Non copper pipe lead electrolytic refining energy-saving high-efficiency environment protection novel technique

A new technology of lead electrolysis, which is applied in the field of copper-free lead electrolysis refining, energy-saving, high-efficiency and environmental protection, can solve the problems of inability to guarantee product quality and output stability, inability to fully eliminate electrolyte concentration difference, and bulky step-down rectifier transformers and other problems, to achieve the effect of preventing copper elements from entering the electrolyte, eliminating poor contact, and reducing management workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

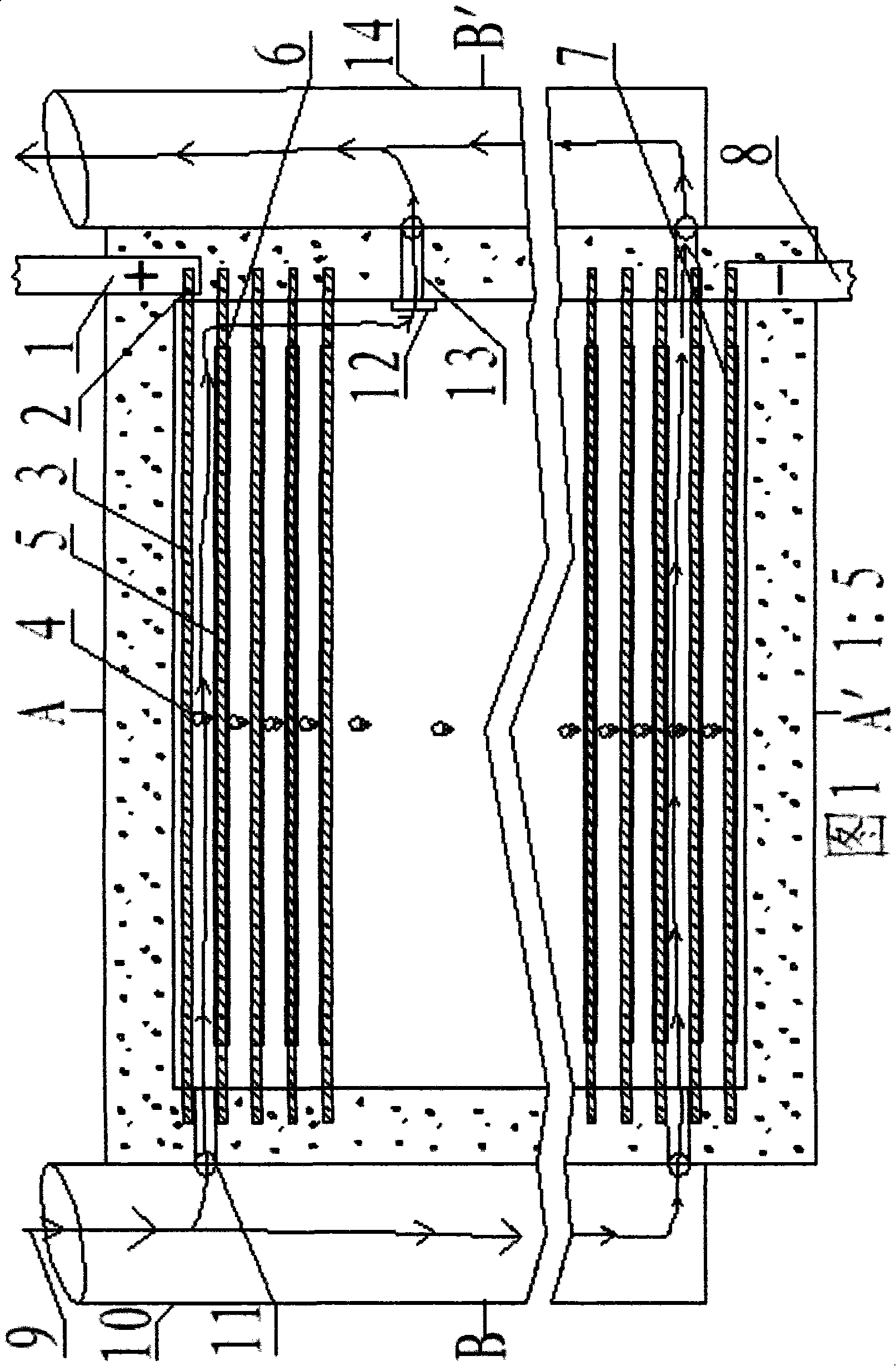

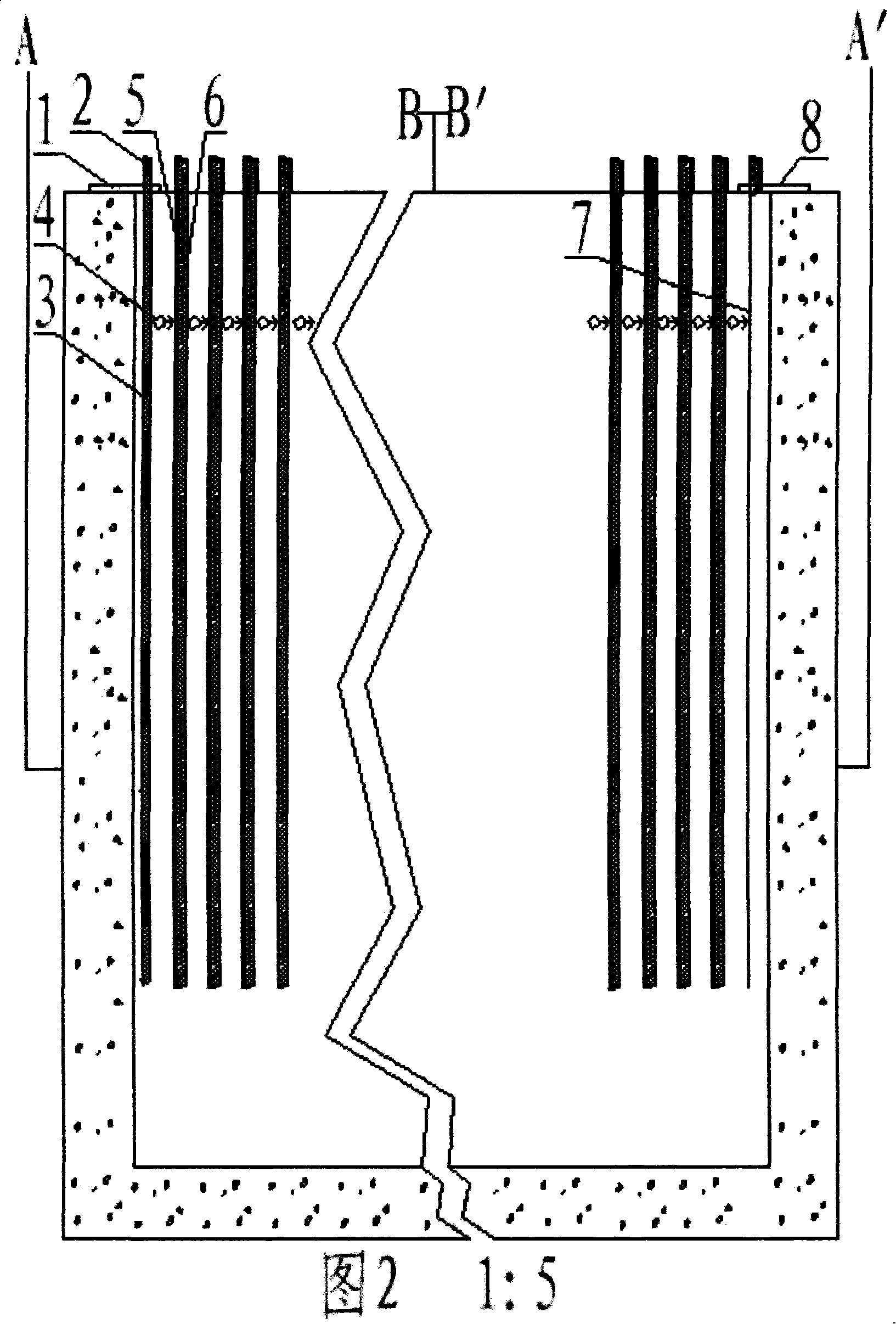

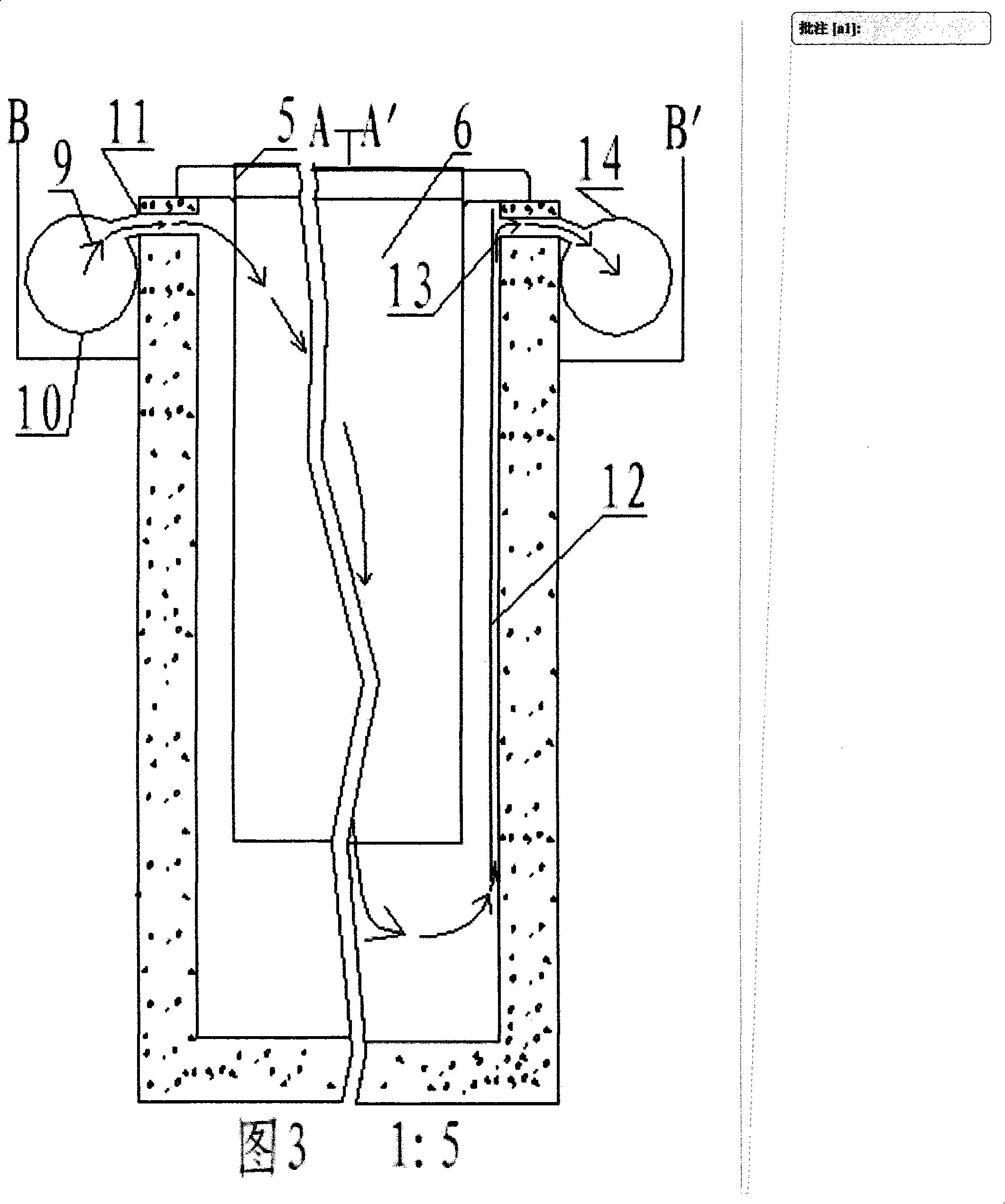

[0036] 1. Electrolysis process: the working current flows from the positive electrode 1 of the electrolysis power supply to the anode plate 3 through the first anode plate lug 2 at the A end of the electrolytic cell, and the positive current electrochemically reacts at the interface between the anode plate 3 and the electrolyte, making Metallic crude lead is oxidized and transformed into ionic lead ions 4, which are distributed in the electrolyte. Under the action of electric current, the lead ions 4 are transferred to the negative electrode and flow to the cathode surface 5 on the front side of the second anode plate with the cathode sheet attached. On the interface between the electrolyte and the cathode sheet, it combines with electrons and reduces to pure metallic lead. The current flows from the back side 6 of the second anode plate to the cathode surface on which the cathode sheet is pasted on the front of the third anode plate. Through such continuous transmission, the las

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap