Method for preparing benzaldehyde by nano MnO2

A benzaldehyde and nano technology, applied in the field of preparing benzaldehyde from nano MnO2, can solve the problems of high equipment investment, harsh production conditions, many side reactions, etc., and achieve the effects of simple reaction device, mild reaction conditions and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Best practice:

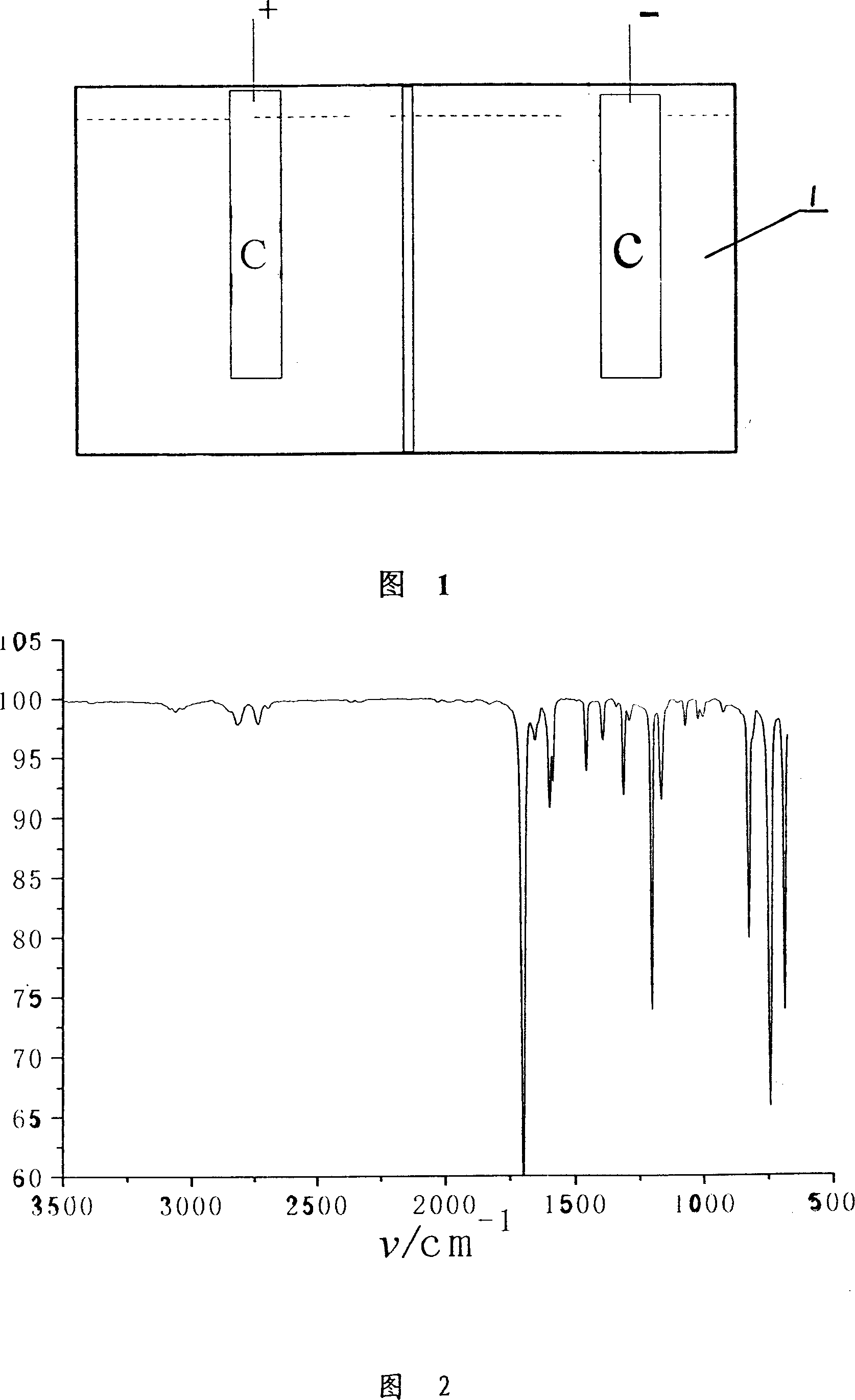

[0032] Referring to Figure 1, nano-MnO 2 The method for preparing benzaldehyde may further comprise the steps:

[0033] 1 Provide an electrolytic cell, the electrolytic cell has an anode chamber and a cathode chamber, the anode chamber and the cathode chamber are separated by a cation exchange membrane, the anode chamber and the cathode chamber respectively have an anode and a cathode, and the anode and the cathode are graphite electrodes;

[0034] 2 Add 1M MnSO in the anode chamber 4 and 20% benzyl alcohol solution as electrolyte, add 0.5mol / L H in the cathode chamber 2 SO 4 solution as electrolyte;

[0035] 3. The electrode is energized to carry out the electrolysis reaction, and at the same time, air is blown in to stir the electrolyte in the anode chamber;

[0036] 4. An ultrasonic generator is provided, and the electrolytic cell is placed in the ultrasonic generator, so that the electrolytic reaction is carried out in the ultrasonic wave;

[0

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap