Silicon carbide ceramic wave-absorbing pyramid based on 3D printing and preparation method thereof

A silicon carbide ceramic, 3D printing technology, applied in ceramic molding machines, manufacturing tools, additive processing, etc., can solve problems such as inability to meet test requirements, and achieve the effect of saving sintering costs, diversifying shape and structure, and high development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

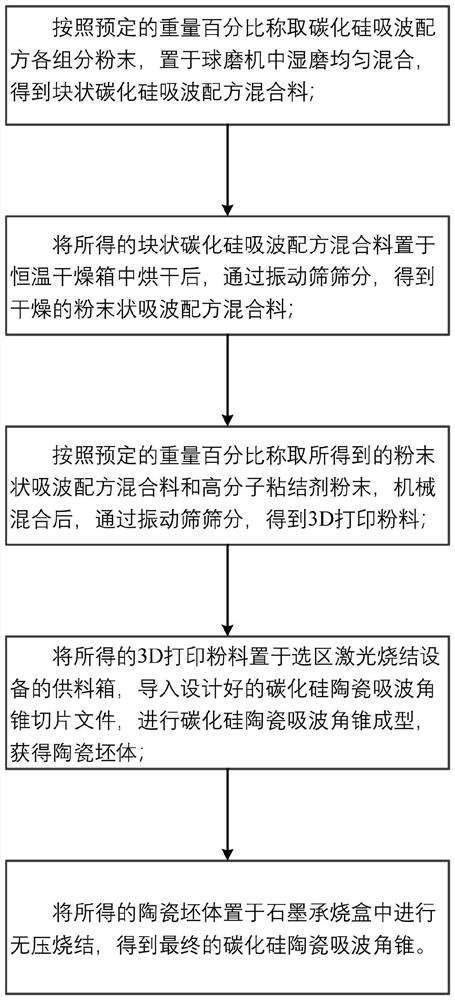

Method used

Image

Examples

Embodiment 1

[0034] Example 1: The silicon carbide ceramic wave-absorbing pyramid includes a silicon carbide wave-absorbing mixed powder and a polymer binder, and the silicon carbide wave-absorbing mixed powder includes: SiC 25% to 45%, BaTiO 3 4%~9%, MnO 2 2%~6%, MgO 1%~3%, Al 2 o 3 2%~6%, Y 2 o 3 2% to 6%, and the remaining ingredients are polymer binders.

Embodiment 2

[0035] Embodiment 2: The silicon carbide ceramic wave-absorbing pyramid includes silicon carbide wave-absorbing mixed powder and polymer binder, and the silicon carbide wave-absorbing mixed powder includes: SiC 25%, BaTiO 3 4%, MnO 2 2%, MgO 1%, Al 2 o 3 2%, Y 2 o 3 2%, and the remaining ingredients are polymer binders.

Embodiment 3

[0036]Embodiment 3: The silicon carbide ceramic wave-absorbing pyramid includes silicon carbide wave-absorbing mixed powder and polymer binder, and the silicon carbide wave-absorbing mixed powder includes: SiC 45%, BaTiO 3 9%, MnO 2 6%, MgO 3%, Al 2 o 3 6%, Y 2 o 3 6%, and the remaining ingredients are polymer binders.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap