Punching device applied to field of automobile manufacturing

A punching device and automobile manufacturing technology, applied in the direction of manufacturing tools, feeding devices, storage devices, etc., can solve the problems of slow manual insertion and removal, low work efficiency, and clamping of hands, so as to improve safety, Improved work efficiency and ease of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

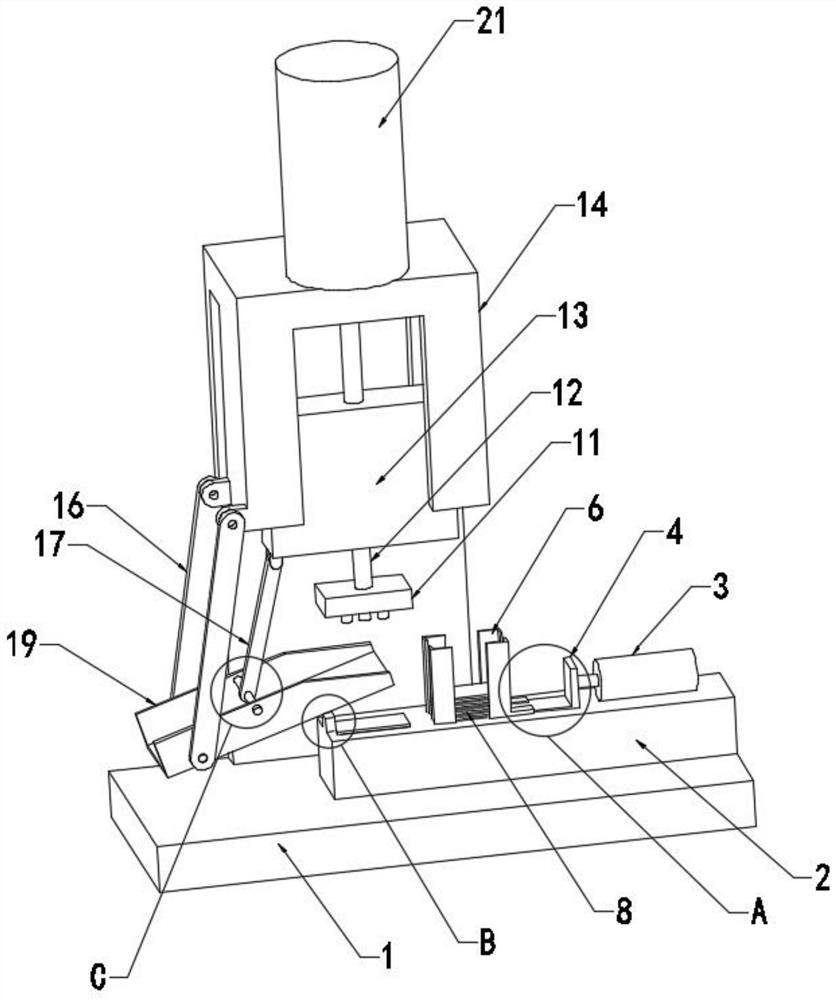

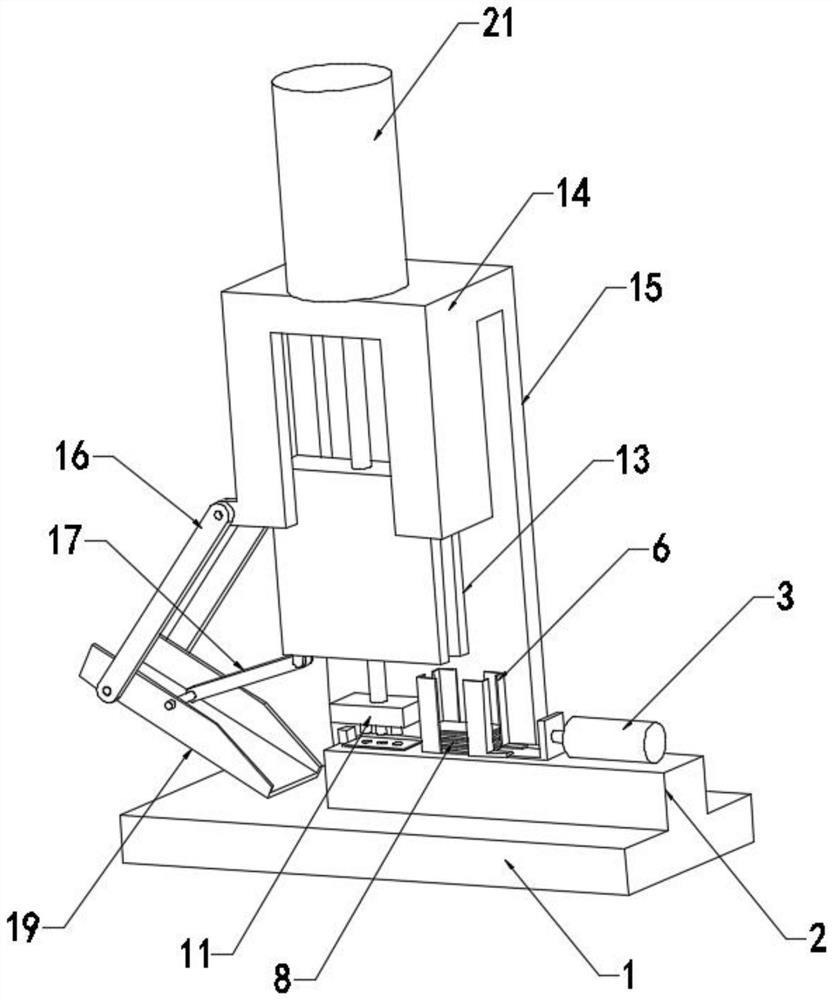

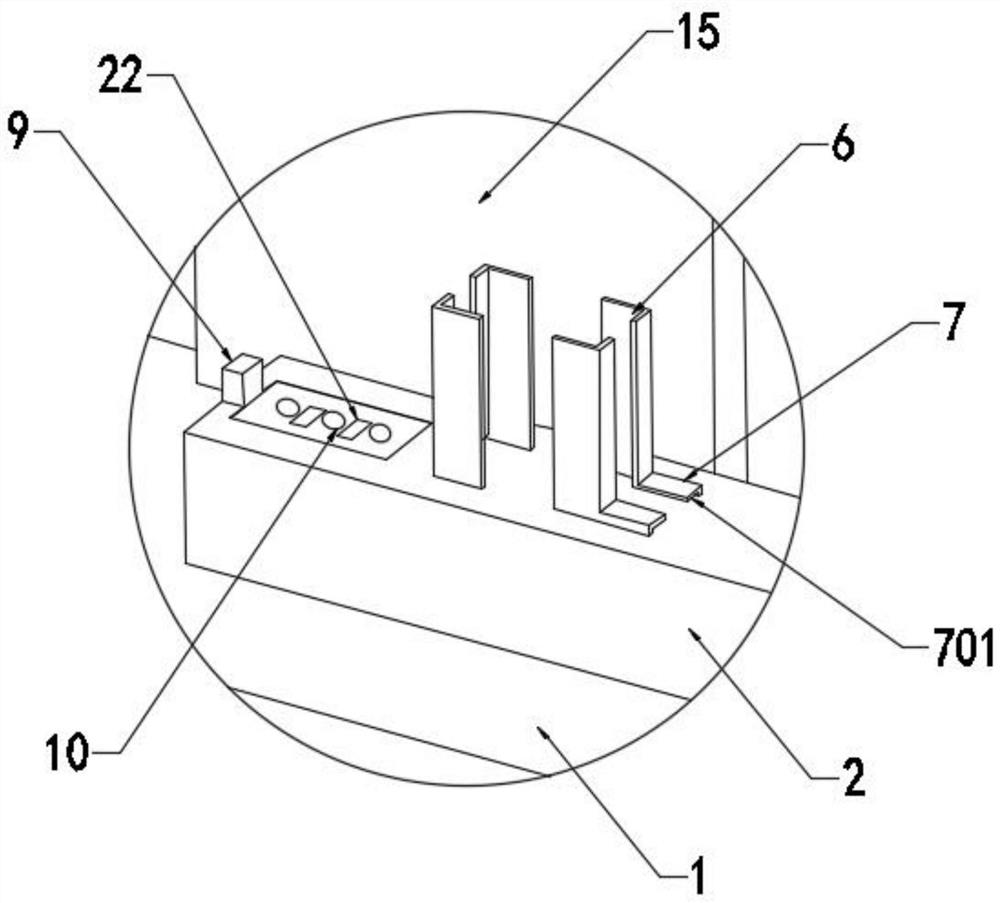

[0047] see Figure 1-10, the present invention provides a technical solution: a punching device used in the field of automobile manufacturing, including a base 1, a mounting base 2 is fixedly mounted on the top of the base 1, a lower module 10 is fixedly mounted on the mounting base 2, and a lower module 10 is fixedly mounted on the mounting base 2. The material frame 6 and the fixed block 7 are fixedly installed, and the bottom of the material frame 6 and the fixed block 7 is provided with a first groove 701, and the material frame 6 is provided with a plurality of stacked workpieces 8, and the mounting seat 2 is provided with the first groove 701. A push plate 5 that moves in a groove 701, a cylinder 3 is fixedly installed on the mounting seat 2, a mounting block 4 is fixedly mounted on the piston rod of the cylinder 3, the mounting block 4 is fixedly connected with the pushing plate 5, and the mounting block 2 is fixedly installed with The limit block 9 that restricts the move

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap