Feeding process and feeding device for straightening machine

A technology of feeding device and straightening machine, which is applied in the direction of feeding device, positioning device, storage device, etc., and can solve the problems of not being suitable for large-sized pipes, only centering, and large impact force of side feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

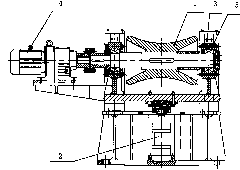

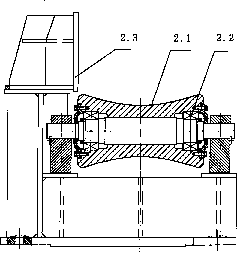

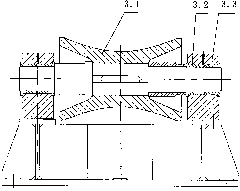

[0033] Such as figure 1 , 2 , 3, 4, and 5 show: a kind of straightening machine distribution process, its steps are as follows:

[0034] 1. Three different types of roller devices, lifting roller device (1), fixed roller device A (2), and fixed roller device B (3), are used to cooperate, arrange and combine to form a feeding system, which is used to complete the tube and bar material. Receive, move, and center the tubes and bars into the straightening machine;

[0035] 2. The order of arrangement and combination of the feeding system is: fixed roller device B (3), lifting roller device (1) and several groups of rollers composed of fixed roller device A (2) and lifting roller device (1) The devices are arranged in sequence;

[0036] 3. The feeding system is arranged in sequence, the combination of the lifting roller device, the fixed roller device A and the fixed roller device B is combined, and the feeding system is formed by the spacing type arrangement combination;

[0037]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap