Flexible battery and preparation method thereof

A flexible battery and flexible technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc. The effect of bending the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] An embodiment of the method for preparing a flexible battery provided by the present invention, the method for preparing a flexible battery proposed by an embodiment of the present invention includes:

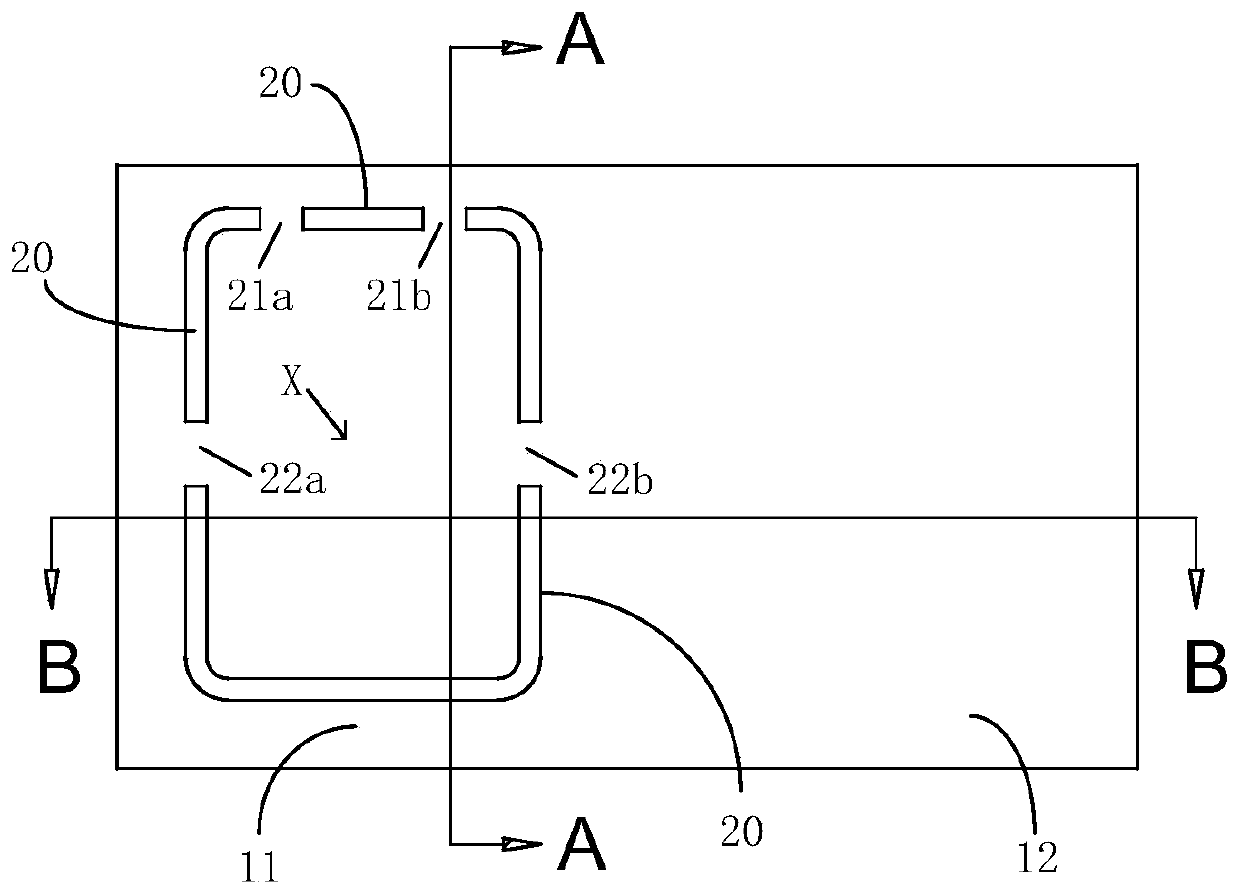

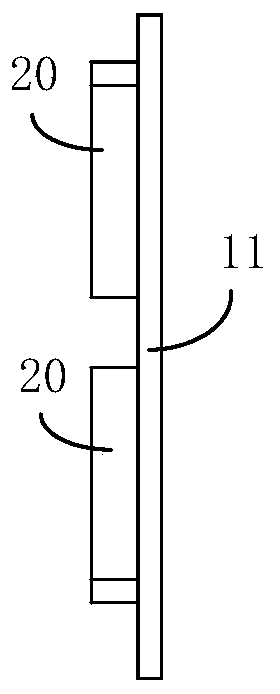

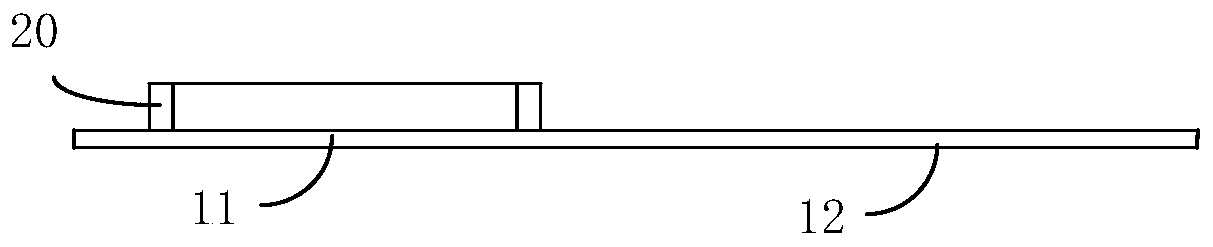

[0035] A flexible frame is arranged around the pole group fixing area on the inner surface of the first flexible film layer;

[0036] Among them, the pole group fixing area is used to set the battery pole group, the battery pole group includes a body part and an electrical connection terminal part, and the electrical connection terminal part is used as the power supply output end of the body part, usually a battery tab, and the battery tab includes a positive pole ear and negative ear.

[0037] disposing the body part of the battery pole group in the flexible frame;

[0038] The inner surface of the second flexible film layer is opposite to the inner surface of the first flexible film layer, and sealed to form a flexible wrapping film, so that the flexible wrapping film wr

Embodiment 1

[0045] The hot-melt temperature of the hot-melt adhesive is 165°C, the glue-out speed of the hot-melt adhesive is 100mm / s, the dispensing speed of the hot-melt adhesive is 400mm / s, and the hot-melt adhesive The dispensing thickness is 2mm. The test measures the peel strength between the flexible frame body and the inner surface of the first flexible film layer at 10N / in.

Embodiment 2

[0047]The hot-melt temperature of the hot-melt adhesive is 170°C, the glue-out speed of the hot-melt adhesive is 100mm / s, the dispensing speed of the hot-melt adhesive is 400mm / s, and the hot-melt adhesive The dispensing thickness is 2mm. The test measures the peel strength between the flexible frame body and the inner surface of the first flexible film layer at 15N / in.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap