Microstrip line Butler matrix provided with bandpass filtering characteristic and based on stub-loaded resonators

A Butler matrix and bandpass filtering technology, applied in the field of microstrip line Butler matrix, can solve the problems of circuit size increase, etc., and achieve the effects of circuit size reduction, easy design, and good isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

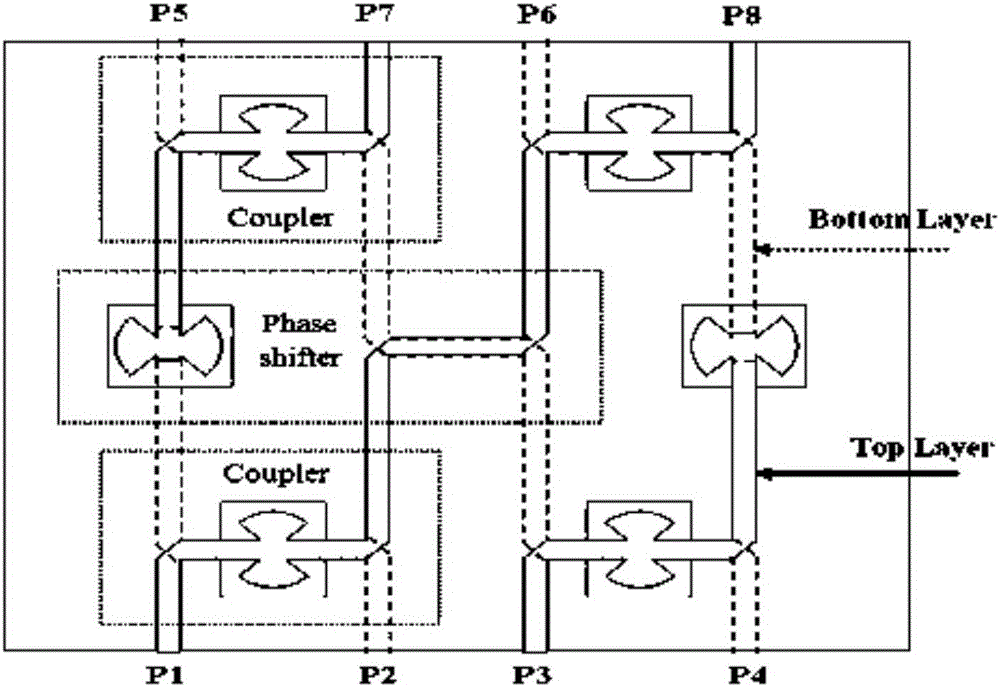

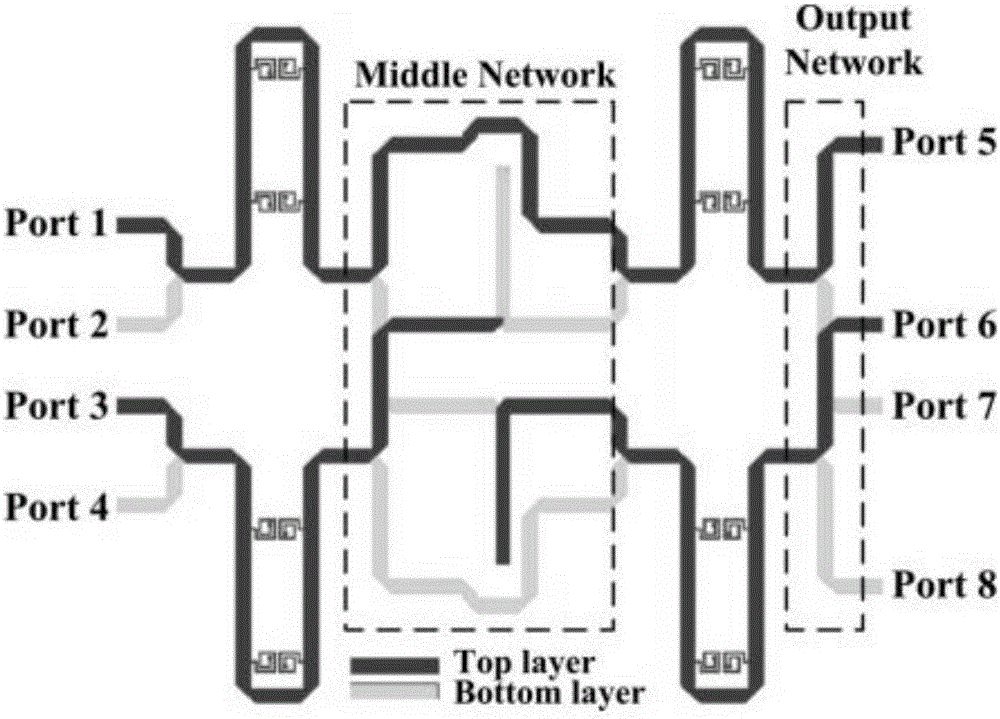

[0036] This embodiment discloses a microstrip line Butler matrix with bandpass filtering characteristics based on stub-loaded resonators such as figure 1 As shown, the microstrip line Butler matrix is fabricated on a double-sided copper-clad microstrip board 1 in the form of a printed circuit board, and the other side of the microstrip board is a copper-clad ground plane. In the structure diagram of the Butler matrix in the present invention.

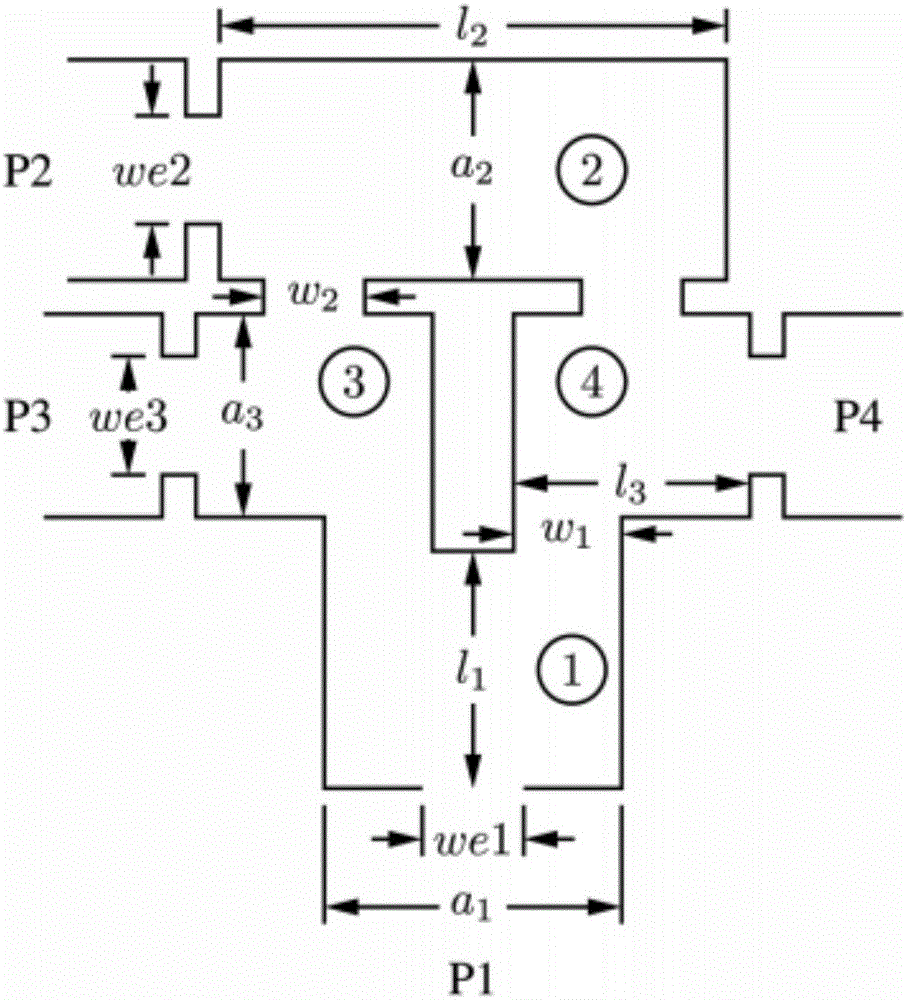

[0037]The first input terminal feeder P1 and the second input terminal P2 for inputting electromagnetic wave signals, the first output terminal feeder P3 and the second output terminal for outputting electromagnetic wave signals are respectively fabricated on the same surface of the dielectric substrate. The feeder head P4, the first port feeder 2 connected to the first input end feeder P1, the second port feeder 5 connected to the second input end feeder P2, the first output end feeder P3 The connected third port feeder 3, the fourth p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap