Electronic element stamping raw material feeding clamping mechanical hand and clamping method thereof

A technology of electronic components and manipulators, which is applied in the field of clamping manipulators for stamping raw materials of electronic components, can solve the problems of easy falling off of workpieces, insufficient clamping force, and easy extrusion of workpieces, etc. Force area, solve vulnerable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

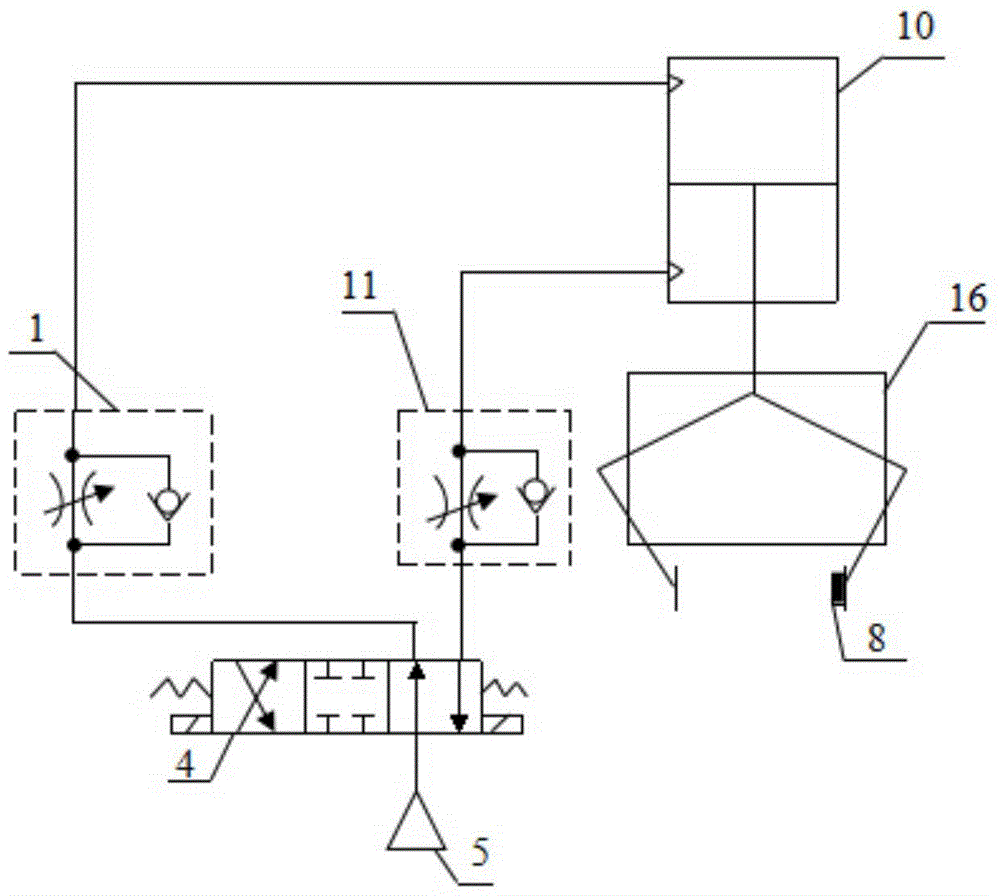

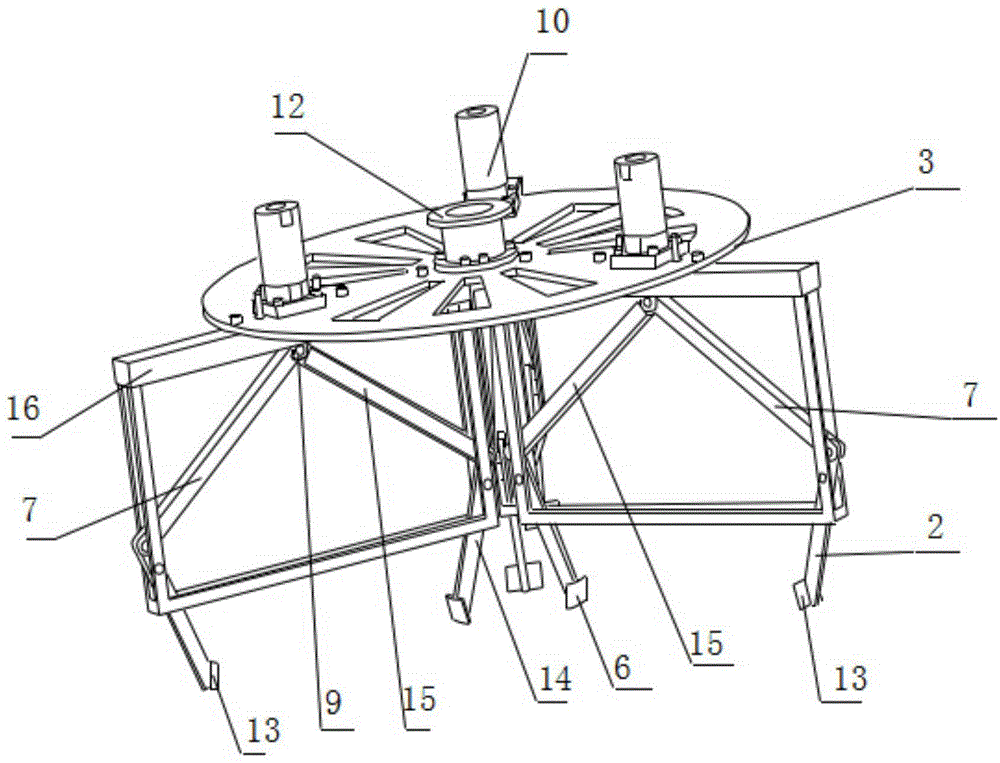

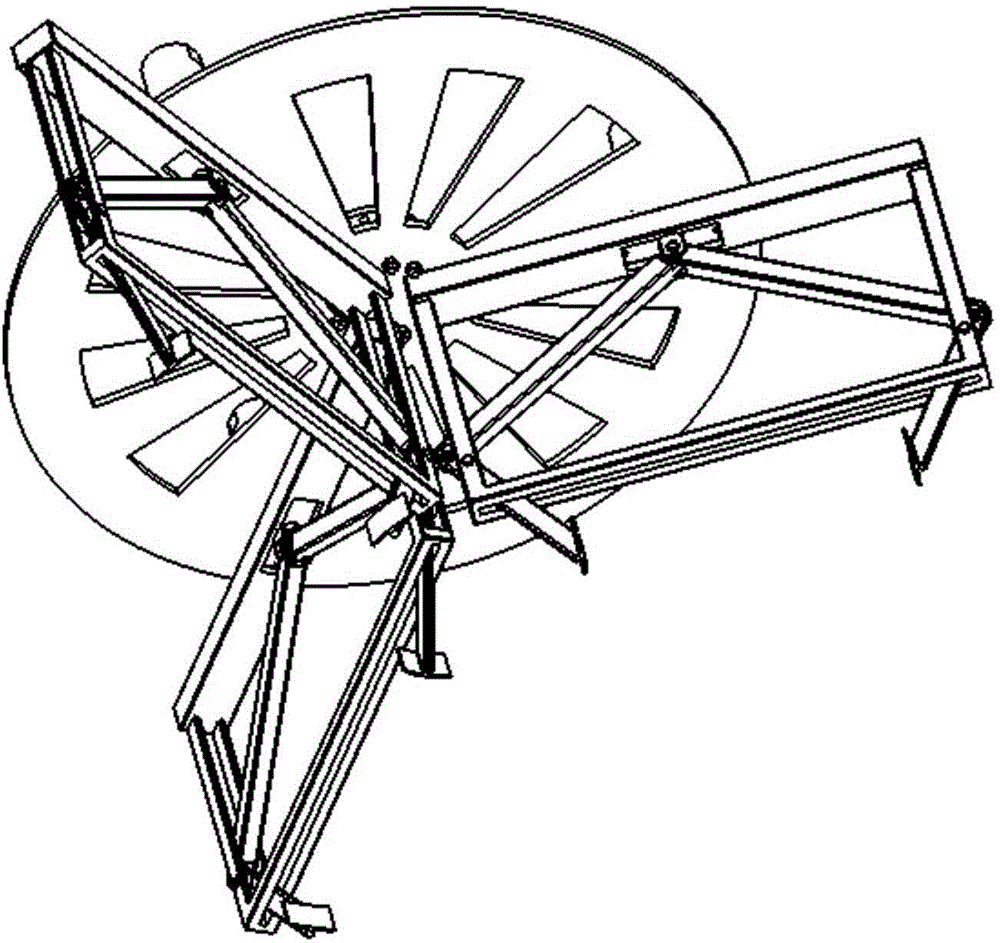

[0028] Such as Figure 1 to Figure 9 As shown, a manipulator for feeding and clamping electronic component stamping raw materials includes a mounting plate 3, and three cylinders 10 are uniformly installed on the upper end surface of the mounting plate 3, and the distances from the cylinders 10 to the axis of the mounting plate 3 are the same. The axis of the cylinder 10 is parallel to the normal line of the mounting plate 3, and the air inlet and the air outlet of the cylinder 10 are respectively connected with a throttle valve I1 and a throttle valve II11, see figure 1 , the other ends of the throttle valve I1 and the throttle valve II11 are connected with an electromagnetic reversing valve 4 , and the electromagnetic reversing valve 4 is connect

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap