Vertical rotary disk type automatic indexing and welding machine for drill bits

An automatic indexing, turntable technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of uneven copper water flow, poor firmness, low efficiency, etc., to improve welding stability and welding. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

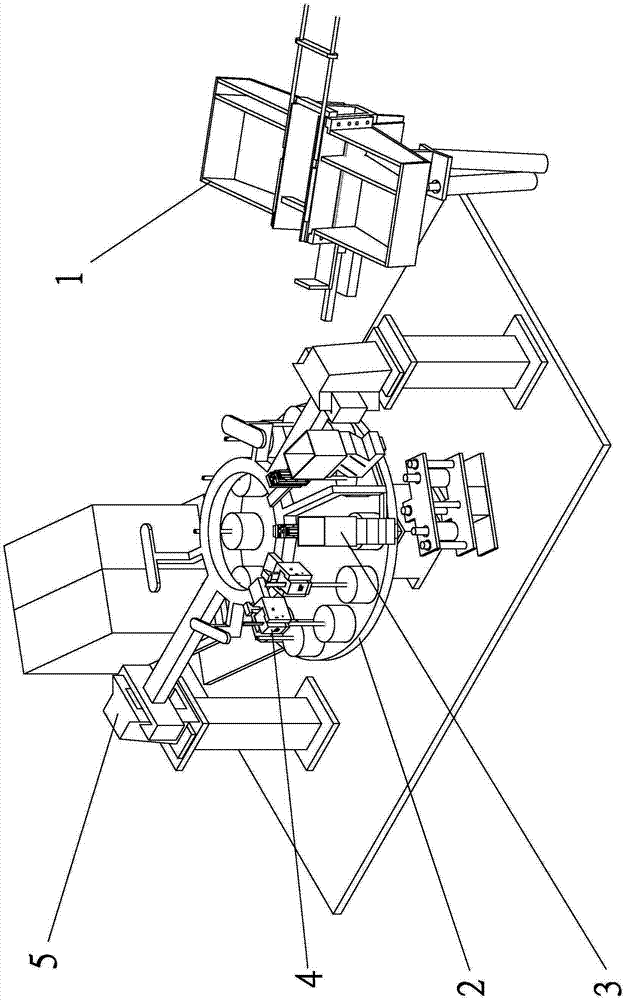

[0067] Such as figure 1 and image 3 Shown, a kind of vertical rotary table type drill bit automatic indexing welding machine provided by the present invention, it comprises:

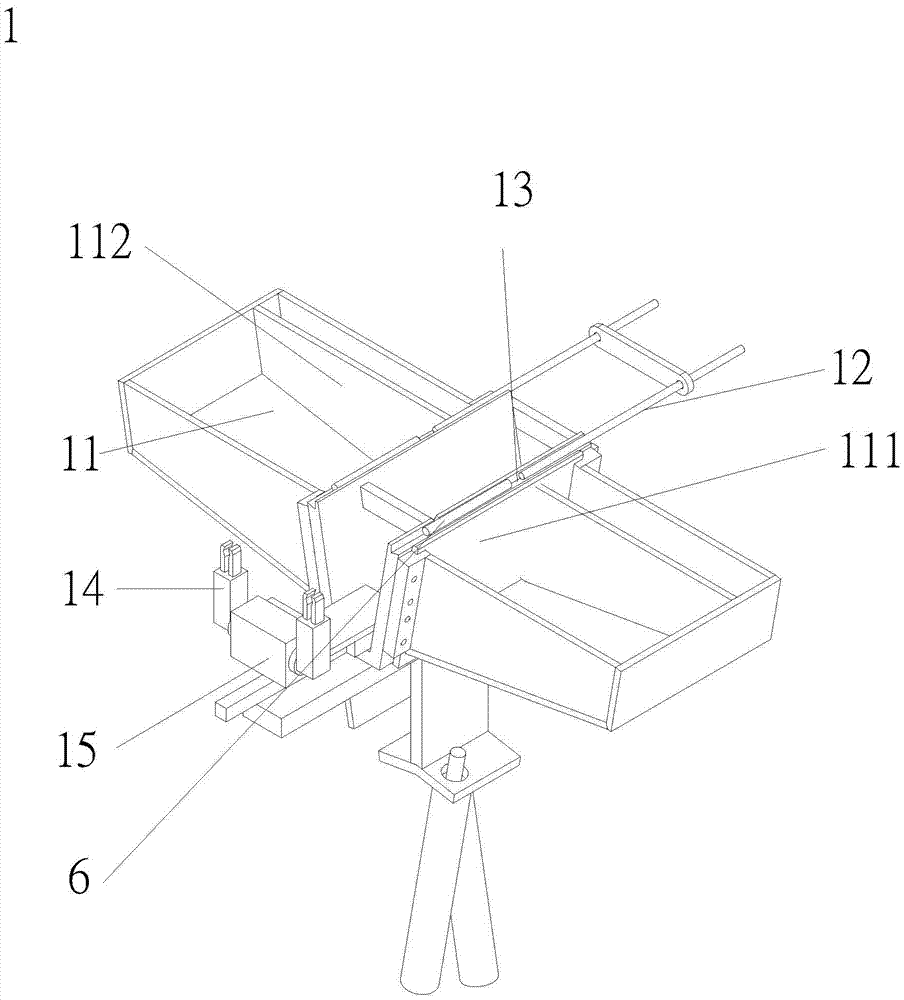

[0068] The material box type integrated conveying device 1 is used to supply the drill bit 6 to the pneumatic chuck 21 on the turntable vertical air chuck indexing device 2;

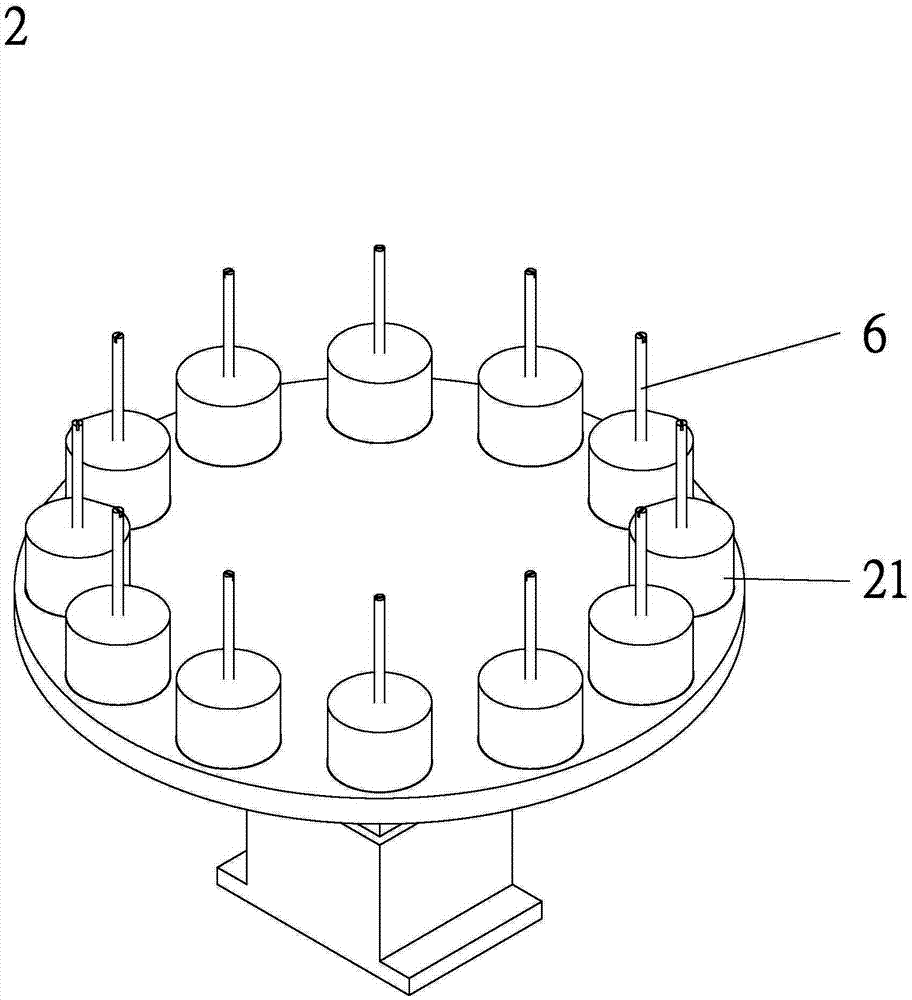

[0069] The turntable vertical air clamp indexing device 2 includes a plurality of pneumatic chucks 21 for placing the drill bit 6; at the same time, in the process of automatic welding, it cooperates with the liftable support 5 to realize the indexing of the powder feeding positioning device 3 and Adjustment and fixation of the 4 stations of the alloy welding wire cutting synchronous feeding device; the pneumatic chuck 21 is fixed on the turntable vertical air clamp indexing device 2 with a press-in structure, and the 12 pneumatic chucks 21 are clamped The structure is composed of elastic pressure and buckle return air, that is, th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap