Method for manufacturing LED package

A technology for light-emitting diodes and manufacturing methods, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve the problems of long hardening time, large dispersion, low light decay, etc., and achieve the effects of low cost, few consumables, and low light decay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The method for manufacturing an LED light-emitting diode package according to the present invention will be further described in detail through specific embodiments below.

[0017] A method for manufacturing an LED light-emitting diode package, as follows:

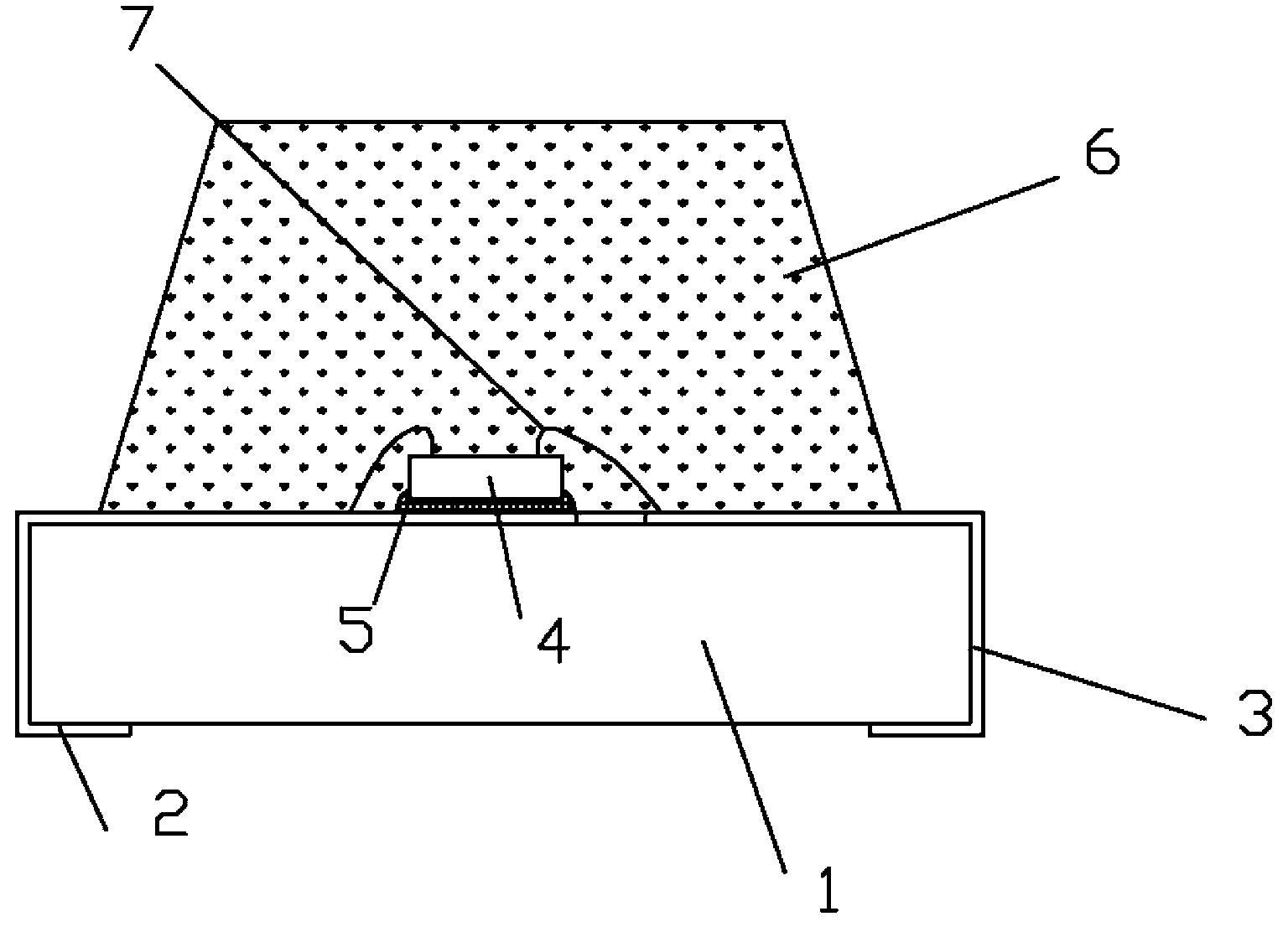

[0018] a. Install the positive electrode 2 and the negative electrode 3 on the printed circuit board 1 respectively;

[0019] b. bonding the LED chip 4 to the positive electrode 2 or the negative electrode 3 with glue, the positive pole and the negative pole of the LED chip 4 are electrically connected to the positive electrode 2 and the negative electrode 3 respectively, and the glue is hardened;

[0020] c. Place the transparent mold on the printed circuit board 1, make the LED chip 4 in the mold cavity of the transparent mold, fill the mold cavity with liquid silicone resin or a mixture of liquid silicone resin and phosphor powder, the filling is liquid silicone resin Or the mixture of liquid silicone resin and flu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap