Front bearing box and transformation method thereof

A technology of front bearings and bearing stops, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increased occupied space, maintenance of front bearing boxes, inconvenient protection, etc., and achieves simple structure, simple and convenient processing, and easy to use The effect of less material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

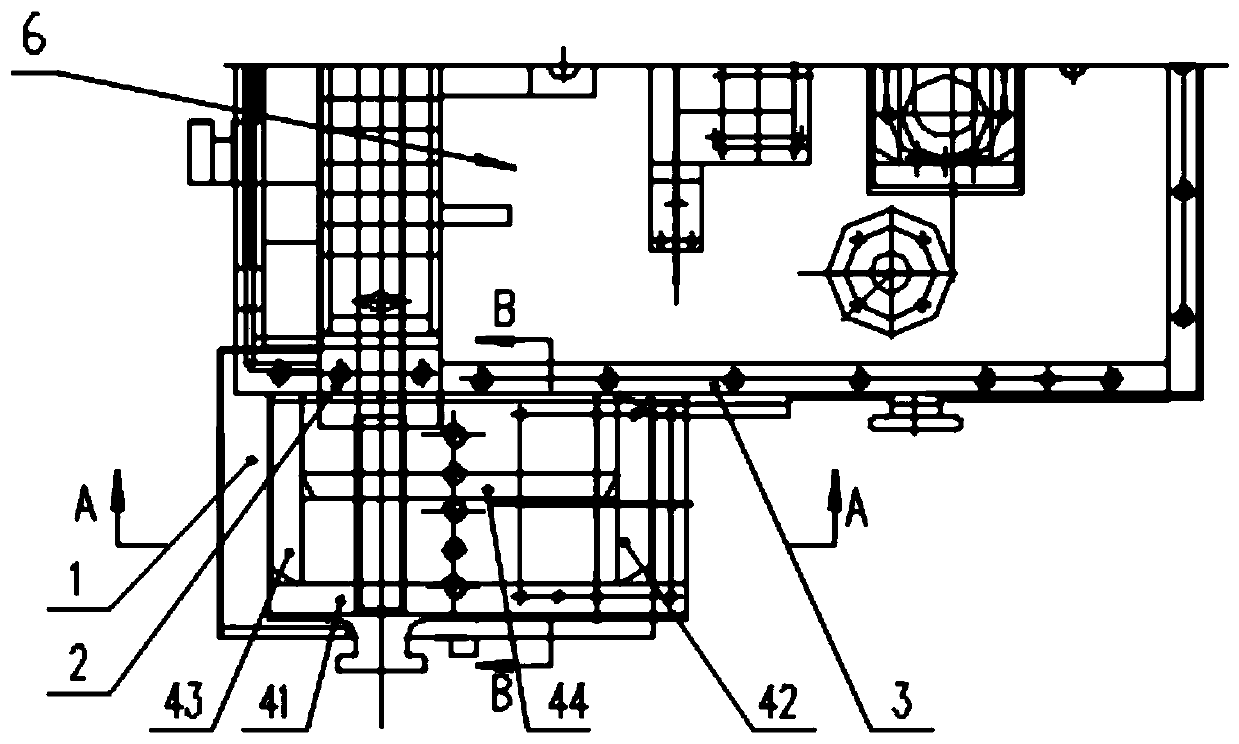

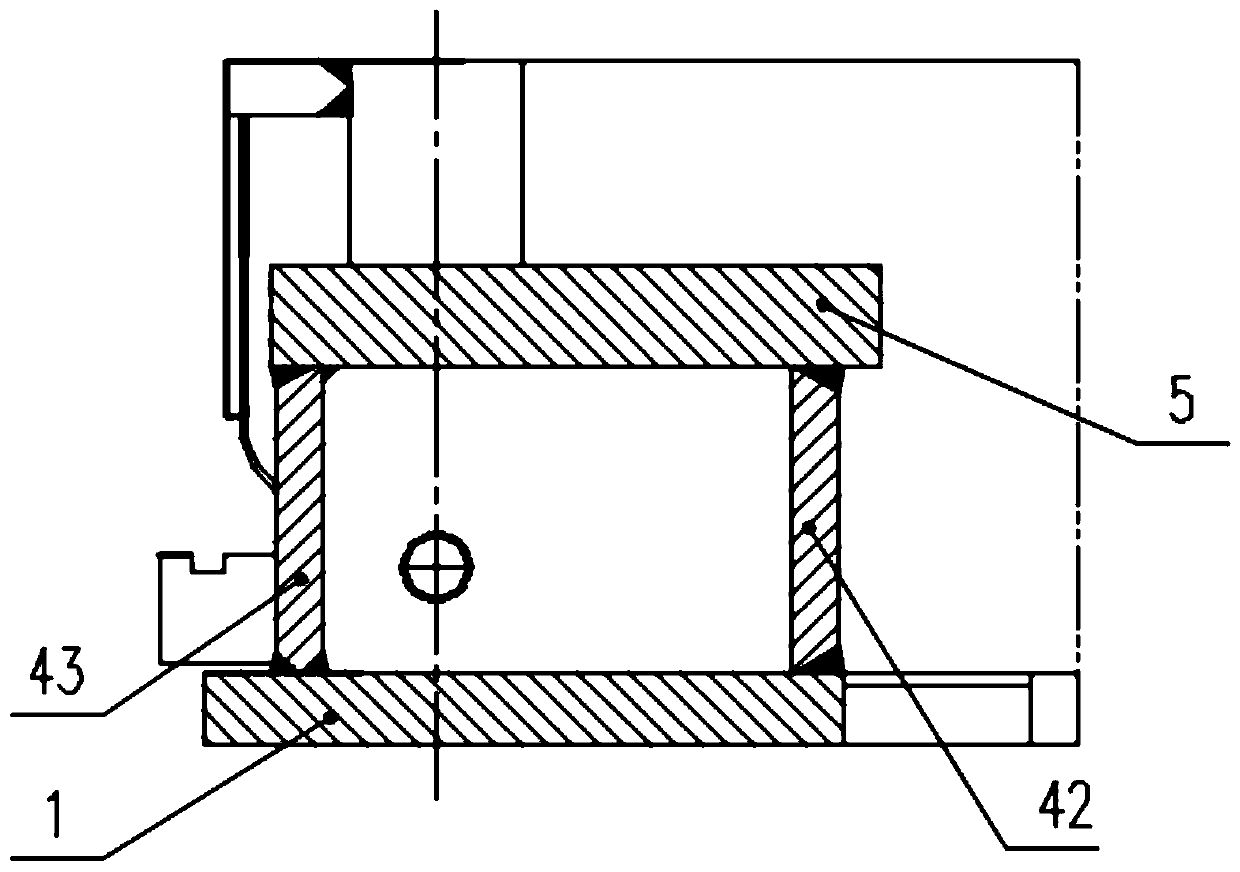

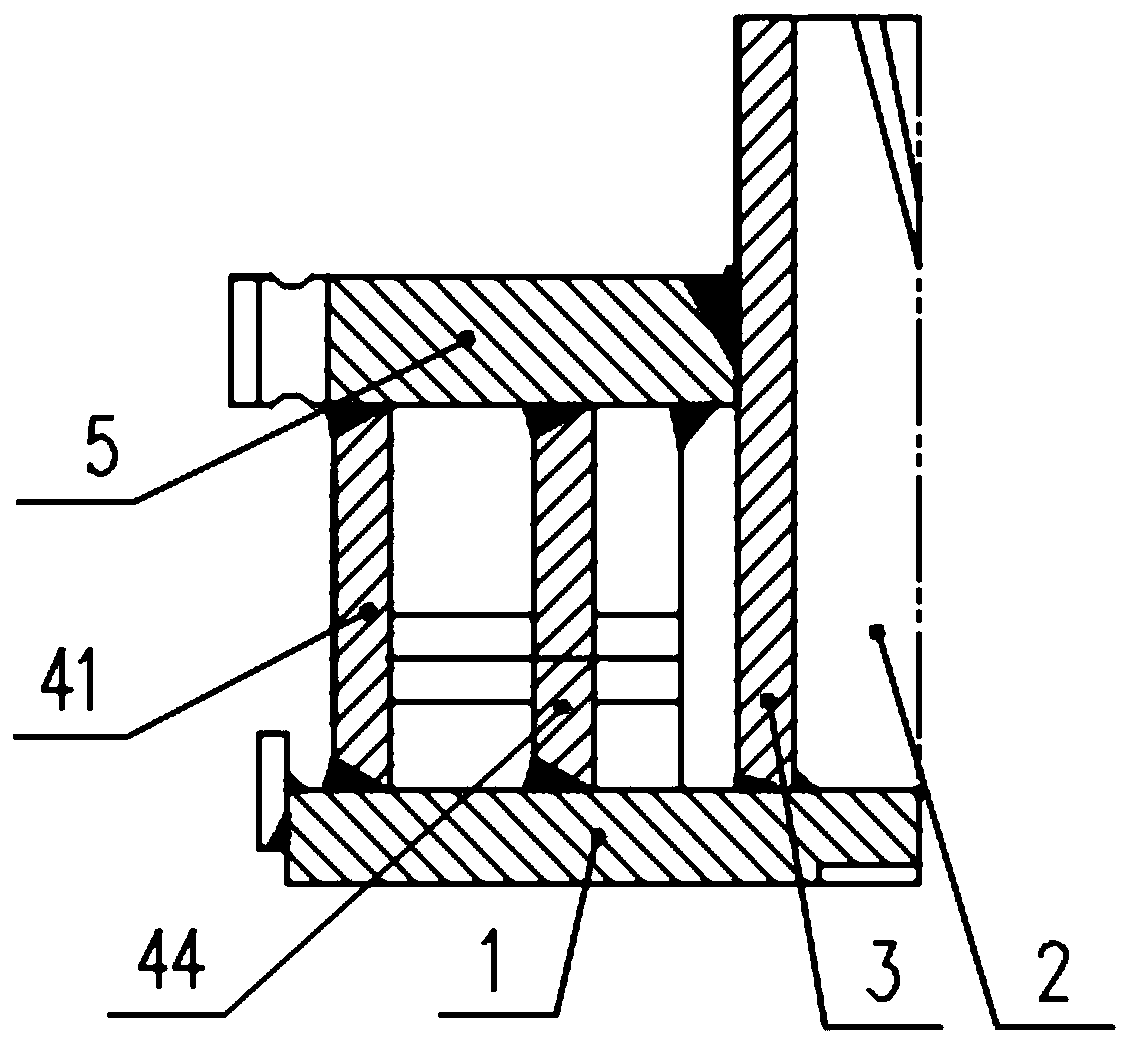

[0031] An embodiment of the present invention provides a front bearing housing, including a high-pressure oil motor and its supporting structure. The high-pressure oil motor adopts an anti-wear oil control system. The anti-wear oil control system includes an EH oil station and an anti-wear oil. The supporting structure is as follows: Figure 1~3 As shown, including the bottom plate 1 of the front bearing box, the bearing block 2 and the side plate 3 of the front bearing box, the outside of the bearing block 2 is processed with a stepped surface 21, and the specific structure of the bearing block 2 is as follows Figure 4 As shown, the support structure also includes a support vertical plate and a support horizontal plate 5, the lower end of the suppo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap