Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Diffraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diffraction refers to various phenomena that occur when a wave encounters an obstacle or a slit. It is defined as the bending of waves around the corners of an obstacle or through an aperture into the region of geometrical shadow of the obstacle/aperture. The diffracting object or aperture effectively becomes a secondary source of the propagating wave. Italian scientist Francesco Maria Grimaldi coined the word "diffraction" and was the first to record accurate observations of the phenomenon in 1660.

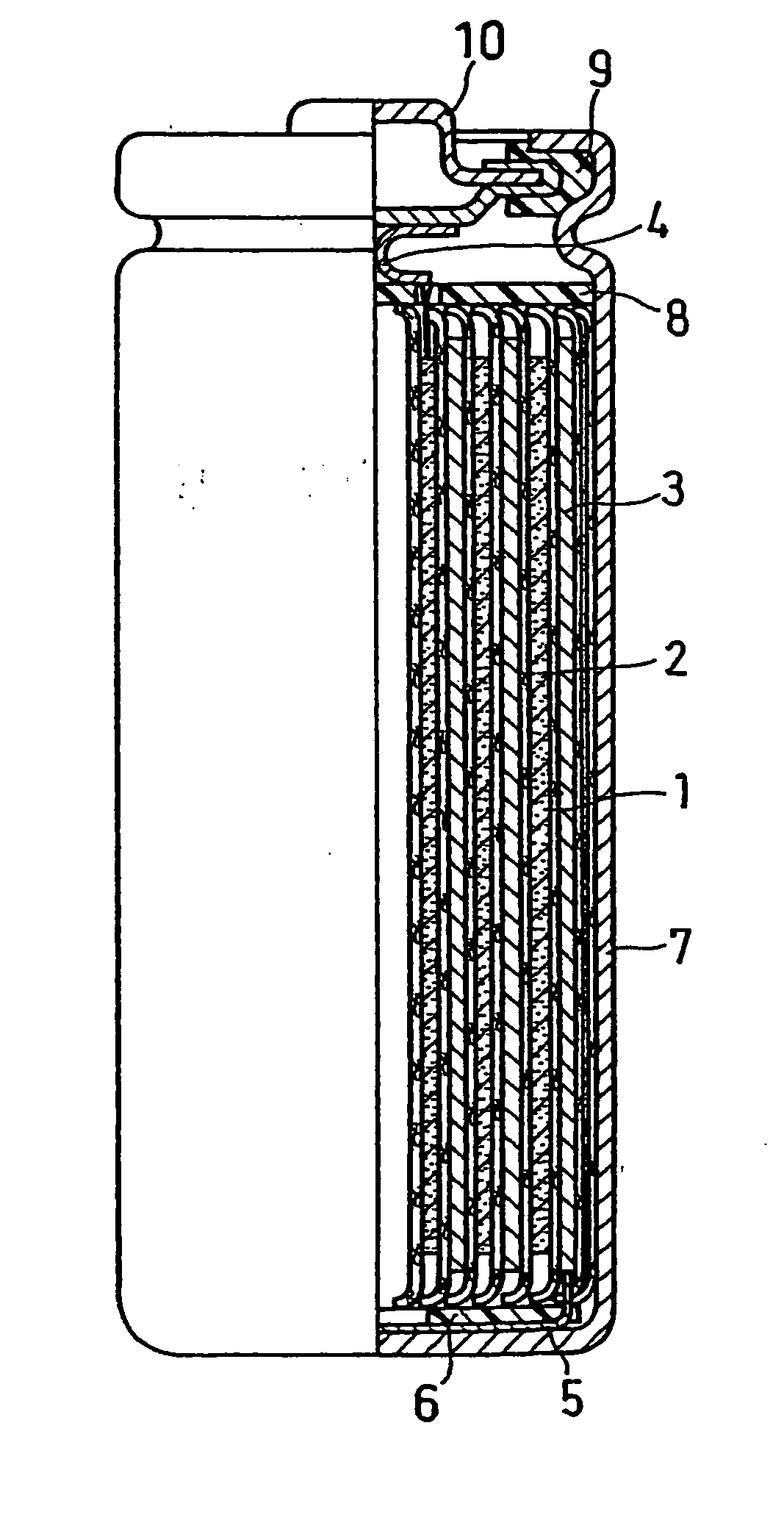

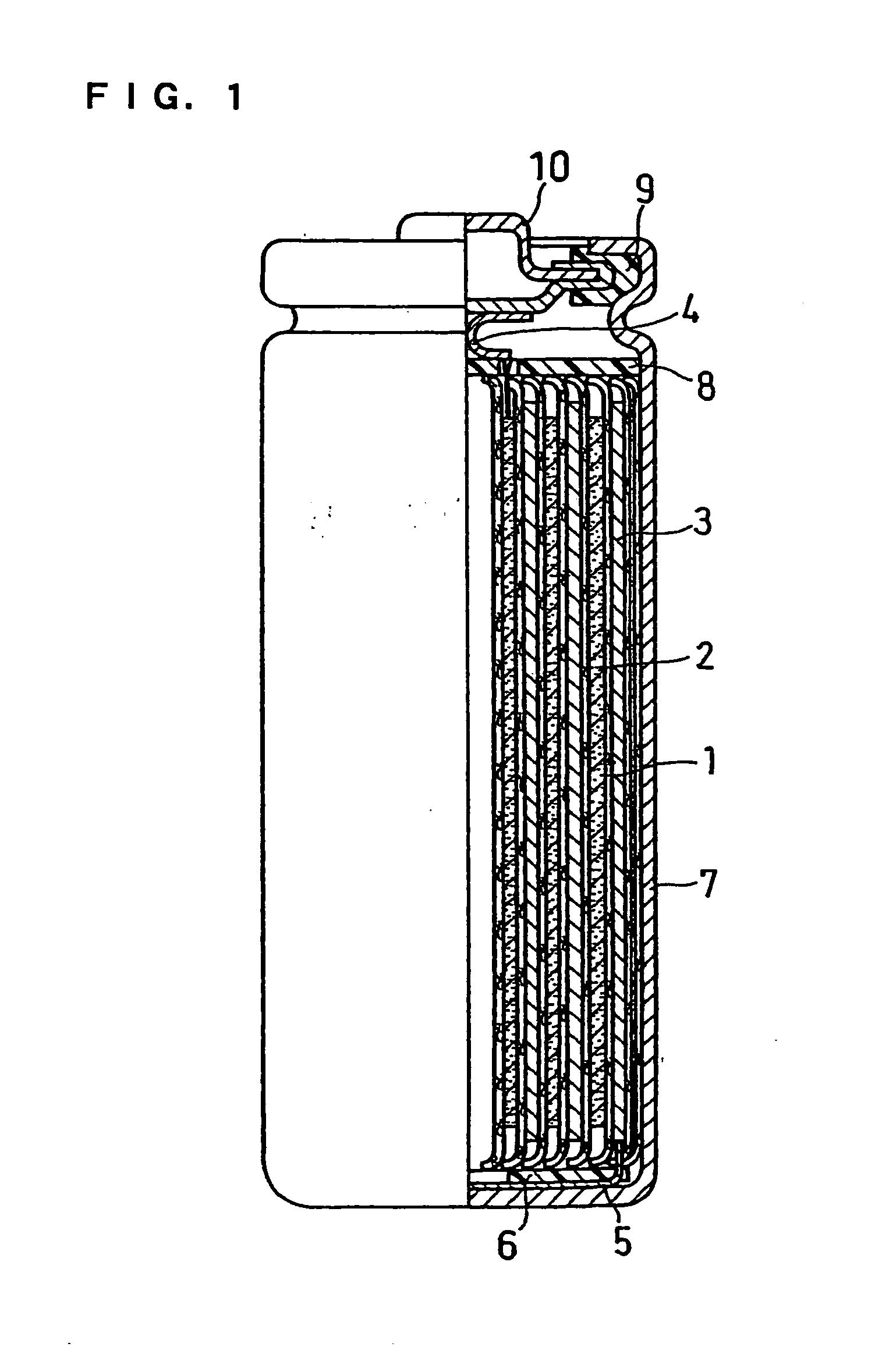

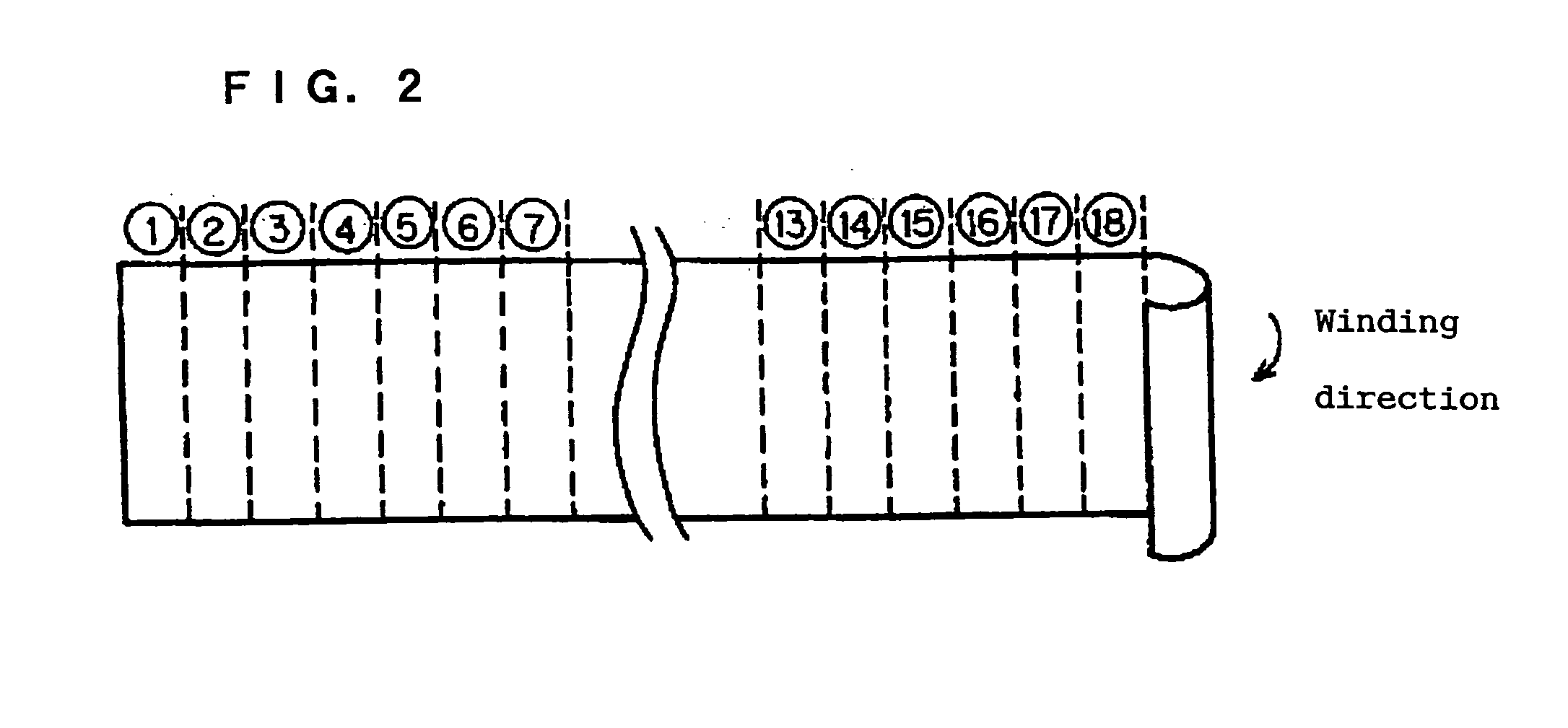

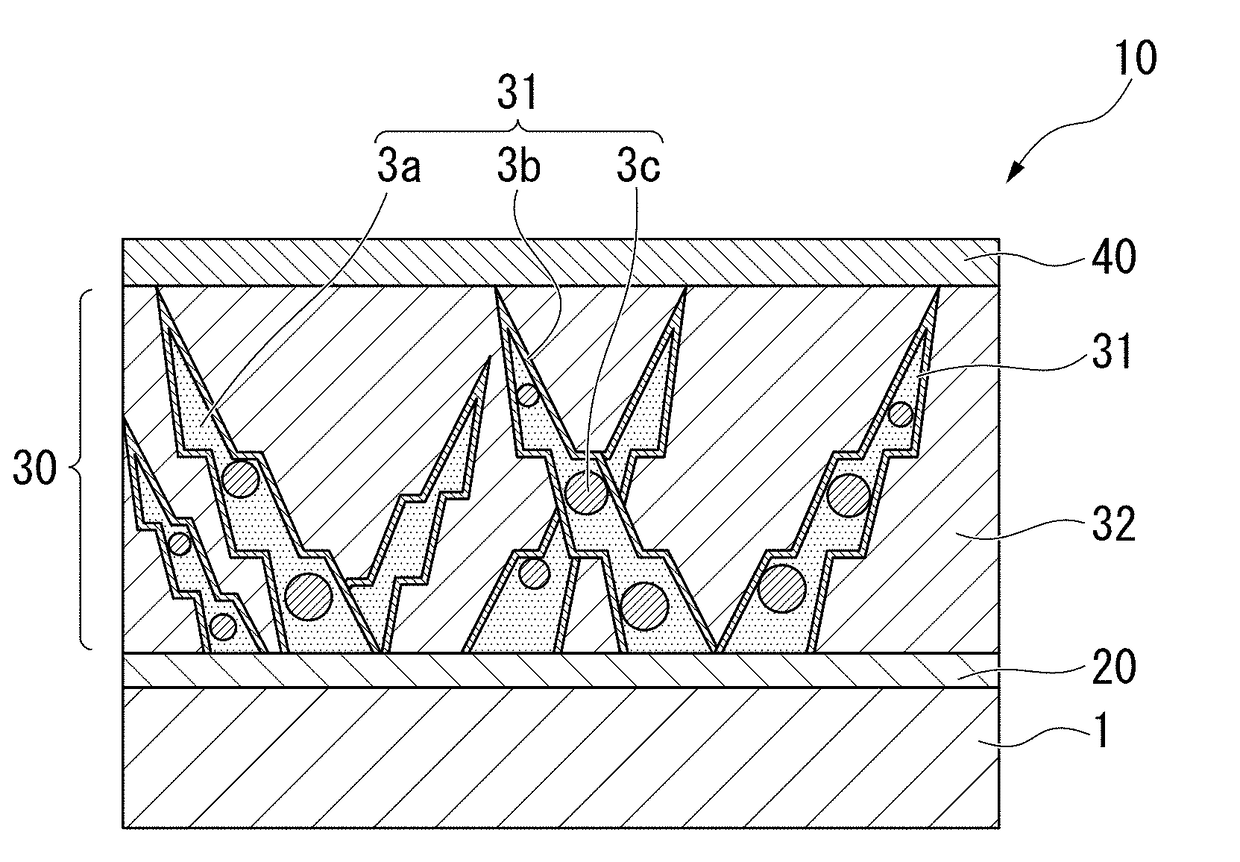

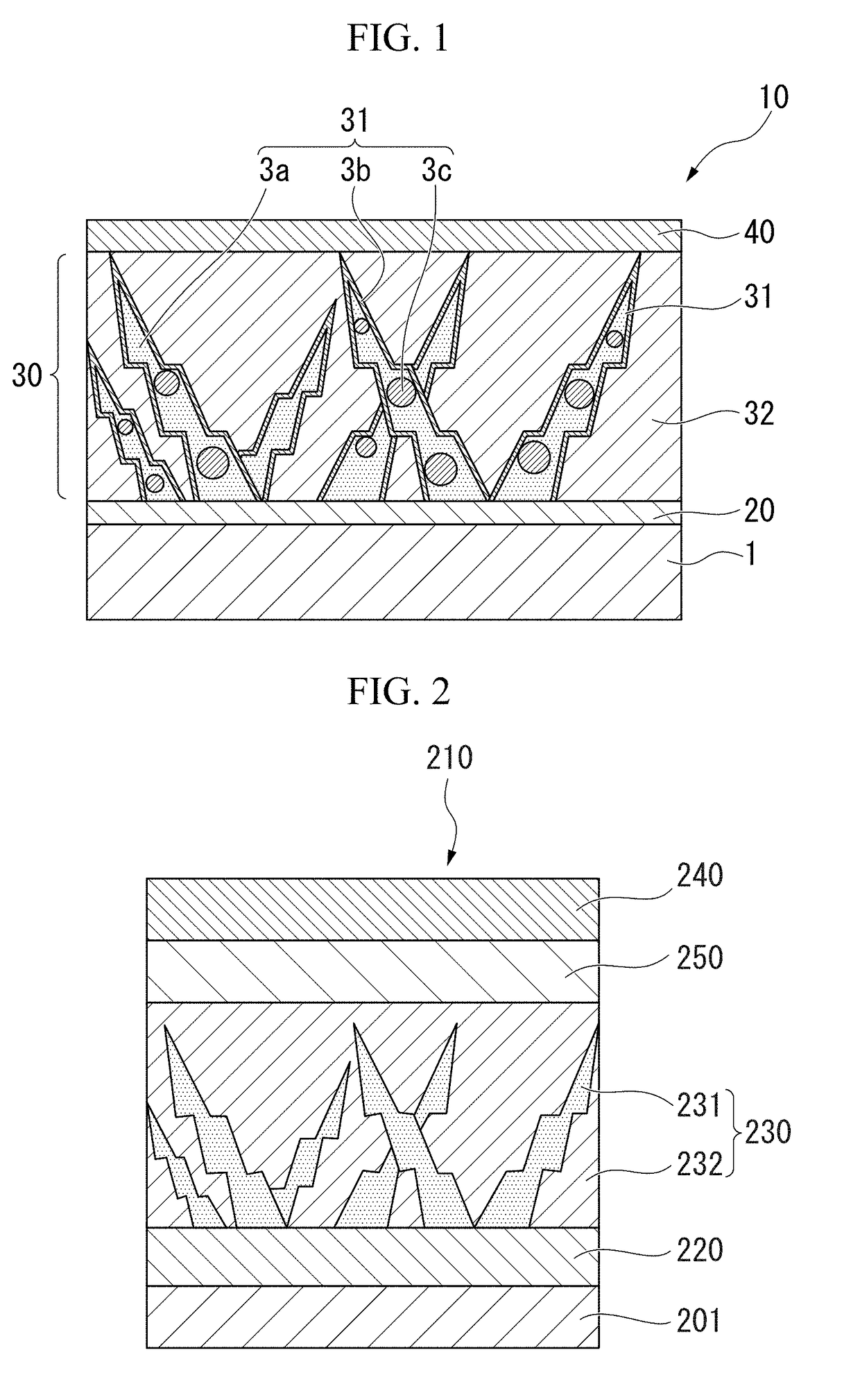

Negative electrode current collector, negative electrode using the same, and non aqueous electrolytic secondary cell

ActiveUS20040072079A1Improve featuresHigh strengthNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsX-rayMaterials science

Owner:PANASONIC CORP

Crystal form G of ibrutinib and preparation method

InactiveCN105646499AImprove stabilityHigh purityOrganic active ingredientsOrganic chemistry methodsSolubilitySolvent

The invention discloses a crystal form G of ibrutinib. The crystal form G is characterized in that X-ray powder diffraction (X-RPD) which adopts Cu-Kalpha radiation and is represented with a 2theta angle has diffraction peaks in positions at angles of 5.0 degrees plus or minus 0.2 degrees, 7.3 degrees plus or minus 0.2 degrees, 10.1 degrees plus or minus 0.2 degrees, 12.0 degrees plus or minus 0.2 degrees, 13.2 degrees plus or minus 0.2 degrees, 17.1 degrees plus or minus 0.2 degrees, 19.5 degrees plus or minus 0.2 degrees, 20.8 degrees plus or minus 0.2 degrees, 22.3 degrees plus or minus 0.2 degrees, 24.3 degrees plus or minus 0.2 degrees, 27.4 degrees plus or minus 0.2 degrees and 31.2 degrees plus or minus 0.2 degrees. Related solvents in a preparation process of the crystal form G are cheap, the conditions are mild, the operation is simple, good controllability and reproducibility are realized, further, the prepared crystal form has great stability, the HPLC (high performance liquid chromatography) purity is higher than 99%, and the phenomenon of crystal transformation can be avoided; besides, the solubility is high, the dissolubility is good, and the bioavailability is high.

Owner:孙霖

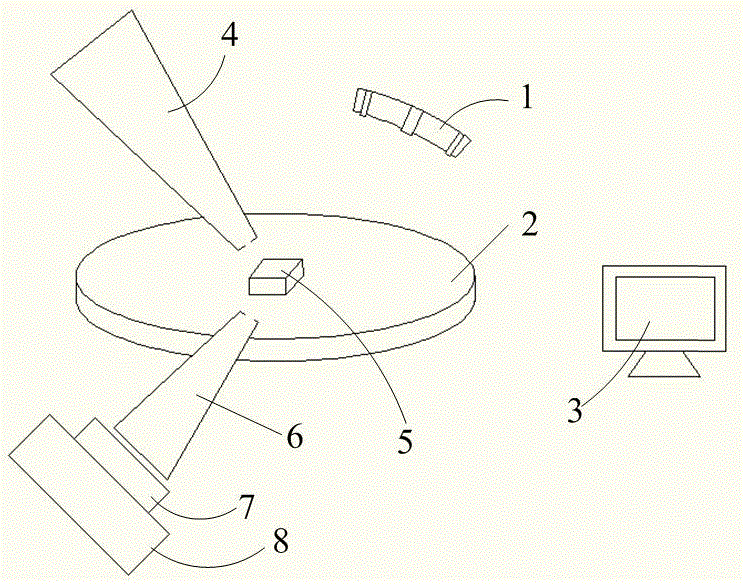

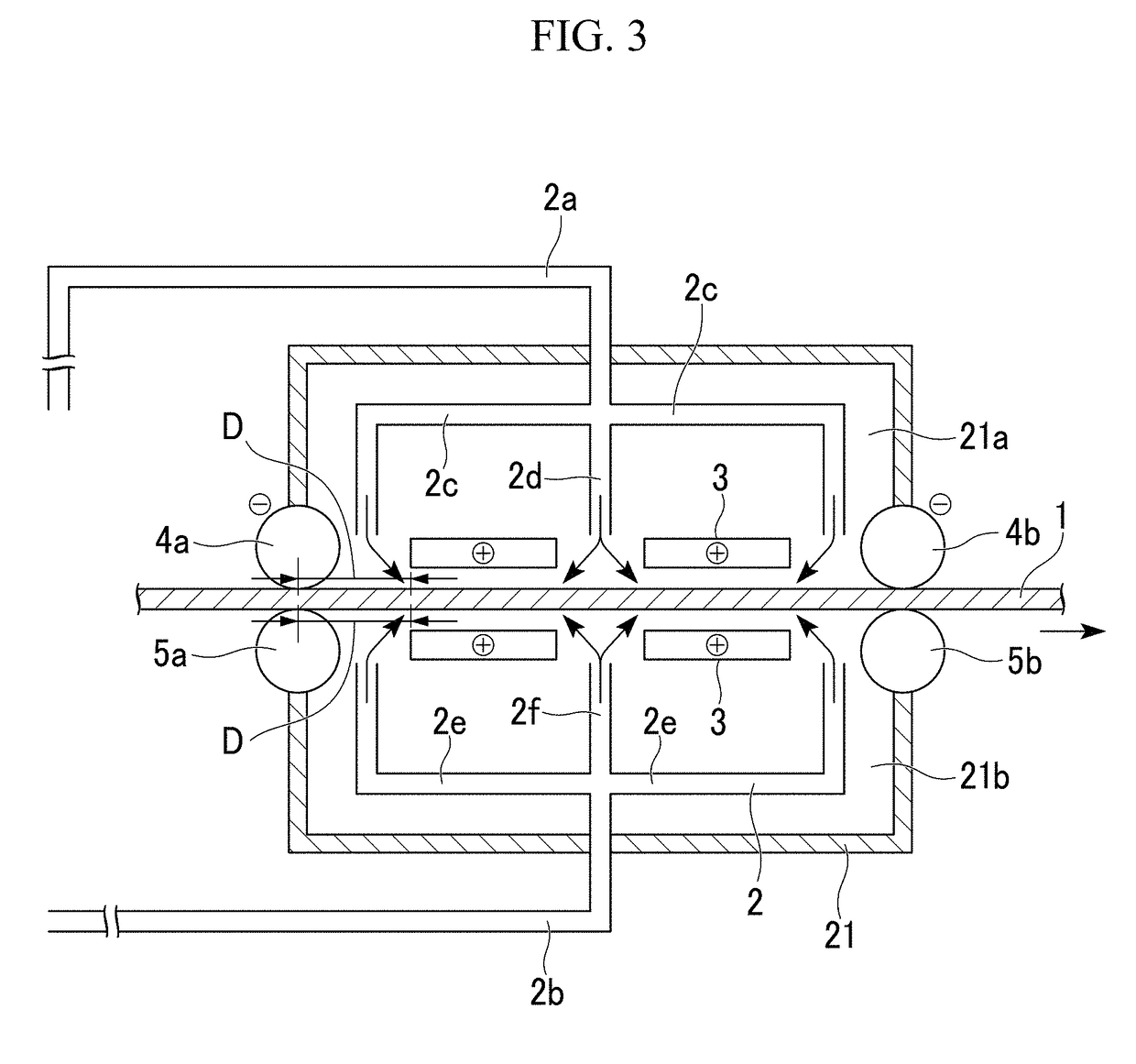

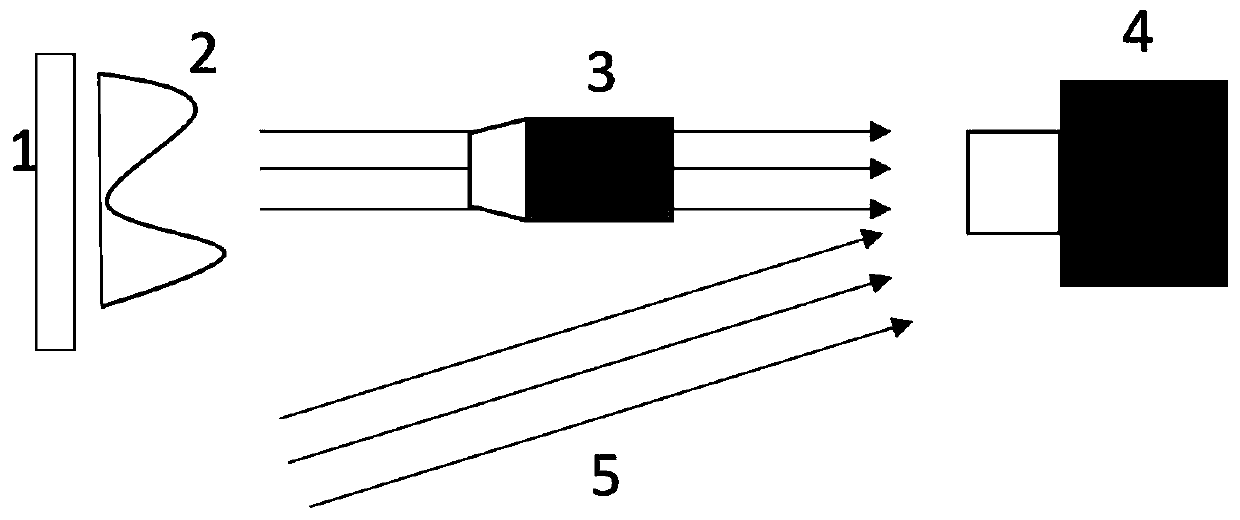

Method and apparatus for measuring temporal response characteristics of digital mirror devices

InactiveUS7095494B2Accurate measurementAngle measurementPhase-affecting property measurementsDamping factorPhotodetector

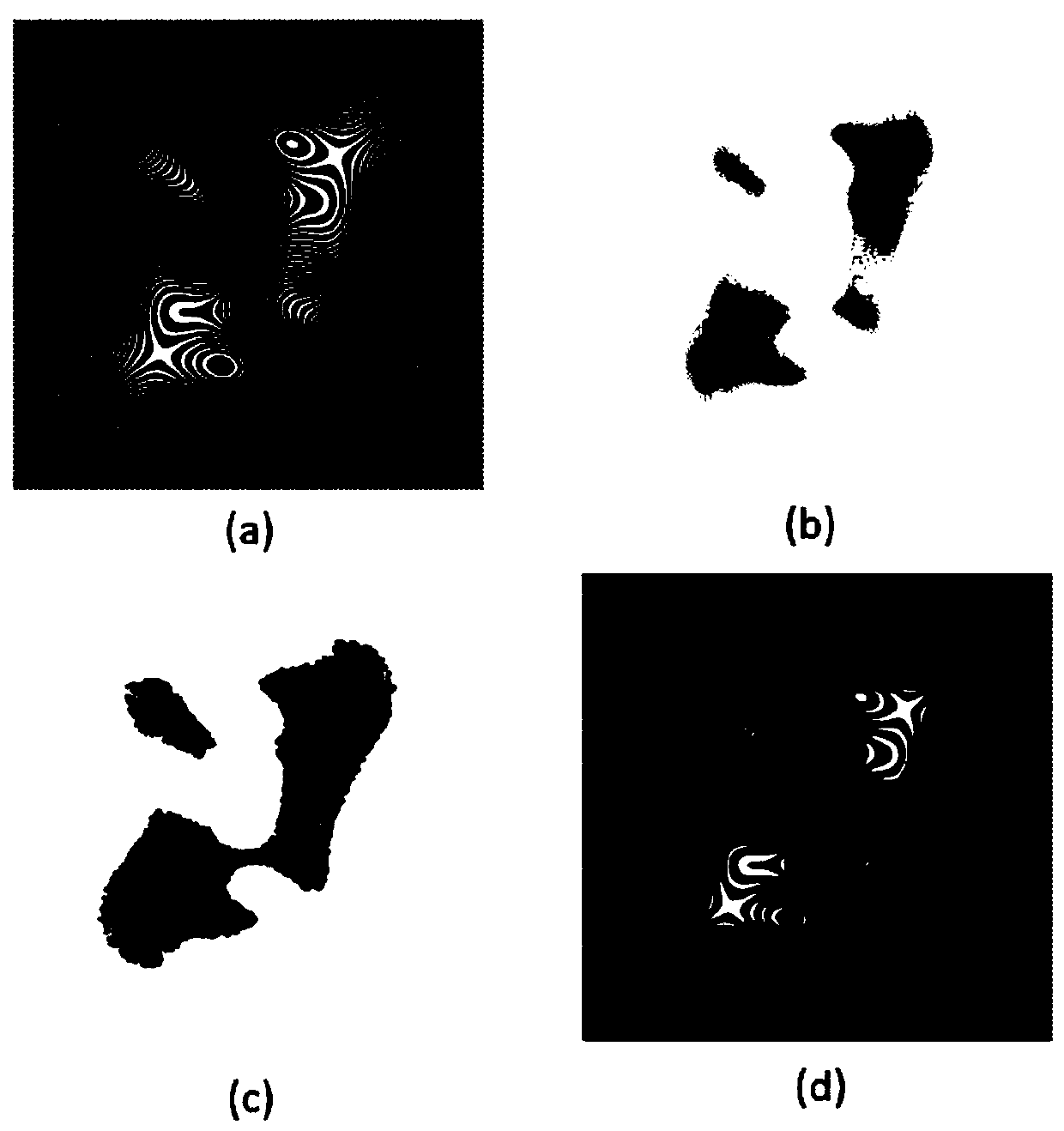

A method and system for measuring the temporal response of a micromirror array to a variety of driving signals. A micromirror array is illuminated with a coherent light source so that a diffraction pattern is reflected from the micromirror array. One or more photodetectors are aligned with spots of light in the diffraction pattern that correspond to orders of the diffraction pattern. Diffraction pattern theory predicts that the intensity of these spots of light will vary as the tilt angle of the micromirrors is changed. Thus, by measuring the relative intensity of the spots of light as the micromirror array is provided with a variety of driving signals, many performance characteristics of the micromirror array can be measured. Some of these characteristics include the impulse response, the forced resonant frequency (i.e. the natural frequency), the damped resonant frequency, the quality factor of the micromirror response, the damping factor of the micromirror response, and the frequency transfer function. According to another aspect of the invention, the electromechanical compliance of the micromirrors in the micromirror array can also be measured. It is further contemplated that all of these measurements can be localized to specific regions on the surface of the micromirror array so that the variance of different characteristics across its surface can be analyzed. Another aspect of the disclosed invention is the measurement of the tilt angle of the micromirror array at a non-biased state.

Owner:TEXAS INSTR INC

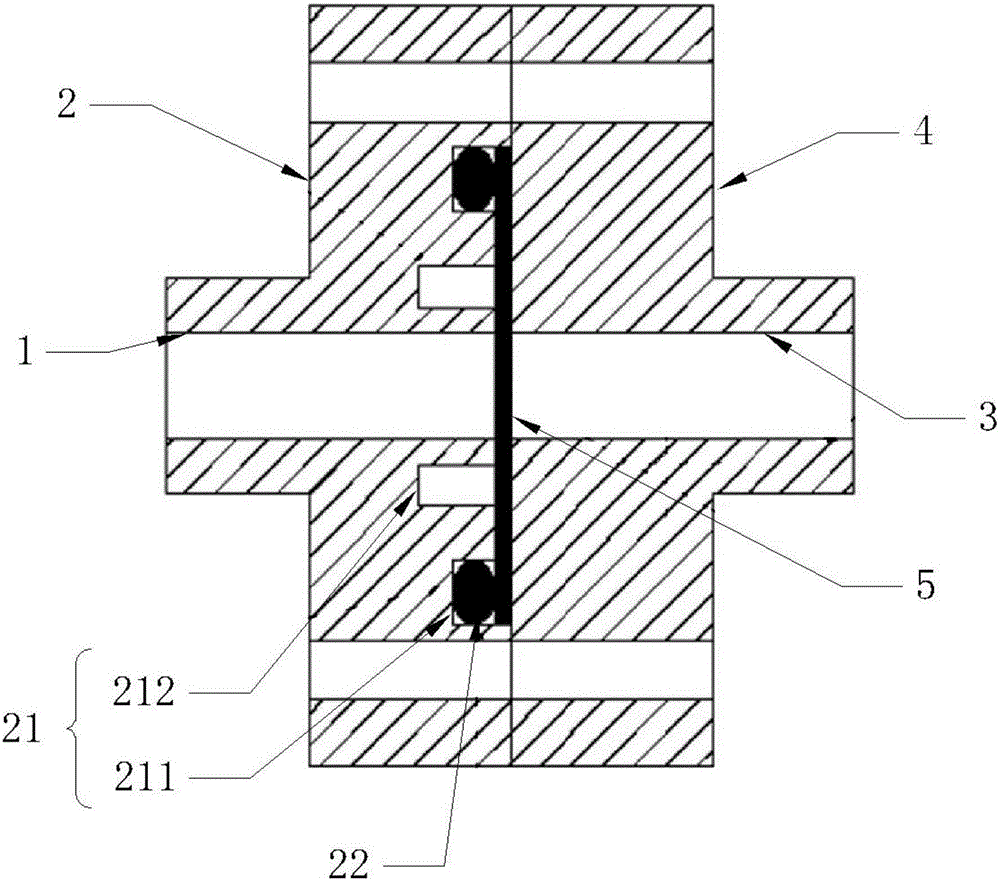

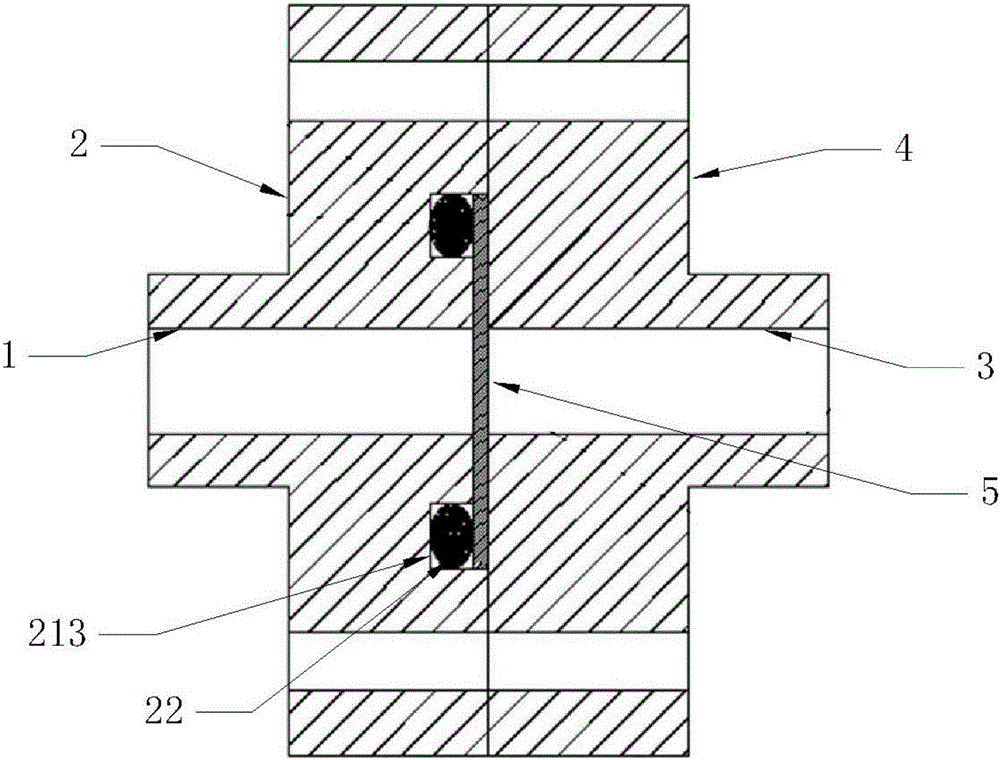

Three-dimensional calibrating measurement device for neutron diffraction stress analysis

PendingCN106770402ASmall space requirementRealize accurate 3D calibrationMaterial analysis using wave/particle radiationStress measurementMeasurement device

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

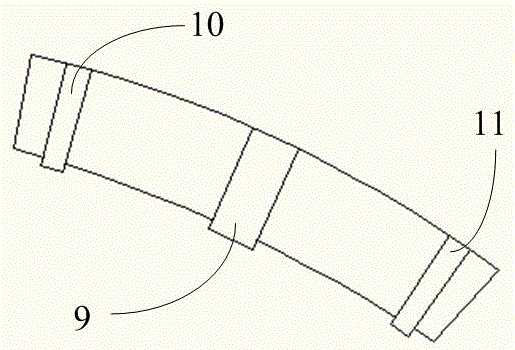

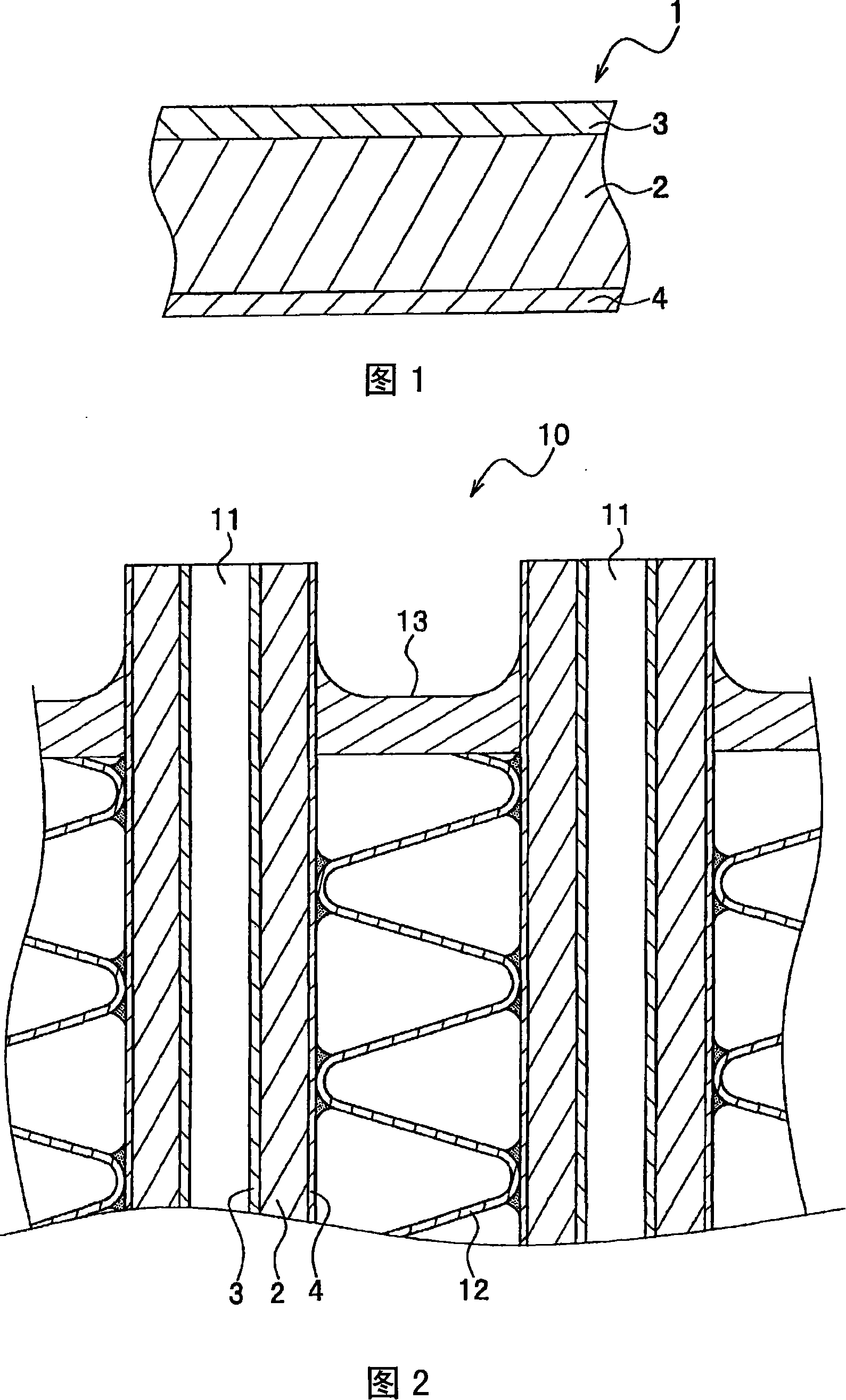

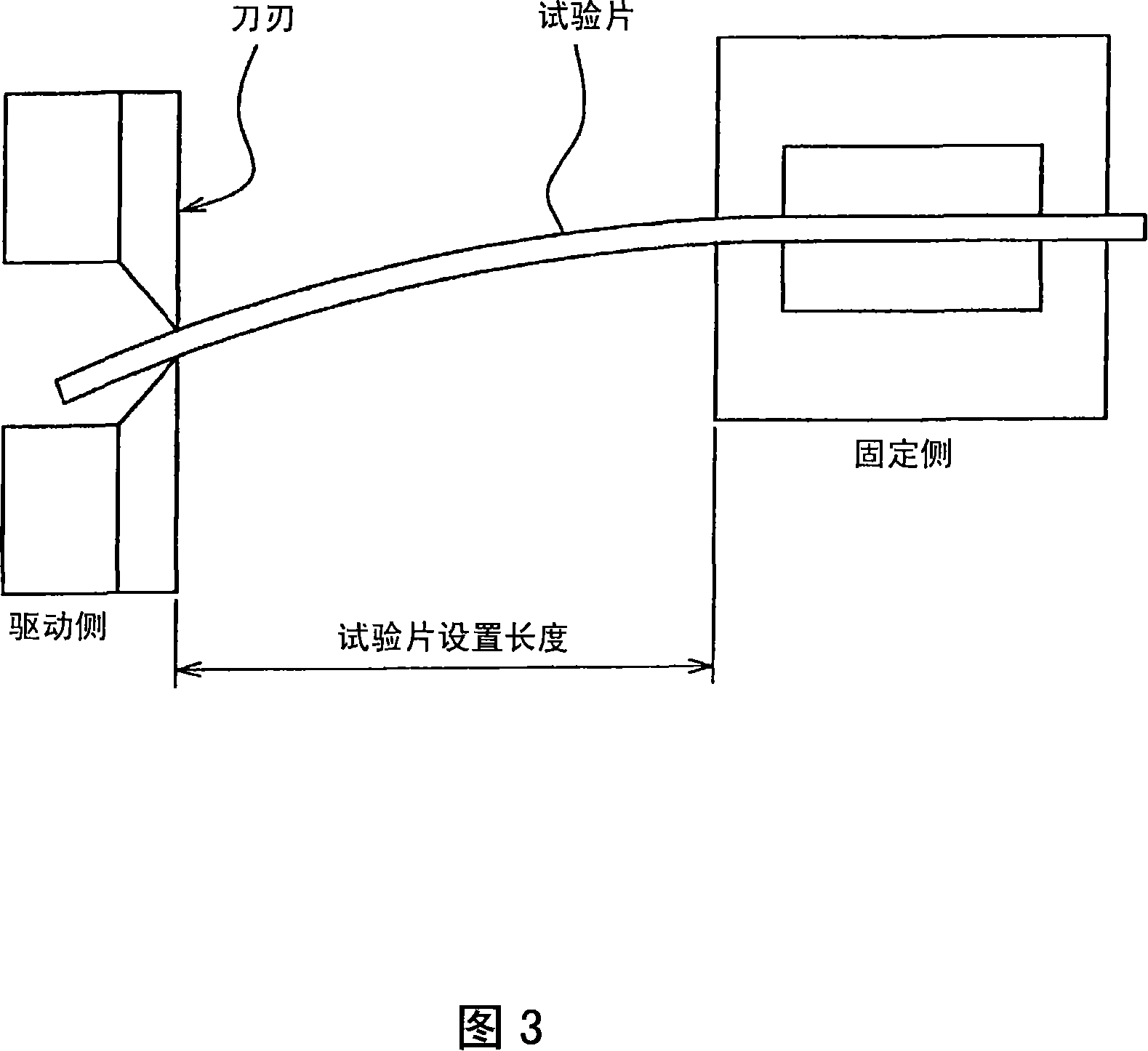

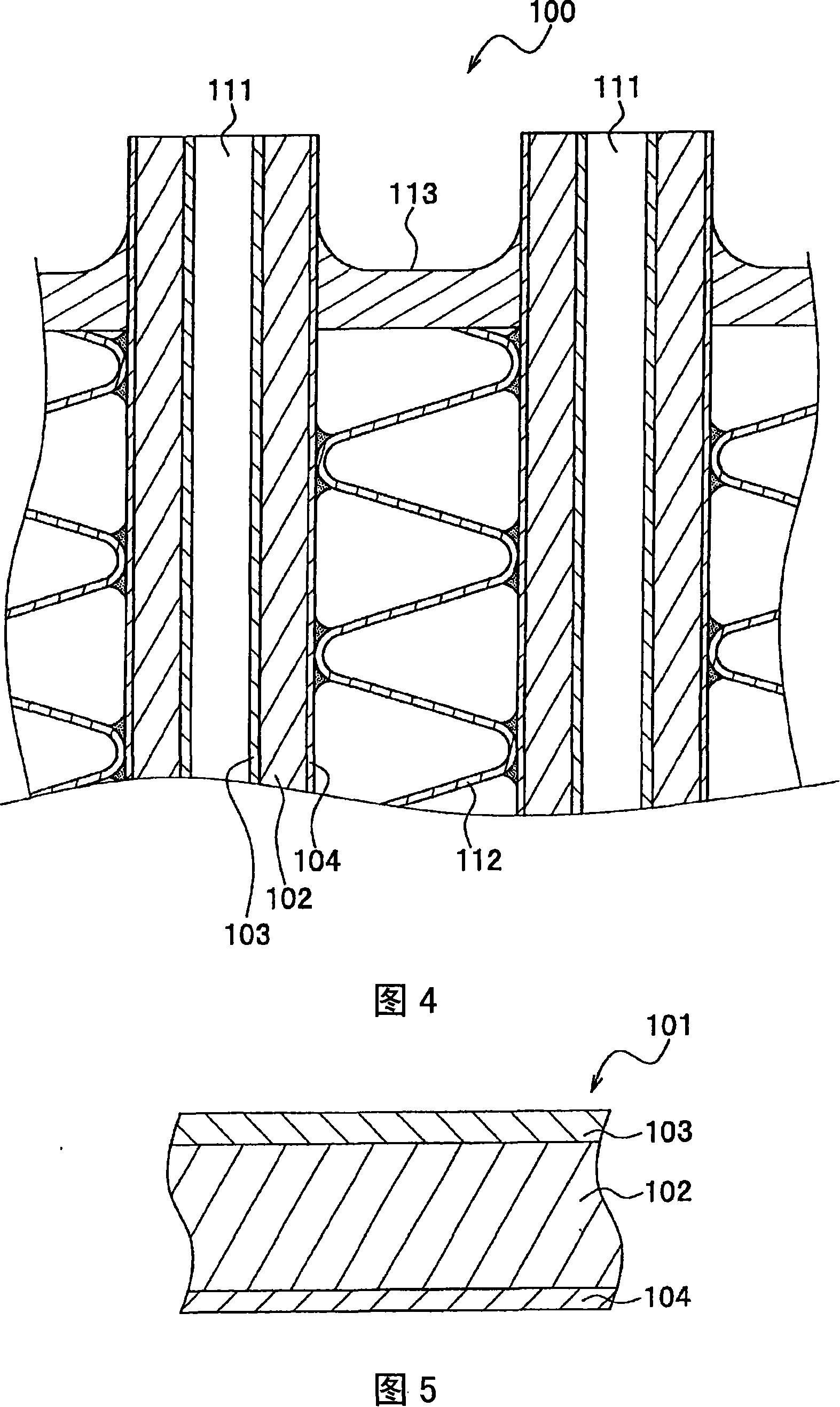

Aluminum alloy brazing sheet and aluminum alloy tube for heat exchanger

InactiveCN101155937AImprove fatigue lifeExtend your lifeStationary conduit assembliesWelding/cutting media/materialsX-rayUltimate tensile strength

Owner:KOBE STEEL LTD

Surface-treated steel sheet

InactiveUS20180100244A1Good film adhesionElectrolytic inorganic material coatingDendriteVanadium oxide

Owner:NIPPON STEEL CORP

Crystalline state Lesinurad intermediate and preparation method thereof

The invention provides a crystalline state Lesinurad intermediate and a preparation method thereof. The invention discloses a crystalline state Lesinurad intermediate (II) and a preparation method thereof. The result of differential scanning calorimetry on the crystalline state Lesinurad intermediate (II) shows that peaks appear in a range of 98 to 102 DEG C. The result of powder X-ray diffraction shows that characteristic peaks appear at (2[theta]): 8.8+ / -0.2 degrees, 10.5+ / -0.2 degrees, 10.6+ / -0.2 degrees, 15.6+ / -0.2 degrees, 22.1+ / -0.2 degrees, and 22.9+ / -0.2 degrees. The solid of crystalline state Lesinurad intermediate (II) is obtained for the first time, the purity is high, the operation of the crystallization method is simple, column chromatography purification is not needed, the method is suitable for industrial production; the obtained crystalline state solid has stable properties, thus storage, transportation, and feeding operation become convenient, and the purity of final product Lesinurad prepared from the intermediate (II) is high.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD

Large-gradient free hook face measurement method

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Device for lowering transmission loss in feeder tube

Owner:上海克林技术开发有限公司

Methods for second harmonic generation imaging of protein crystals

ActiveUS20180052103A1Expand coverageShorten the timeMaterial analysis using wave/particle radiationAnalysis by material excitationHarmonicProtein structure

Owner:PURDUE RES FOUND INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap