Photoelectric support frame system for automatic conveying

A technology of support system and conveying system, which is applied in the field of conveying support, can solve the problems of inability to realize free adjustment of detection points, low work efficiency, cumbersome operation process, etc., and achieve the effect of convenient daily inspection, convenient maintenance and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

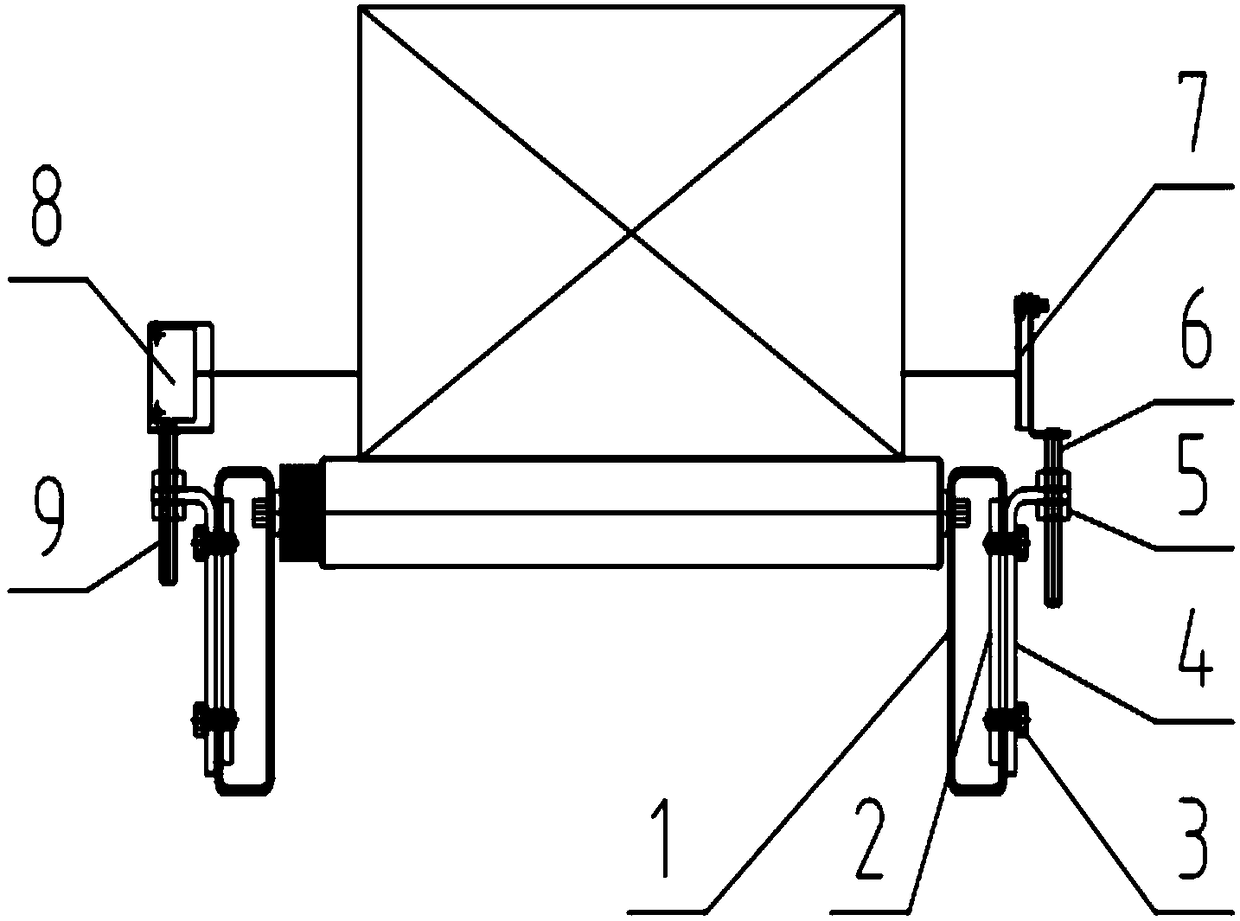

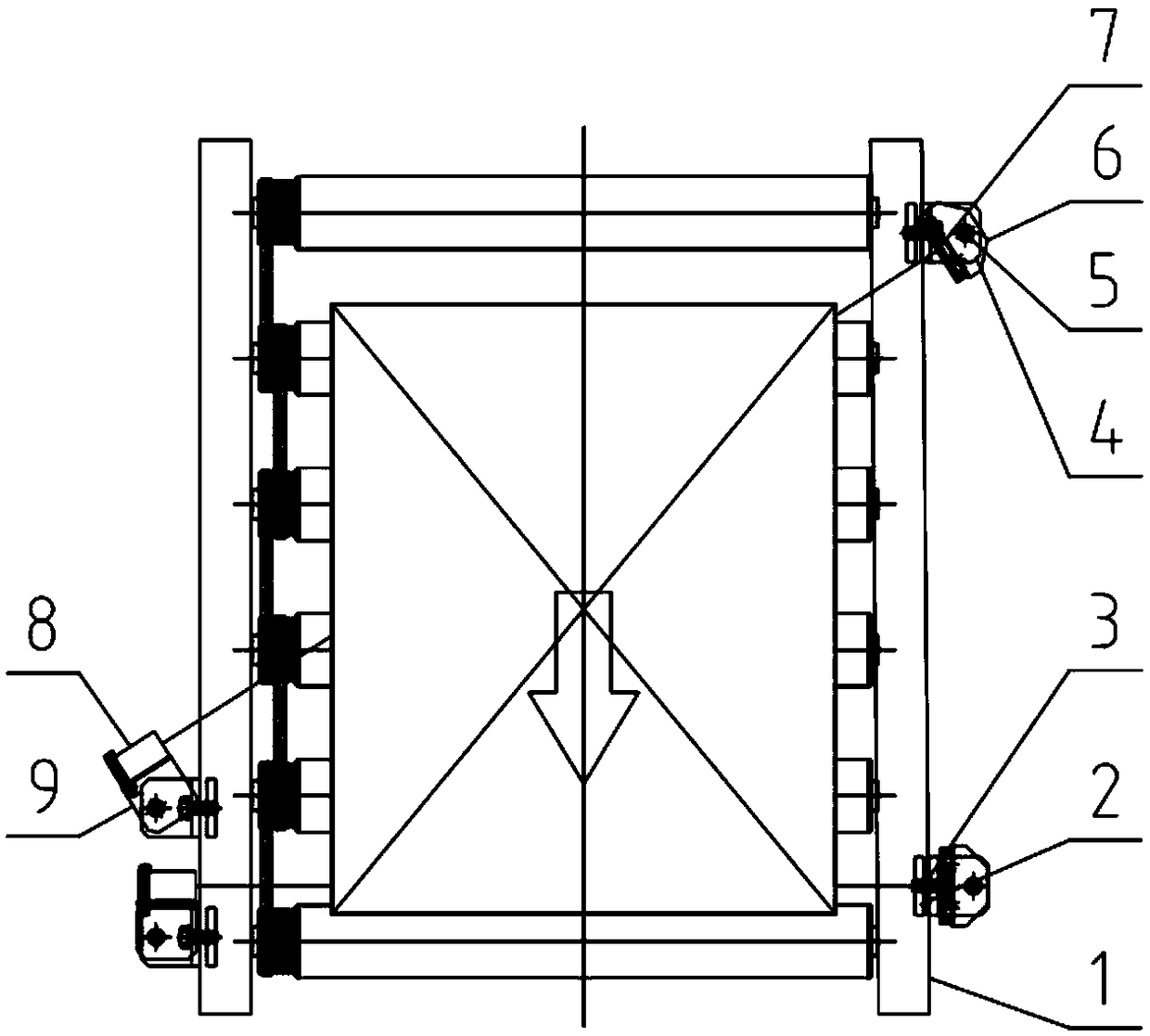

[0024] A photoelectric support system for automatic delivery, its structure is as follows Figure 1-2 As shown, it includes: a C-shaped body 1 connected to both sides of the conveying system, a splint 2 and an L-shaped splint 4 connected to the C-shaped body 1, and one or more splints can be arranged on each side of the C-shaped body , so that a greater number of other components can be connected as required. Emitting head support 9 and reflector support 6 are respectively fixed on an L-shaped splint 4 on both sides, and photoelectric emission head 8 is connected on emission head support 9, and reflector support 6 is connected with photoelectric reflector 7.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap