Method for preparing flowerlike nanometer cobalt by using anodised aluminum template, and product of same

A technology of anodized aluminum and nano-metal, applied in the direction of nano-technology, can solve the problems of complex operation, high cost, unfavorable large-scale production, etc., and achieve the effect of simple and quick method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

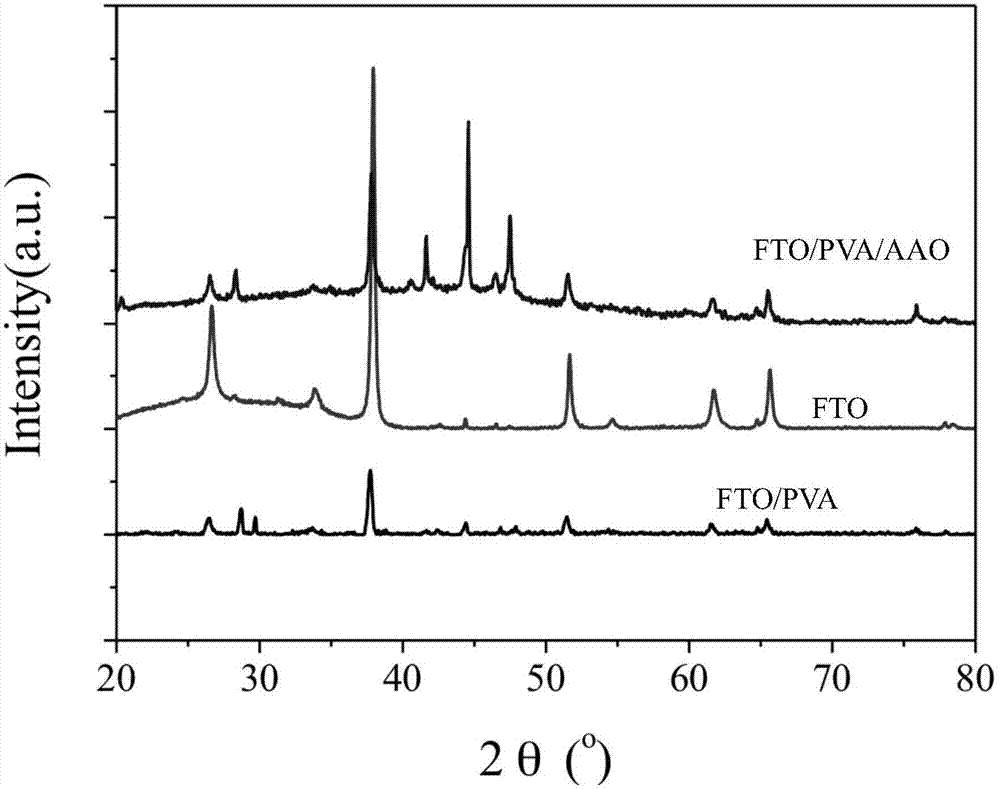

[0031] 1×2cm 2 Half of the conductive glass FTO is spin-coated with a layer of 6% polyvinyl alcohol solution (spin-coating speed 2000rpm), followed by an anodic aluminum oxide (AAO) layer with a pore size of 80-100nm, (the size is 1cm × 1cm, that is, The electrode area participating in the electrochemical reaction is 1cm 2 ), placed in a vacuum oven at 150°C for 2 hours to obtain a working electrode. Prepare 0.1 mol / L cobaltous sulfate and boric acid aqueous solutions respectively, and use them as the electrolyte of the three-electrode system after mixing.

[0032] Using a three-electrode system, the counter electrode is a platinum sheet electrode, the reference electrode is a saturated calomel electrode, the current-time method is selected, the voltage is -1.5V, and the electrodeposition is carried out on the working electrode, and the deposition time is 60min. After electrodeposition, the anodized aluminum template was removed with 1mol / L sodium hydroxide solution, and fi

Embodiment 2

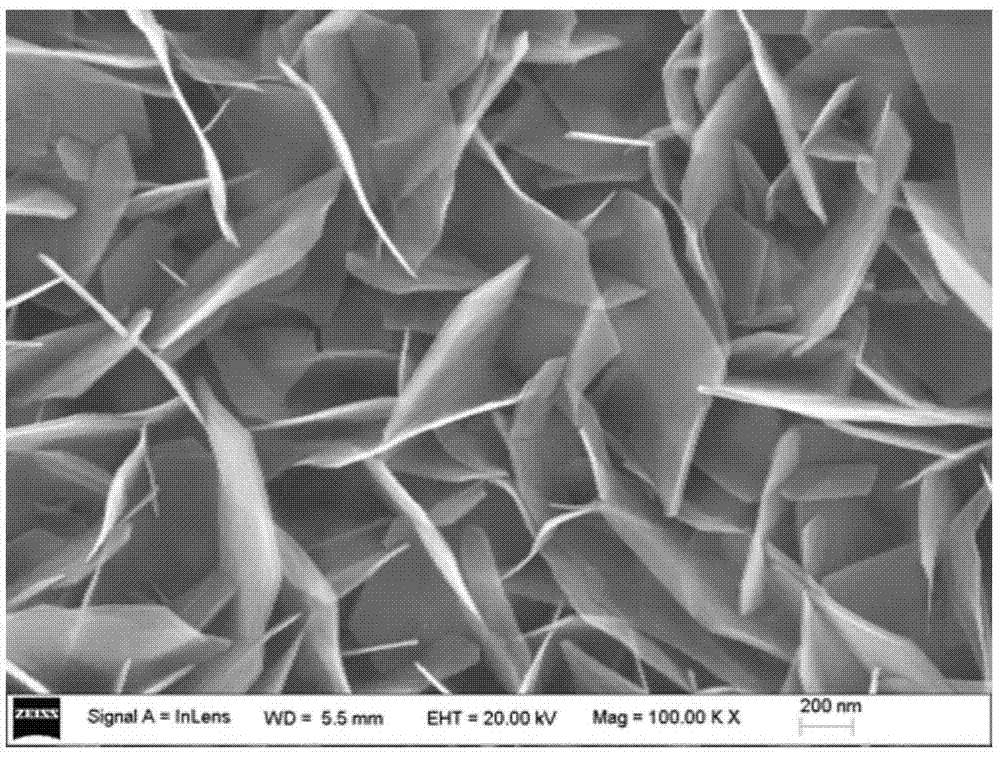

[0035] Selectively coat a layer of 6% polyvinyl alcohol solution on the conductive glass FTO, then adhere the anodic aluminum oxide (AAO) layer with a pore size of 40-70nm, put it in a vacuum oven at 150°C for 2 hours, and obtain the working electrode (size 1cm x 1cm). Prepare 0.1 mol / L cobaltous sulfate and boric acid aqueous solutions respectively, and mix them as the electrolyte solution of the three-electrode system.

[0036] Using a three-electrode system, the counter electrode is a platinum sheet electrode, the reference electrode is a saturated calomel electrode, the current-time method is selected, the voltage is -1.5V, and the electrodeposition is carried out on the working electrode, and the deposition time is 60min. After electrodeposition, the anodized aluminum template was removed with 1mol / L sodium hydroxide solution, and finally the working electrode was cleaned three times with ultrapure water.

[0037] The SEM spectrum of the obtained material is as image

Embodiment 3

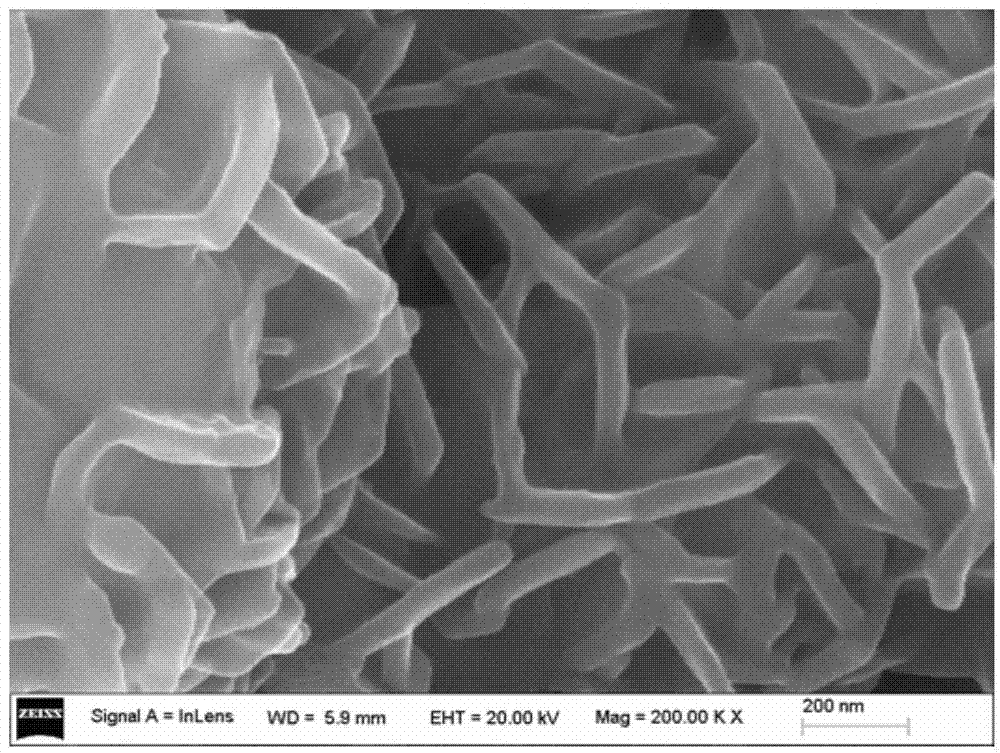

[0039] Spin-coat a layer of 6% polyvinyl alcohol solution on the conductive glass FTO (spin-coating speed 2000rpm), then adhere an anodic aluminum oxide (AAO) layer with a pore size of 160-200nm, and put it in a vacuum oven at 150°C for 2 hours , to get the working electrode. Prepare 0.1 mol / L cobaltous sulfate and boric acid aqueous solutions respectively, and mix them as the electrolyte solution of the three-electrode system.

[0040] Using a three-electrode system, the counter electrode is a platinum sheet electrode, the reference electrode is a saturated calomel electrode, the current-time method is selected, the voltage is -1.5V, and the electrodeposition is carried out on the working electrode, and the deposition time is 60min. After electrodeposition, the anodized aluminum template was removed with 1mol / L sodium hydroxide solution, and finally the working electrode was cleaned three times with ultrapure water.

[0041] The SEM spectrum of the obtained material is as

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap