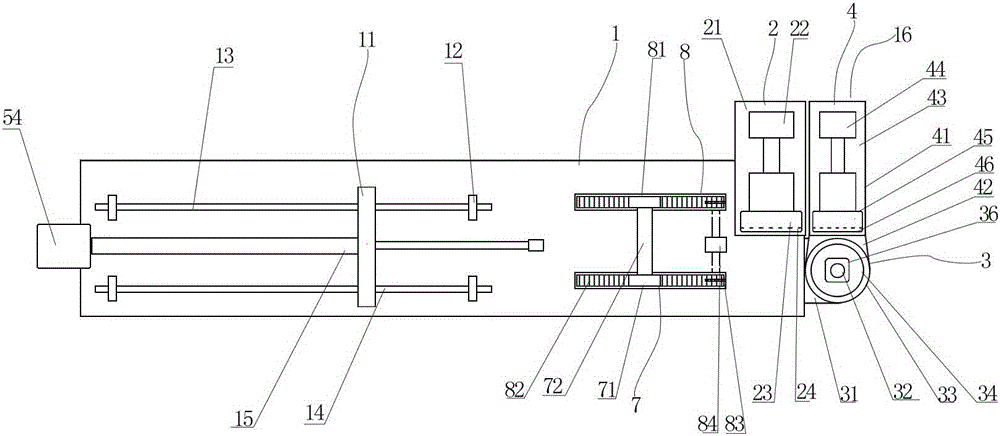

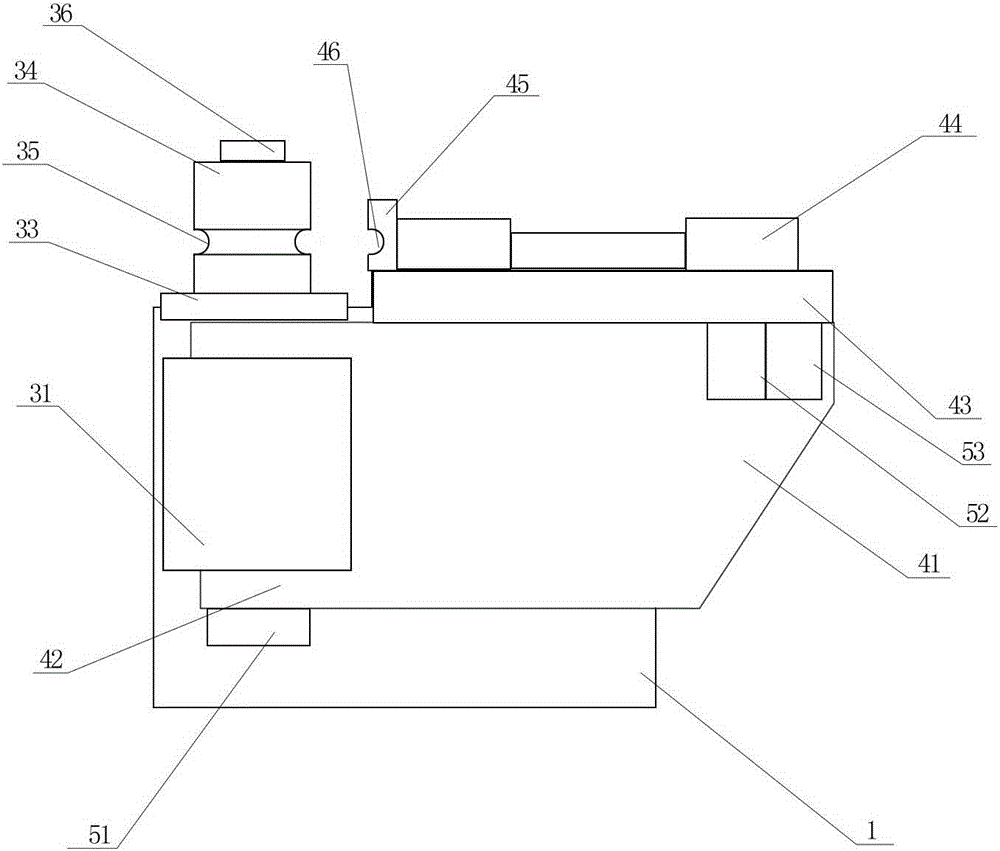

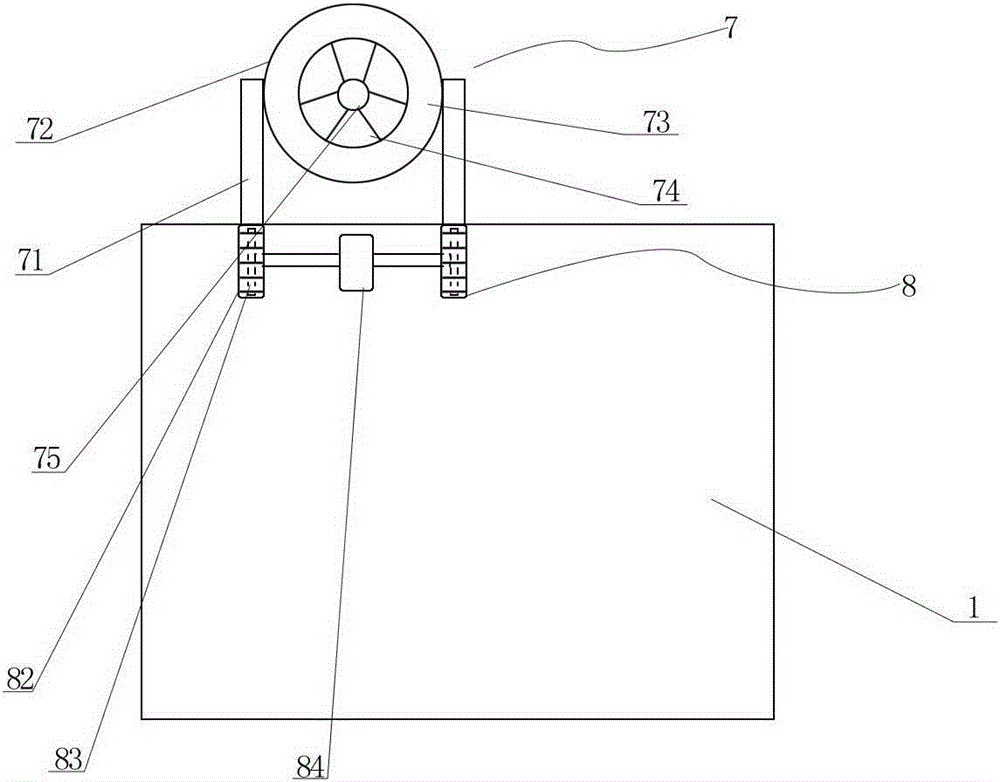

[0019] Such as Figure 1 to Figure 3 As shown, an adjustable copper tube bending machine of the present invention includes a frame 1, and is characterized in that: the frame 1 is provided with a pushing device 11 and a bending device 16 arranged on one side of the pushing device 11, and the folding A rotating mechanism 7 is arranged between the bending device 16 and the pushing device 11. The bending device 16 includes a first bending part 2 arranged on the right side of the top of the frame 1, a rotating part 3 arranged on the right side of the frame 1 and a connection The second bending part 4 of the rotating part 3, the first bending part 2 and the second bending part 4 are arranged in parallel, and the lower part of the rotating mechanism 7 is provided with an adjusting mechanism 8, which includes Two grooves 81, the groove 81 is provided with a rotating toothed belt 82, one sid

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap