Multi-layer two-dimensional topological material-based adjustable three-dimensional optical stealth cloak

A two-dimensional topology and three-dimensional optical technology, which is applied in optics, nonlinear optics, clothing, etc., can solve the problem that the stealth function does not have tunability, etc., and achieve the effects of prolonging camouflage time, saving energy, and huge application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

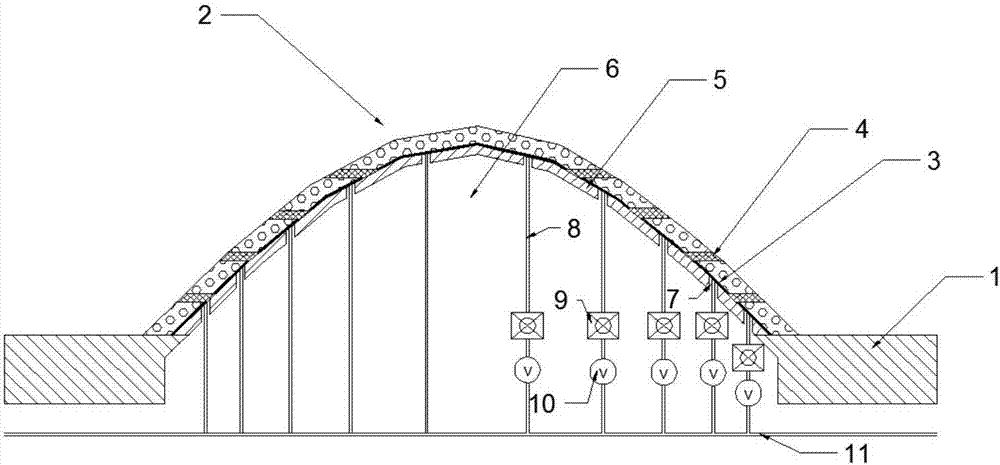

[0030] First, an internal support shell 5 is formed on the substrate 1 by a material growth process, as shown in Figure 2(a);

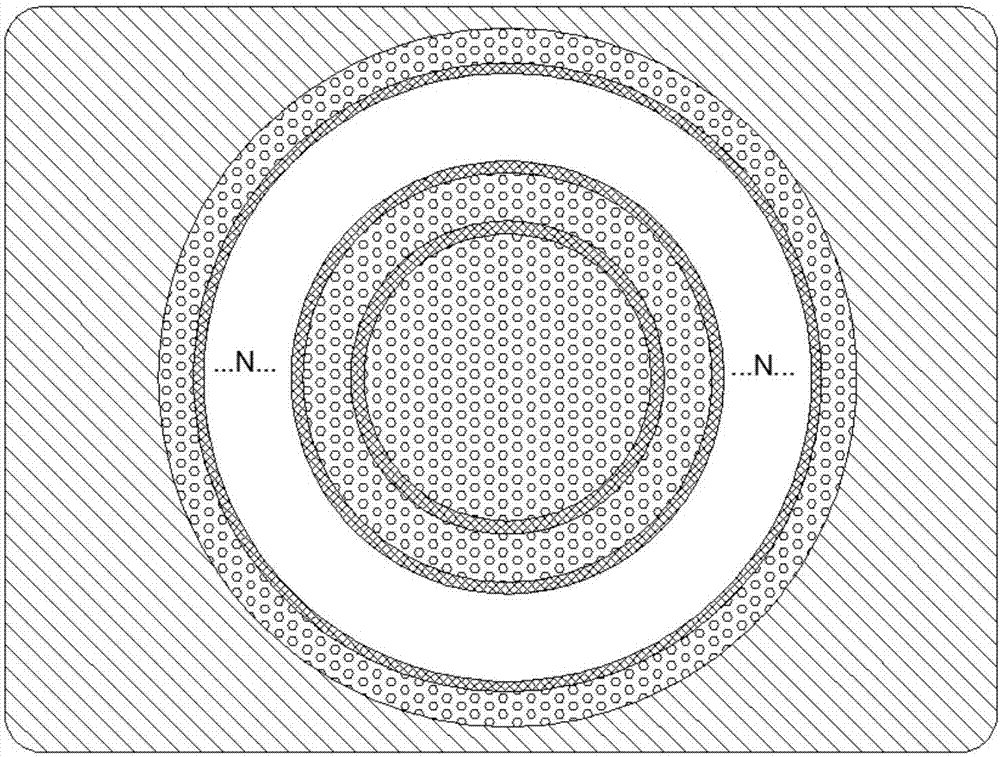

[0031] Then, through the material growth process and mask process, the designed two-dimensional topological material ring layer is superimposed layer by layer on the outer surface of the substrate 1 and the inner support shell 5 from bottom to top to realize the surface coverage ring of N layers of two-dimensional topological material Layer 2, as shown in Figure 2(b). Among them, the design of the surface ring layer and the internal support shell of the two-dimensional topological material can use algorithms such as finite time domain difference method and finite element method. The metal thin layer patch 3 is processed between the inner ring wall of the N-layer two-dimensional topological material surface covering ring layer 2 and the outer wall of the inner support shell 5 through a coating process.

[0032]Corresponding to each thin metal patch 3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap