Feeding device for electric power copper pipe flaring machine

A flaring machine and copper tube technology, applied in the field of tube material processing, can solve the problems of many sources of failure, long length and large space occupation, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

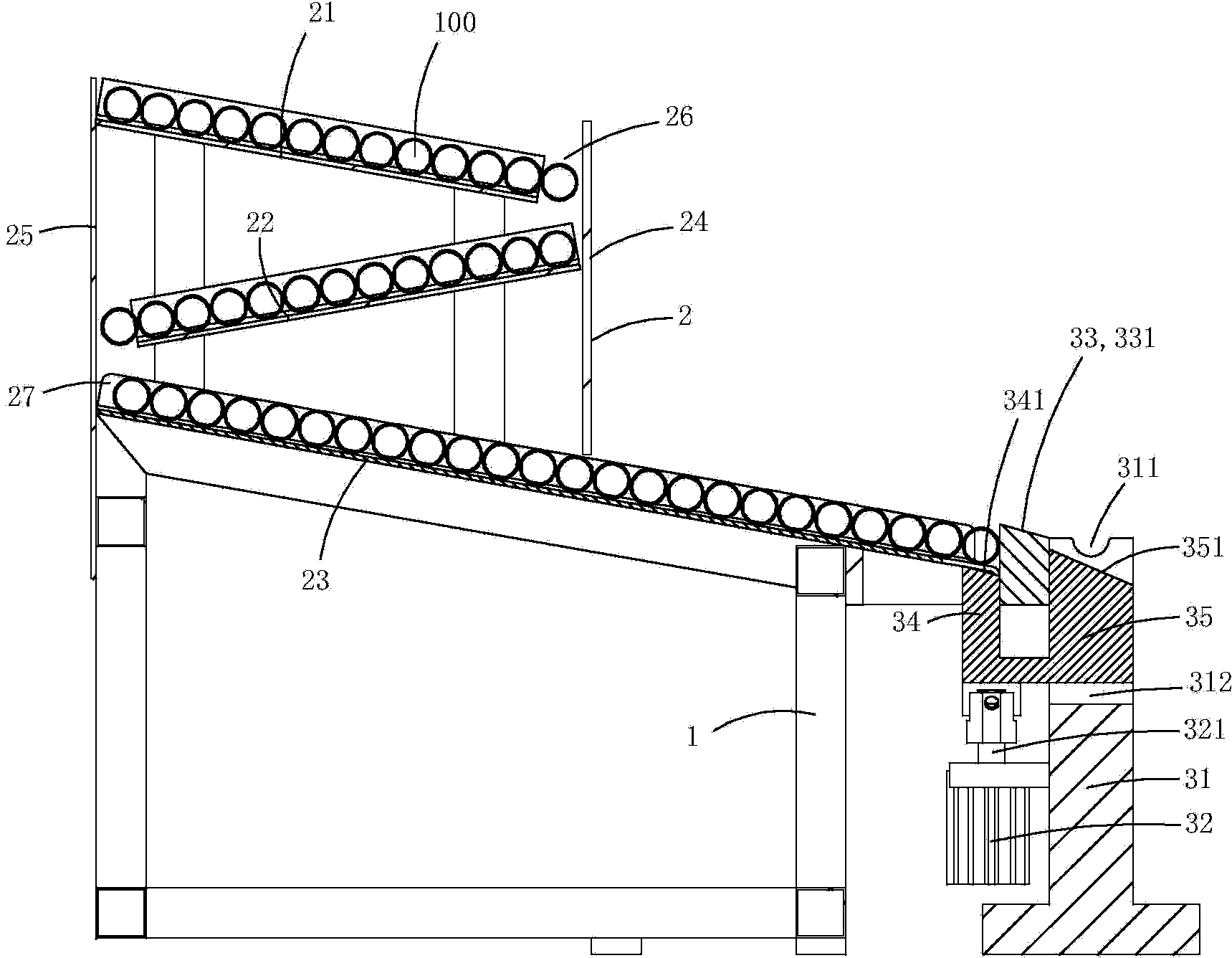

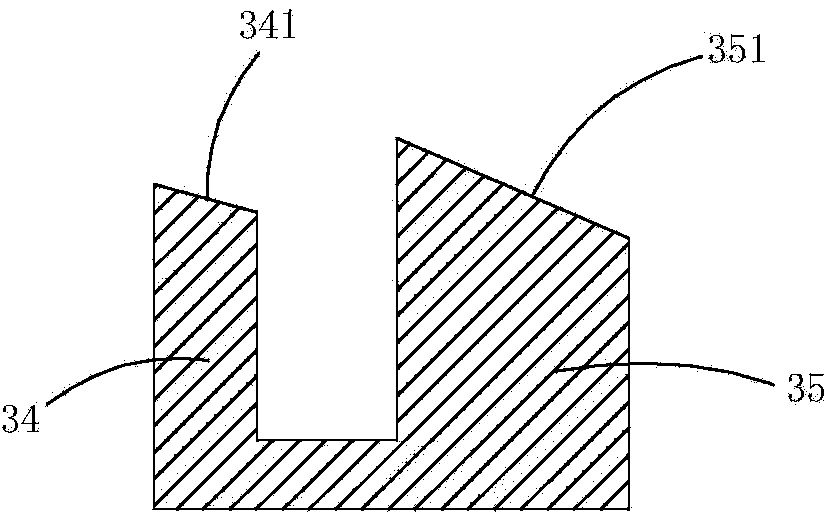

[0015] figure 1 with figure 2 A specific embodiment of the present invention is shown, in which, figure 1 Is a schematic diagram of the structure of the present invention; figure 2 for figure 1 A structural schematic diagram of the feeding top column and the discharging top column in the ejecting device shown.

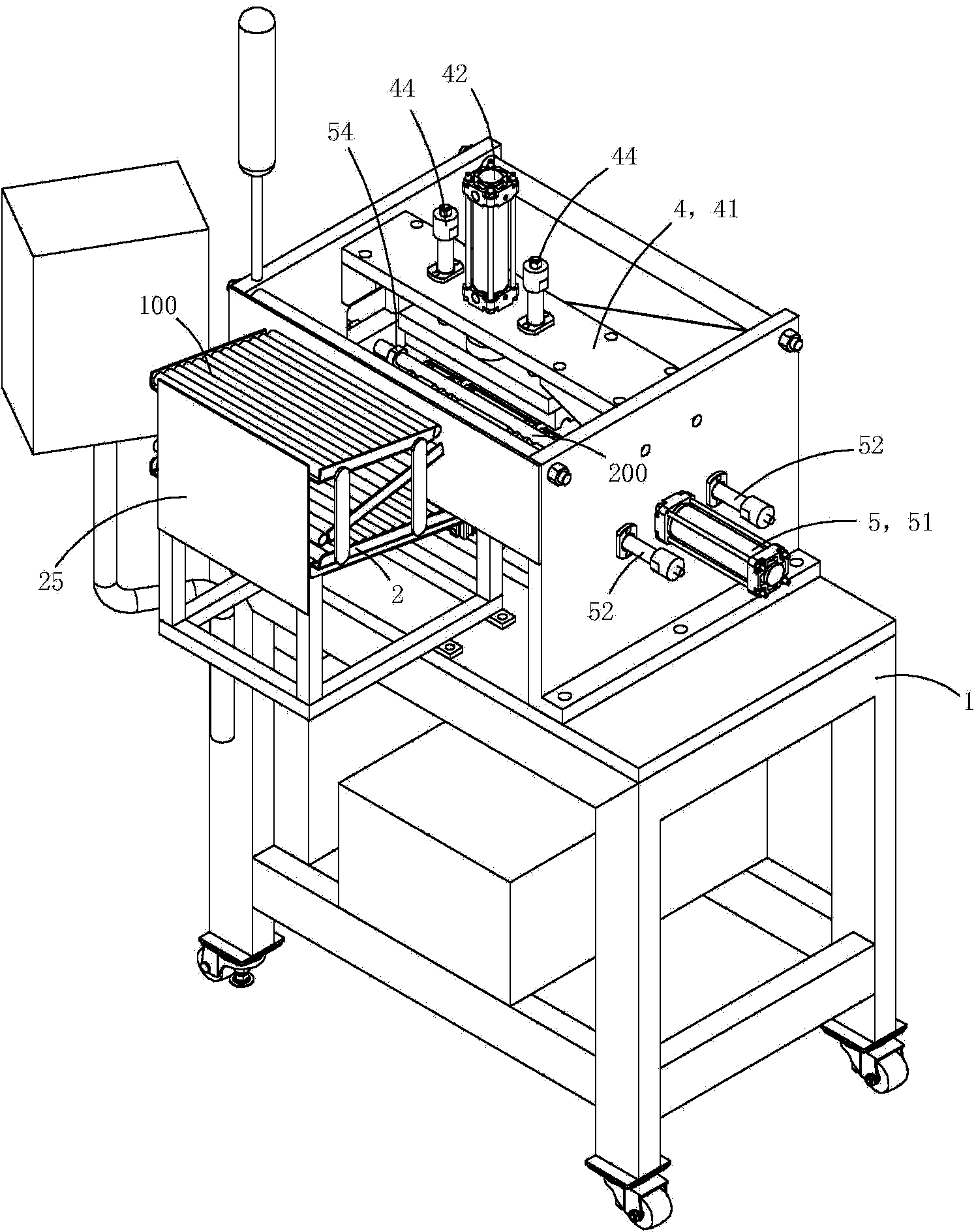

[0016] This embodiment is a feeding device for the electric copper pipe flaring machine, see Figure 1 to Figure 2 As shown, the bracket 1, the feeding mechanism 2 and the ejecting mechanism 3 are included.

[0017] The conveying mechanism includes a first conveying plate 21, a second conveying plate 22, a third conveying plate 23, a front baffle 24 and a rear baffle 25, the first conveying plate, the second conveying plate, and the The cross-sectional shape of the three conveying plates is U-shaped; the first conveying plate, the second conveying plate, and the third conveying plate are all inclined at an angle with the horizontal plane, and combined to form an inclined Z-sh

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap