Grating external cavity feedback semiconductor laser and adjusting method thereof

An external cavity feedback and semiconductor technology, which is applied in the optical field, can solve the problems of relative movement and semiconductor laser working in a stable state for a long time, and achieve the effects of easy adjustment, stable frequency and increased feedback control band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further illustrate the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

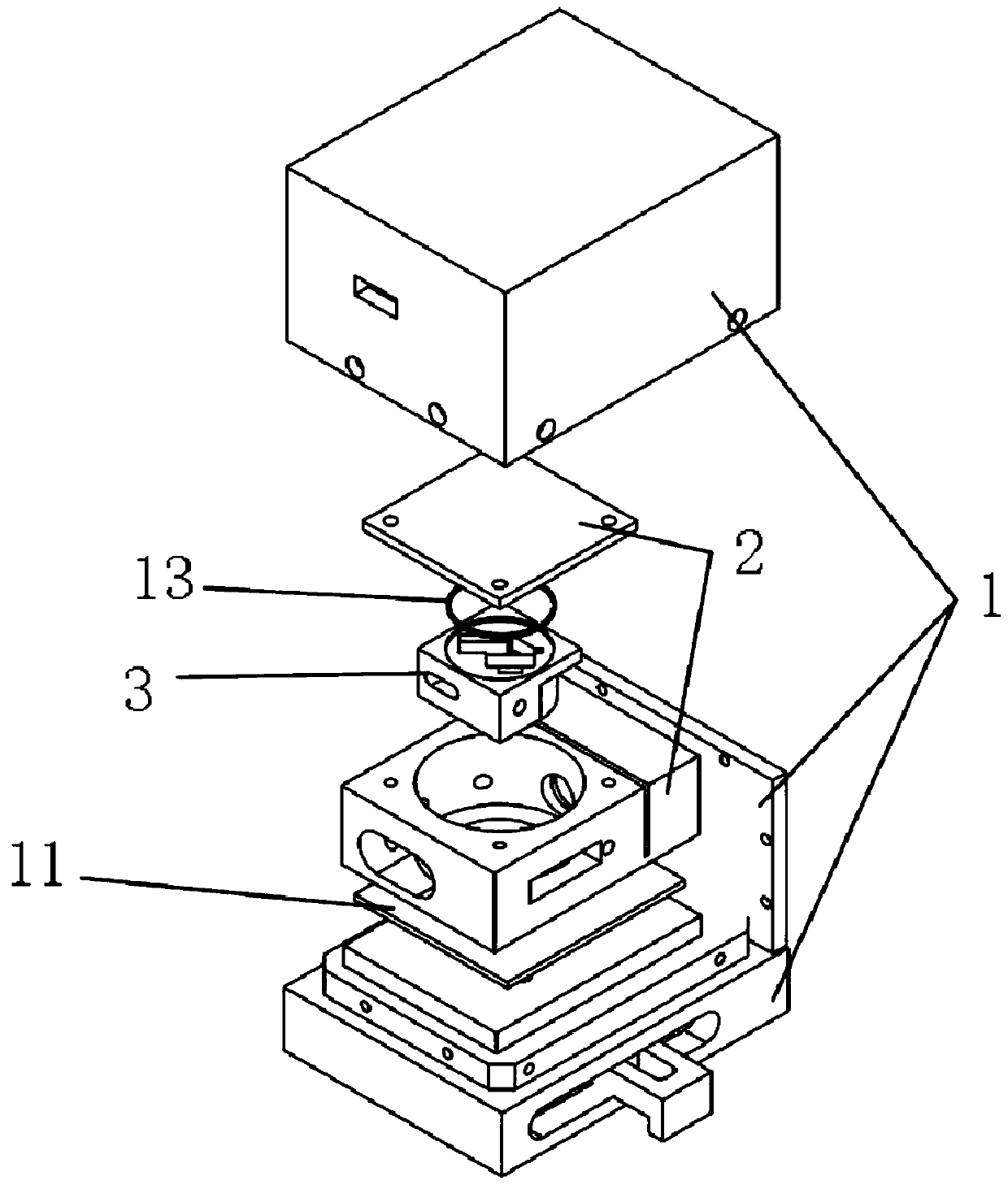

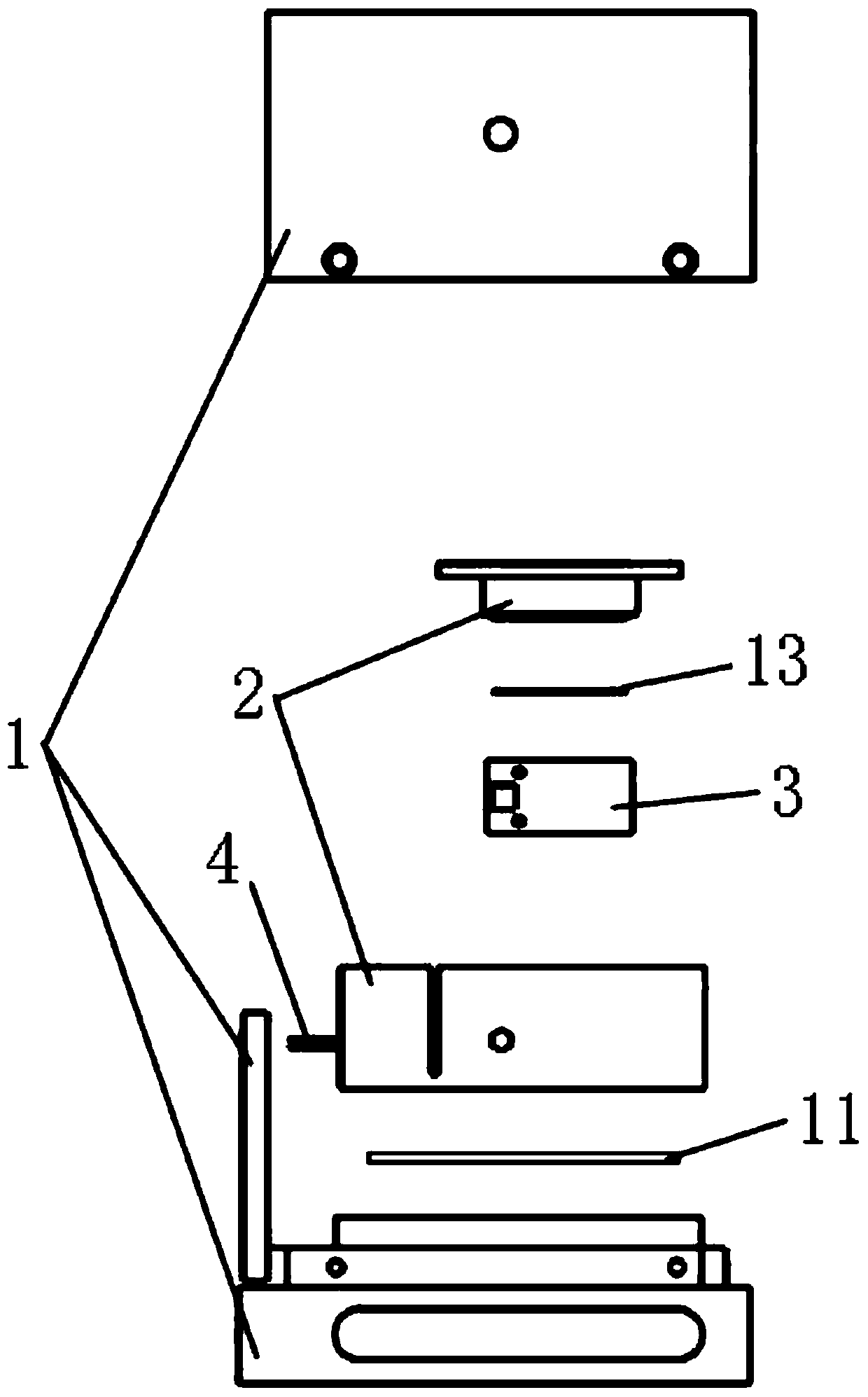

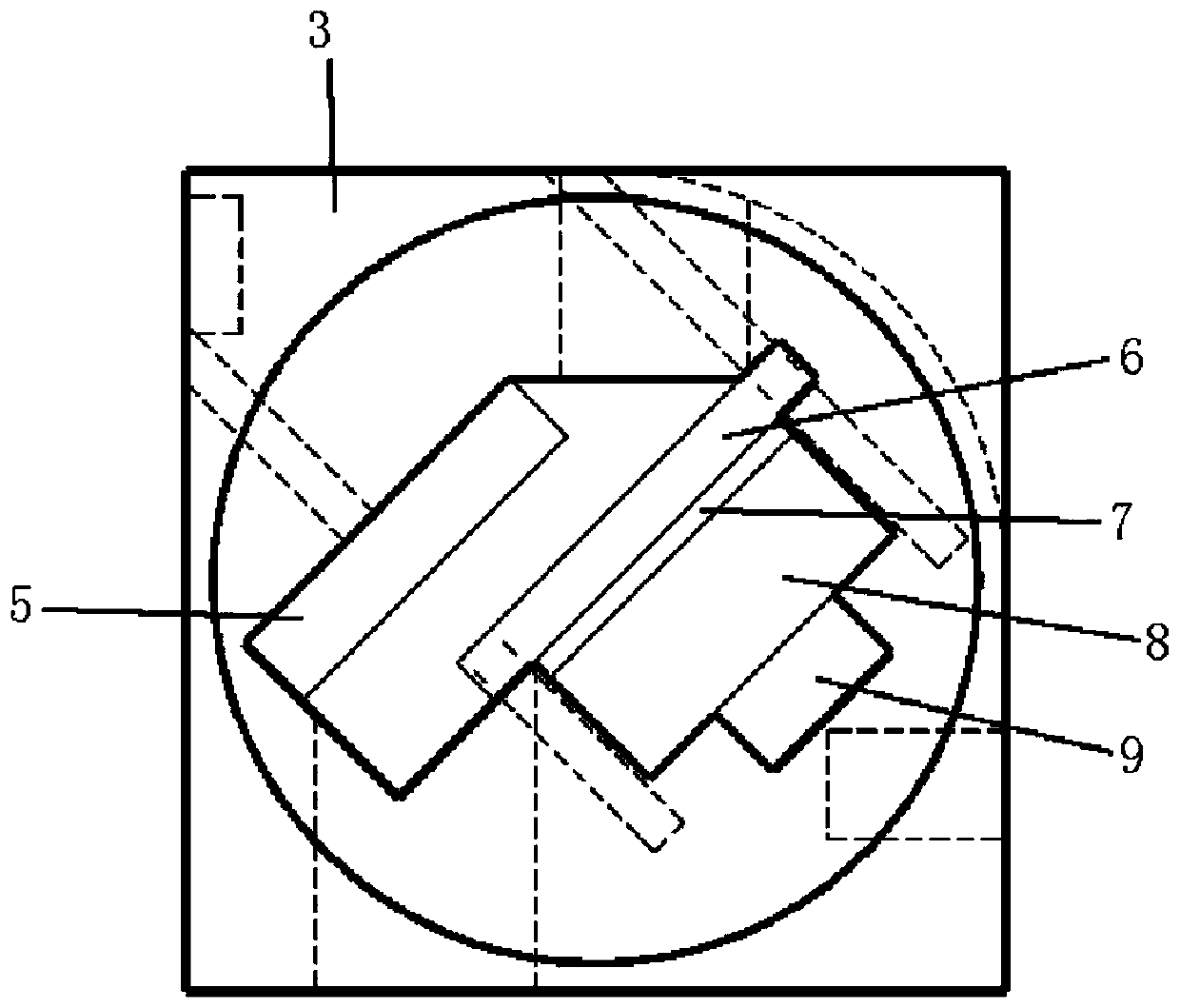

[0048] Such as Figure 1 to Figure 14 As shown, a grating external cavity feedback semiconductor laser includes a housing 1, a substrate 2, a grating frame 3, a laser diode 4, a plane mirror 5, a pressure plate 6, a backing ring 7, a feedback grating 8, a piezoelectric ceramic 9, and a Peltier 11 and gasket 13;

[0049] The housing 1 includes a side panel 101, a side cover 102 and a base 103, the side panel 101 is arranged on the rear side of the upper surface of the base 103, and a control hole 104 is provided on the side panel 101 for controlling the current The control line between the device and the laser diode 4, the control line between the temperature controller and the Peltier 11, and the control line between the high voltage discharger and the piezoelectric ceramic 9

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap