Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2 results about "Crystal transformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crystal form G of ibrutinib and preparation method

InactiveCN105646499AImprove stabilityHigh purityOrganic active ingredientsOrganic chemistry methodsSolubilitySolvent

The invention discloses a crystal form G of ibrutinib. The crystal form G is characterized in that X-ray powder diffraction (X-RPD) which adopts Cu-Kalpha radiation and is represented with a 2theta angle has diffraction peaks in positions at angles of 5.0 degrees plus or minus 0.2 degrees, 7.3 degrees plus or minus 0.2 degrees, 10.1 degrees plus or minus 0.2 degrees, 12.0 degrees plus or minus 0.2 degrees, 13.2 degrees plus or minus 0.2 degrees, 17.1 degrees plus or minus 0.2 degrees, 19.5 degrees plus or minus 0.2 degrees, 20.8 degrees plus or minus 0.2 degrees, 22.3 degrees plus or minus 0.2 degrees, 24.3 degrees plus or minus 0.2 degrees, 27.4 degrees plus or minus 0.2 degrees and 31.2 degrees plus or minus 0.2 degrees. Related solvents in a preparation process of the crystal form G are cheap, the conditions are mild, the operation is simple, good controllability and reproducibility are realized, further, the prepared crystal form has great stability, the HPLC (high performance liquid chromatography) purity is higher than 99%, and the phenomenon of crystal transformation can be avoided; besides, the solubility is high, the dissolubility is good, and the bioavailability is high.

Owner:孙霖

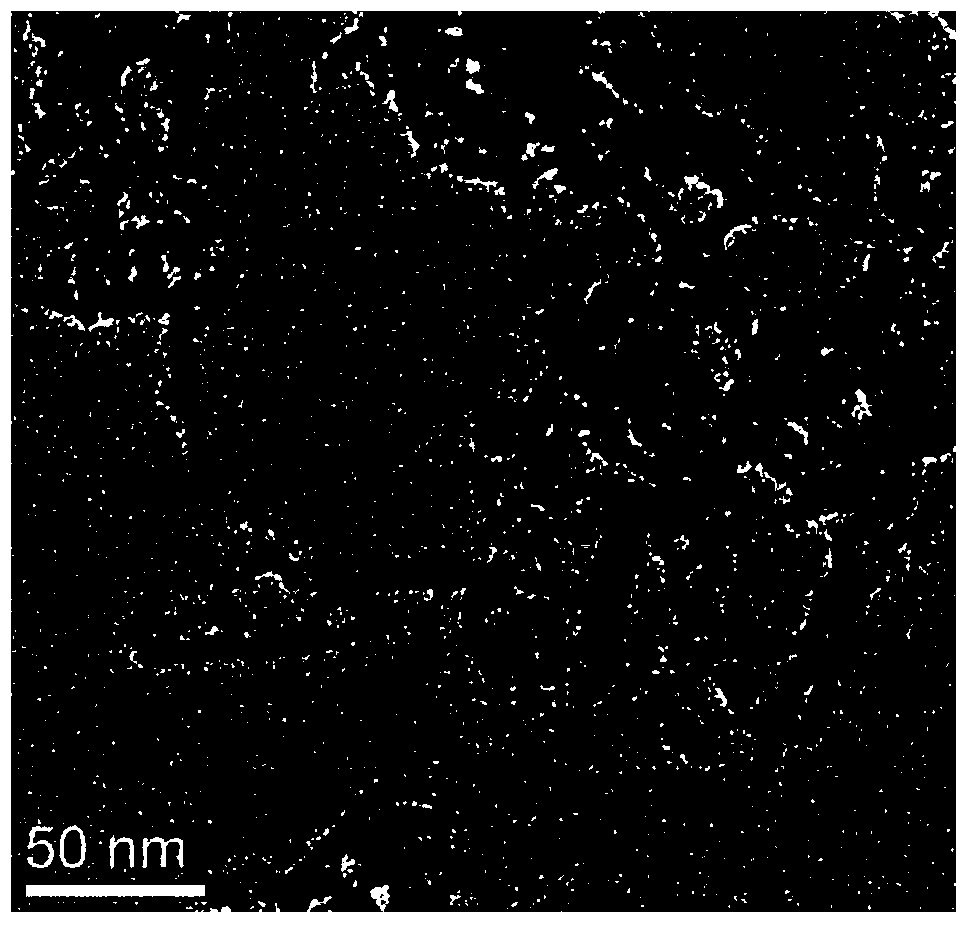

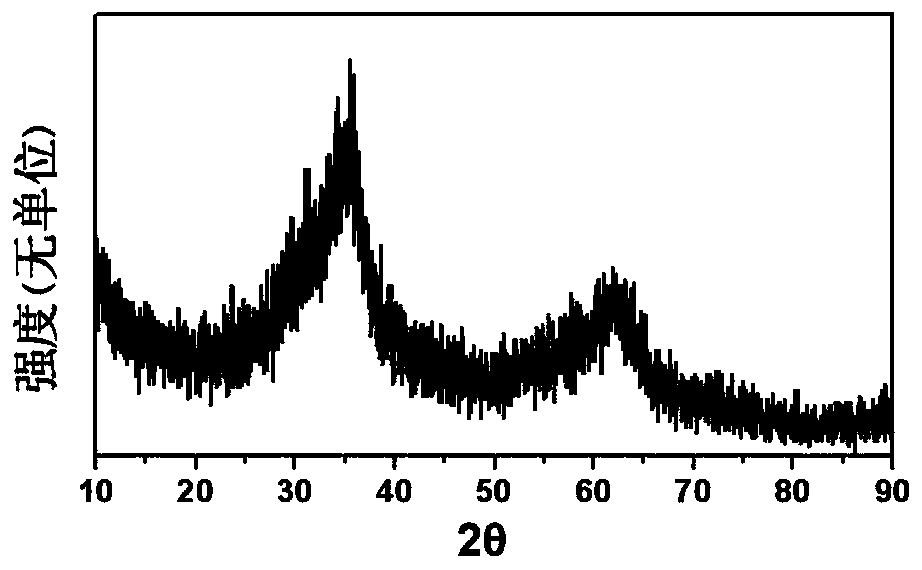

Preparation method of nano ferric oxide (Fe2O3) for acetone gas sensor material

The invention relates to a preparation method of nano ferric oxide (Fe2O3) for an acetone gas sensor material. A pre-synthesized ordered mesoporous silicon oxide material is used as a hard template, and a nano Fe2O3 material is prepared by the steps of iron precursor impregnation, drying, calcination crystal transformation, template removal and the like. The nano Fe2O3 prepared by the hard template process is used as a gas sensitive material to prepare slurry which is coated on a sensing layer at a thickness of 0.2-50 microns; through the preparation method of the nano-structure gas sensitive material, a gas sensitive layer with a large specific surface area is realized, and the gas sensitivity is relatively high. The preparation method of a gas sensor is simple to operate and easy to realize, and the gas-sensitive specific surface area is larger than 180m<2> / g; moreover, the acetone gas sensitivity of the prepared gas sensor is improved to 100ppm, and the best sensing property is greater than 10, which is higher than the property of an industrial commonly-used acetone sensor.

Owner:TIANJIN UNIV

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap