Roasting-leaching method of fine vanadium slags

A roasting and vanadium slag technology, applied in the metallurgical field, can solve problems such as environmental pollution and inability to meet the requirements of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Preparation of fine vanadium slag

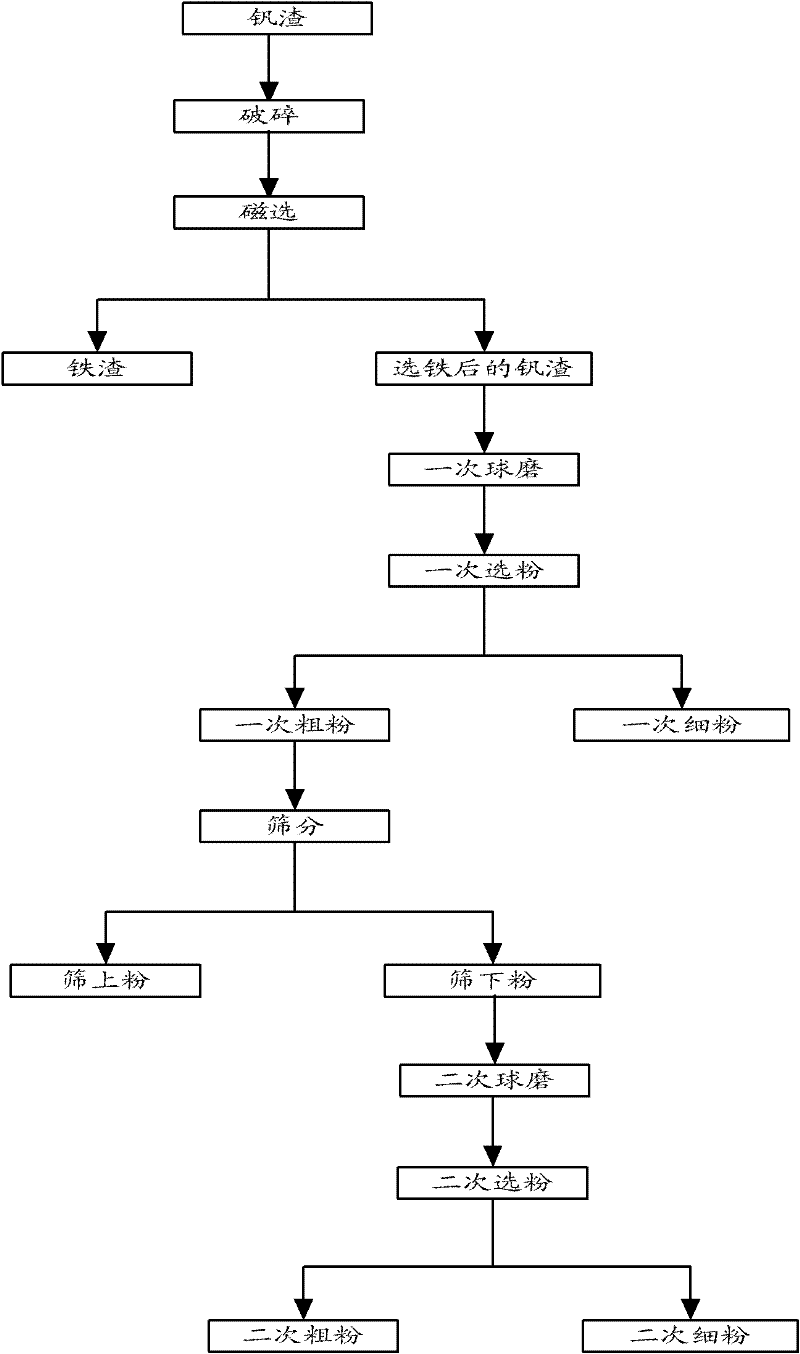

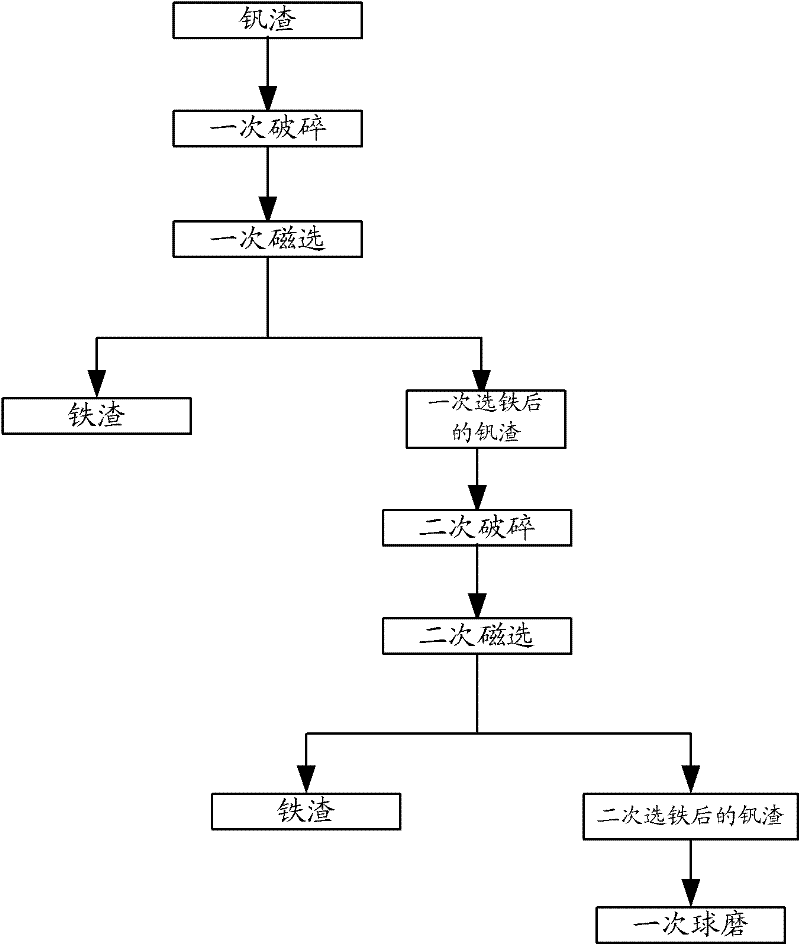

[0041] refer to figure 1 , according to an embodiment of the present invention, the method for preparing fine vanadium slag from raw material vanadium slag comprises the following steps:

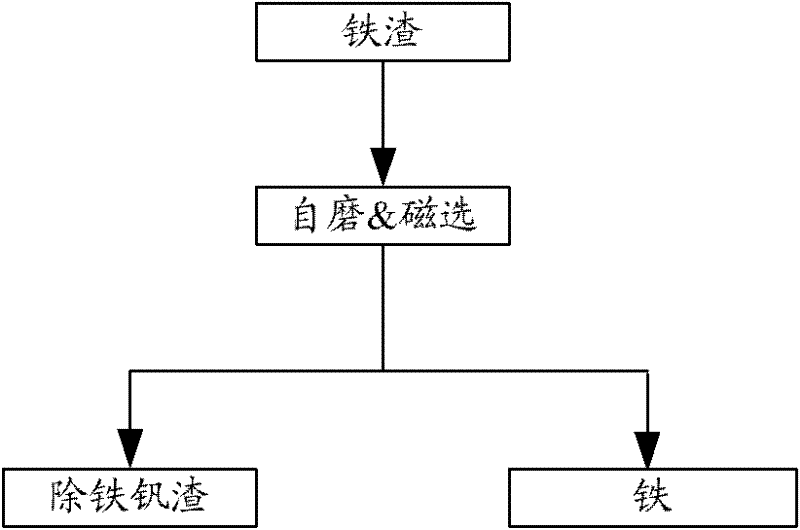

[0042] like figure 1 As shown, first, the raw vanadium slag is crushed, and then iron is magnetically separated to obtain iron slag and vanadium slag after iron selection. According to the embodiment of the present invention, the raw vanadium slag used in the present invention is not particularly limited, and may be any material containing vanadium. According to a specific example of the present invention, the raw vanadium slag is the "slag" of vanadium-titanium magnetite after steelmaking, thus, vanadium can be recovered from waste materials, reducing industrial costs. The applicant found that vanadium-titanium magnetite The calcium content of the "slag" after steelmaking is low (the content of calcium oxide is less than 3.5% by weight), so the obt

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap