Wafer blanking production equipment and processing method

A technology for production equipment and wafer processing, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of hidden dangers to personnel safety, low work efficiency and low material rate, and reduce production processes, labor intensity and Potential safety hazards and rapid conversion of product specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

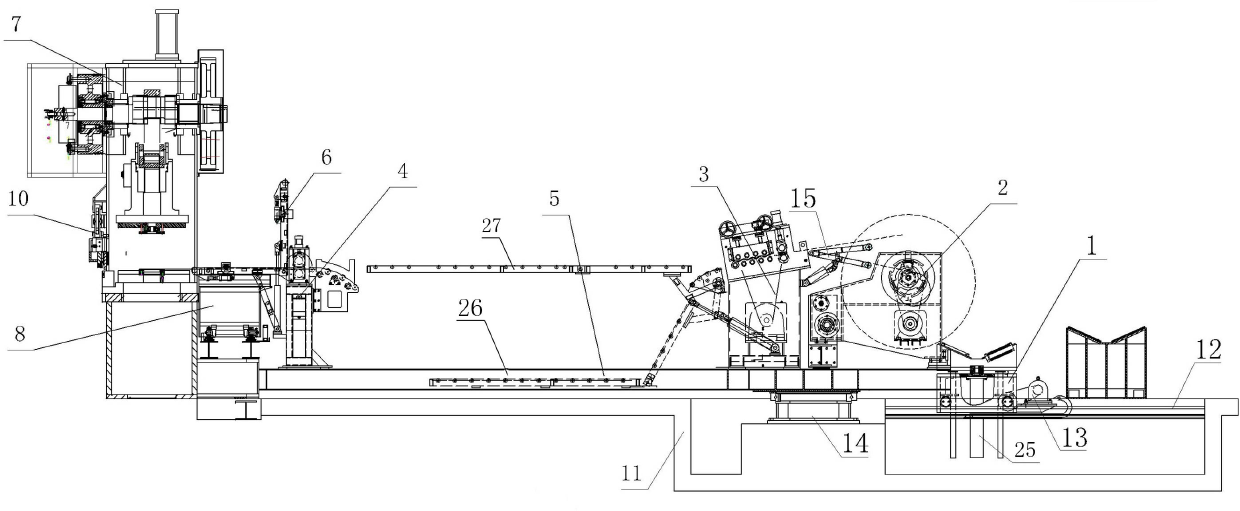

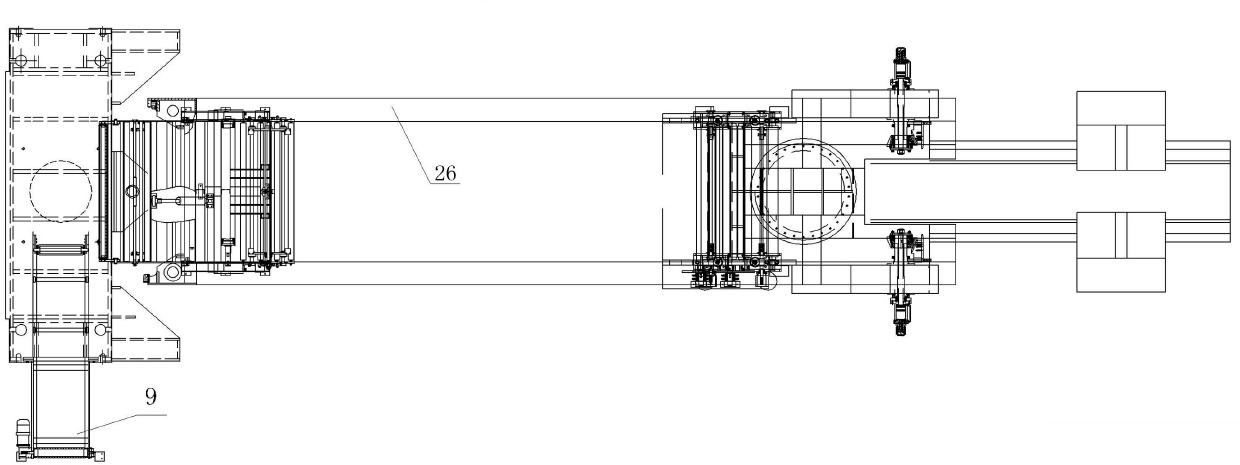

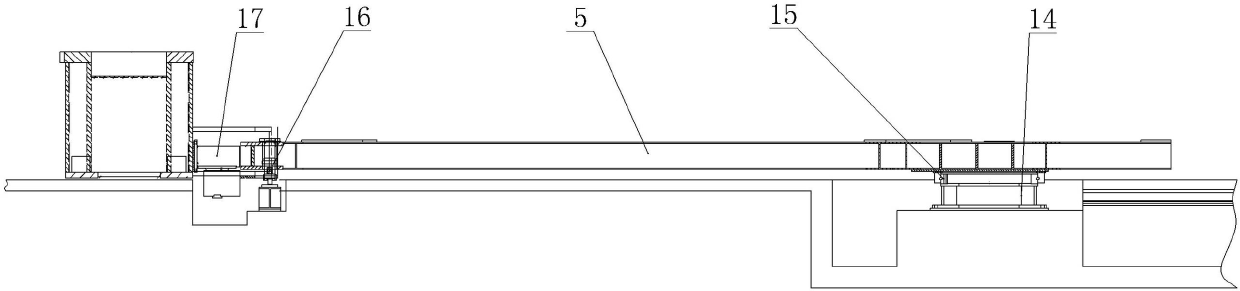

[0025] Such as figure 1 and figure 2 As shown, a schematic structural diagram of the wafer blanking production equipment of the present invention is given, which includes a feeding device 1, an uncoiler 2, a leveling machine 3, a servo feeder 4, a swing platform 5, a supporting device 6, Press machine 7, mold change system 8, palletizing system 9, waste treatment system 10, foundation 11. The shown foundation plays the role of fixing and supporting, and the swing platform 5 is rotatably arranged on the foundation 11 to realize the swing of the strip along the width direction of the foundation. The uncoiler 2 is used to support the coil material, and the leveler 3 realizes the flattening of the unrolled strip material, and the strip material is transported to the servo feeder 4 after passing through the leveling process steps. The servo feeder 4 realize

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap