Method for preparing 5-methylthienyl-2-thiol from levulinic acid

A technology of levulinic acid and methylthiophene, applied in the direction of organic chemistry, etc., to achieve the effects of mild reaction conditions, simple steps and high product yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

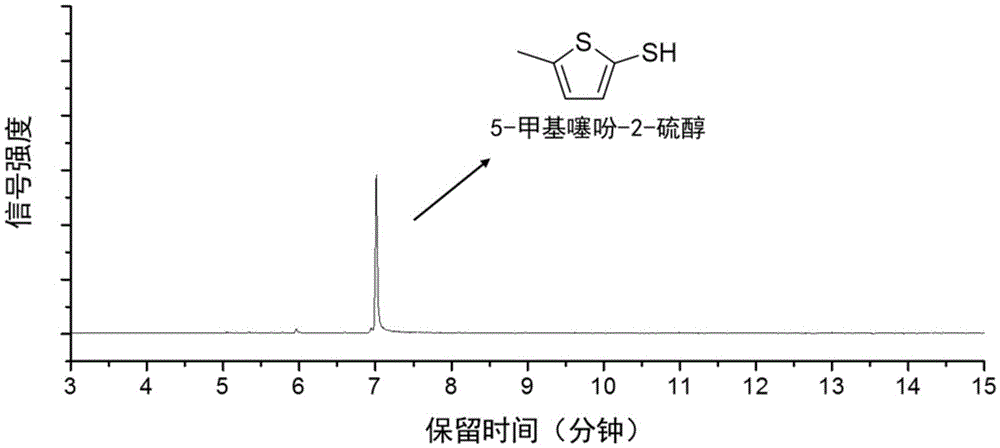

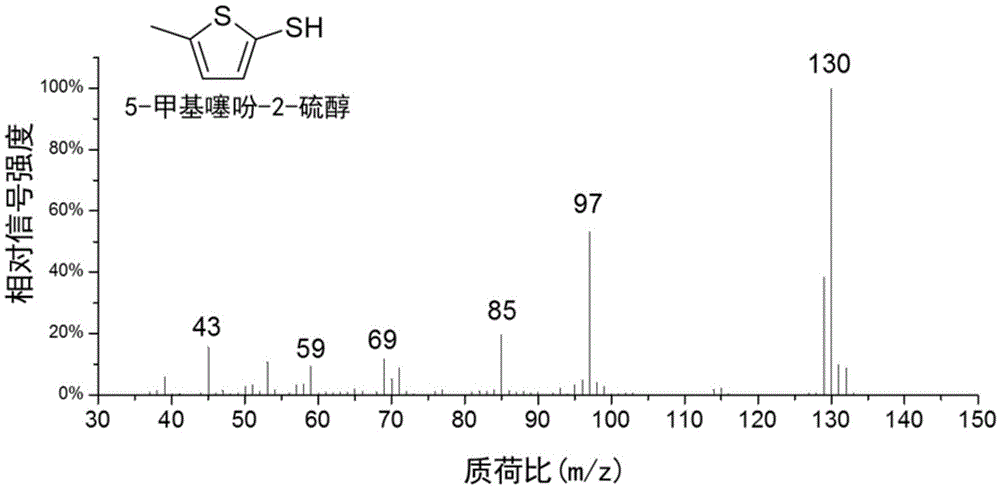

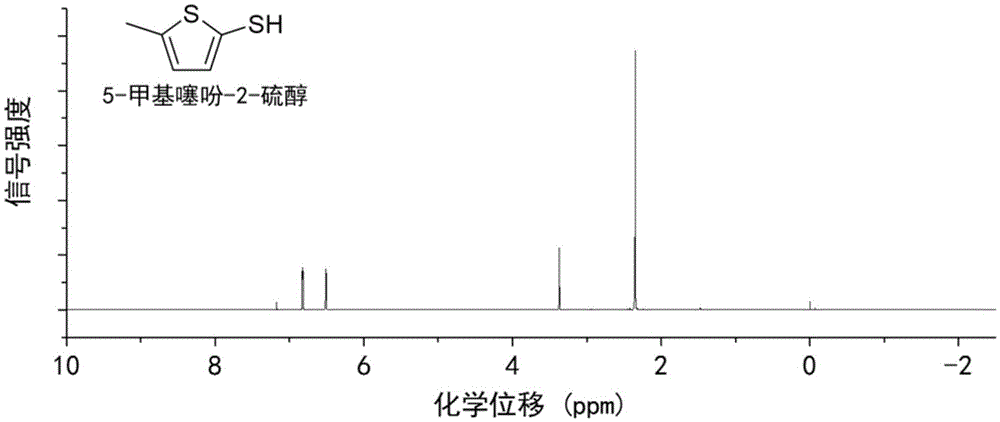

Embodiment 1

[0031] Add 0.23g of levulinic acid to 15mL of toluene, and add Lawson's reagent twice the amount of the raw material, and react at 100°C for 5h under 1bar nitrogen atmosphere to obtain a light yellow transparent liquid. The solution was washed with 2 times the volume of sodium carbonate solution with a mass concentration of 10%, and then separated by vacuum distillation to obtain 5-methylthiophene-2-thiol with a yield of 62%.

Embodiment 2

[0033] Add 0.06 g of levulinic acid to 10 mL of xylene, and add Lawson's reagent in an amount 1 times that of the raw material, and react for 1 h at 110° C. under a nitrogen atmosphere of 1 bar to obtain a light yellow transparent liquid. The solution was washed with 1 volume of sodium hydrogen carbonate solution with a mass concentration of 5%, and then separated by vacuum distillation to obtain 5-methylthiophene-2-thiol with a yield of 46%.

Embodiment 3

[0035] Add 0.6 g of levulinic acid to 20 mL of toluene, and add 1.5 times the amount of Lawson's reagent as the raw material, and react at 110 ° C for 4 h in an air atmosphere of 1 bar to obtain a light yellow transparent liquid. The liquid was washed with 3 times volume of sodium carbonate solution with a mass concentration of 7.5%, and then separated by vacuum distillation to obtain 5-methylthiophene-2-thiol with a yield of 64%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap