Molding die for injection molding and method for producing composite product

A metal mold and injection molding technology, which is applied to other household appliances, coatings, etc., can solve the problems of large number of processes, labor and time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

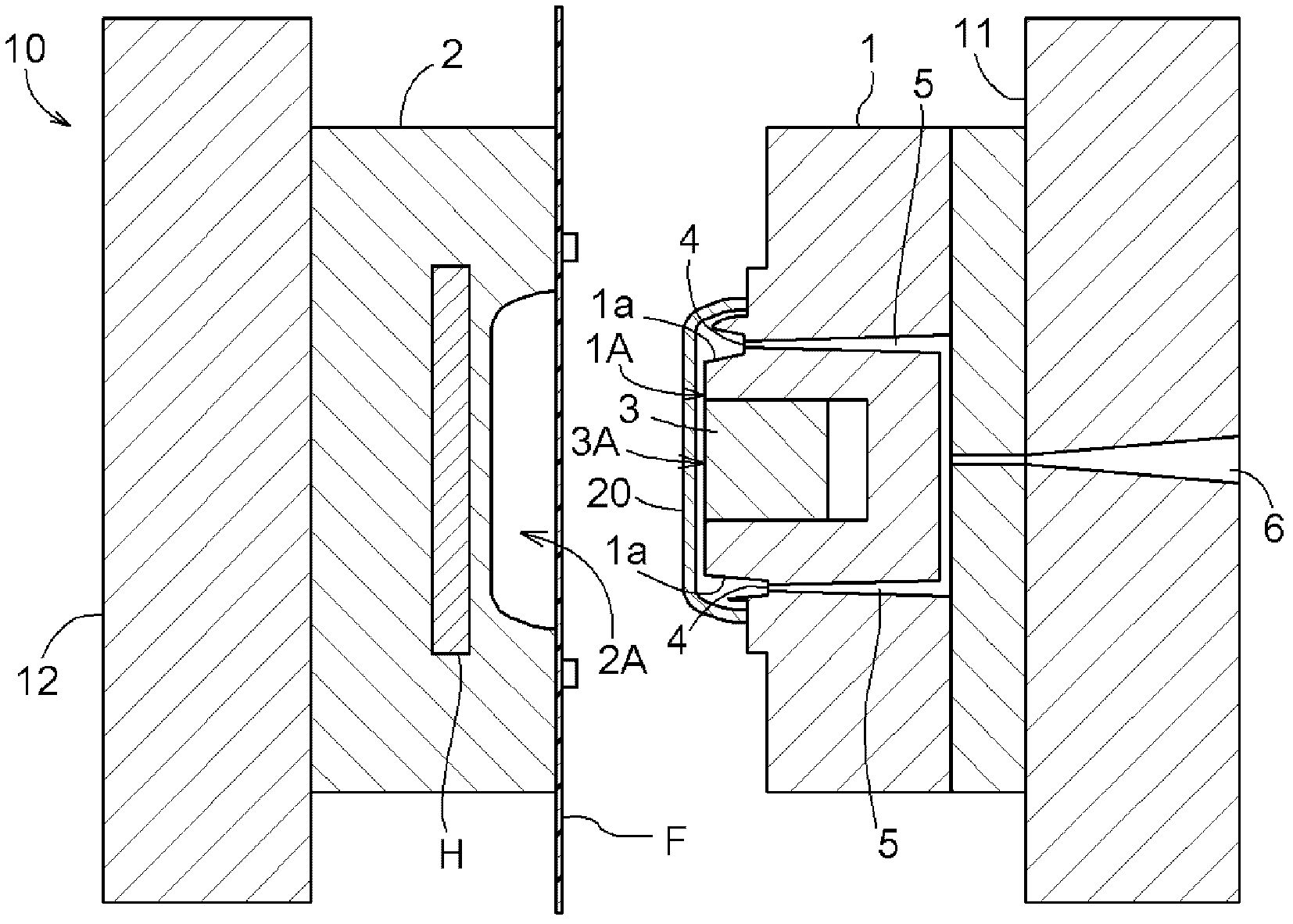

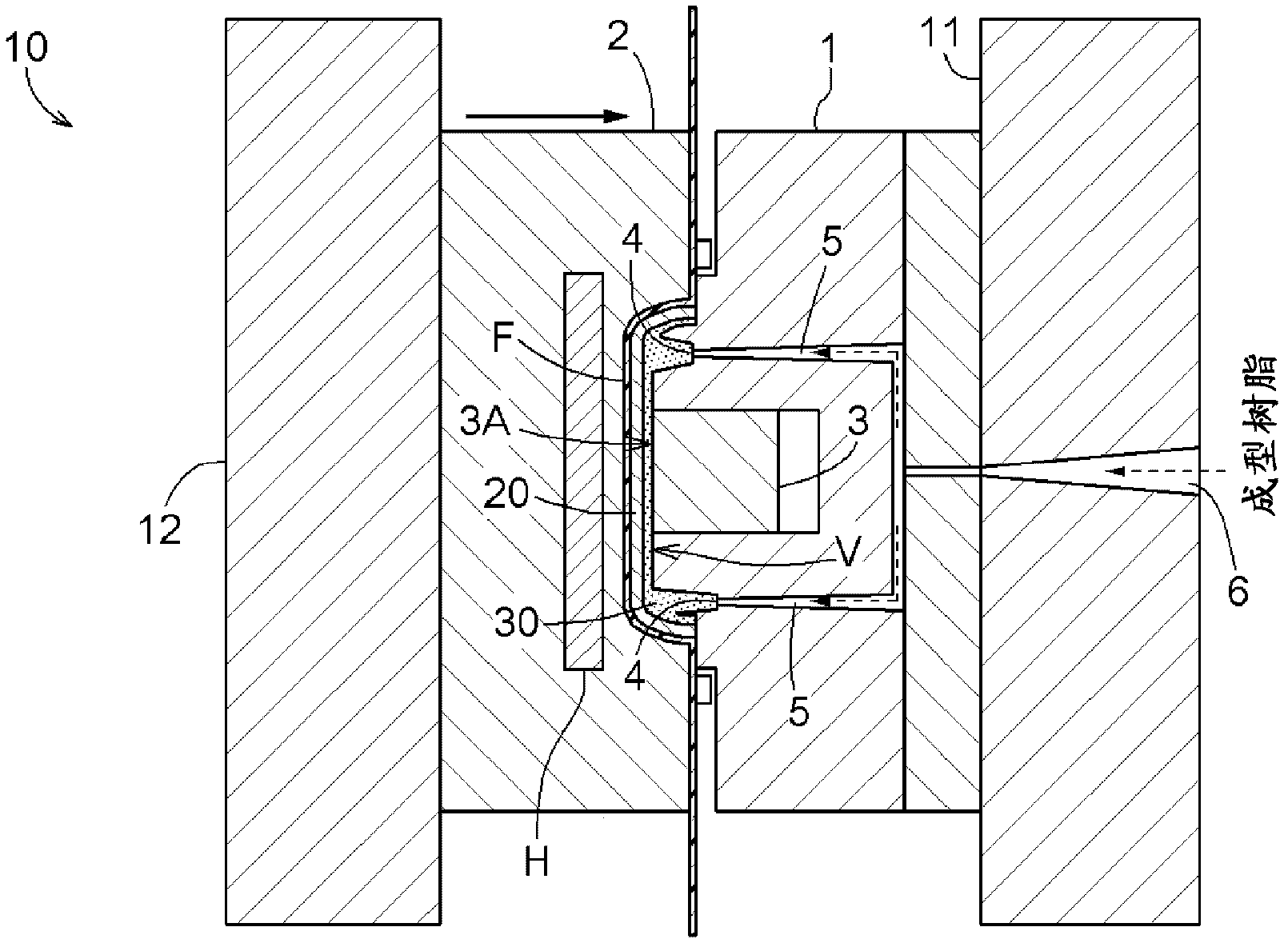

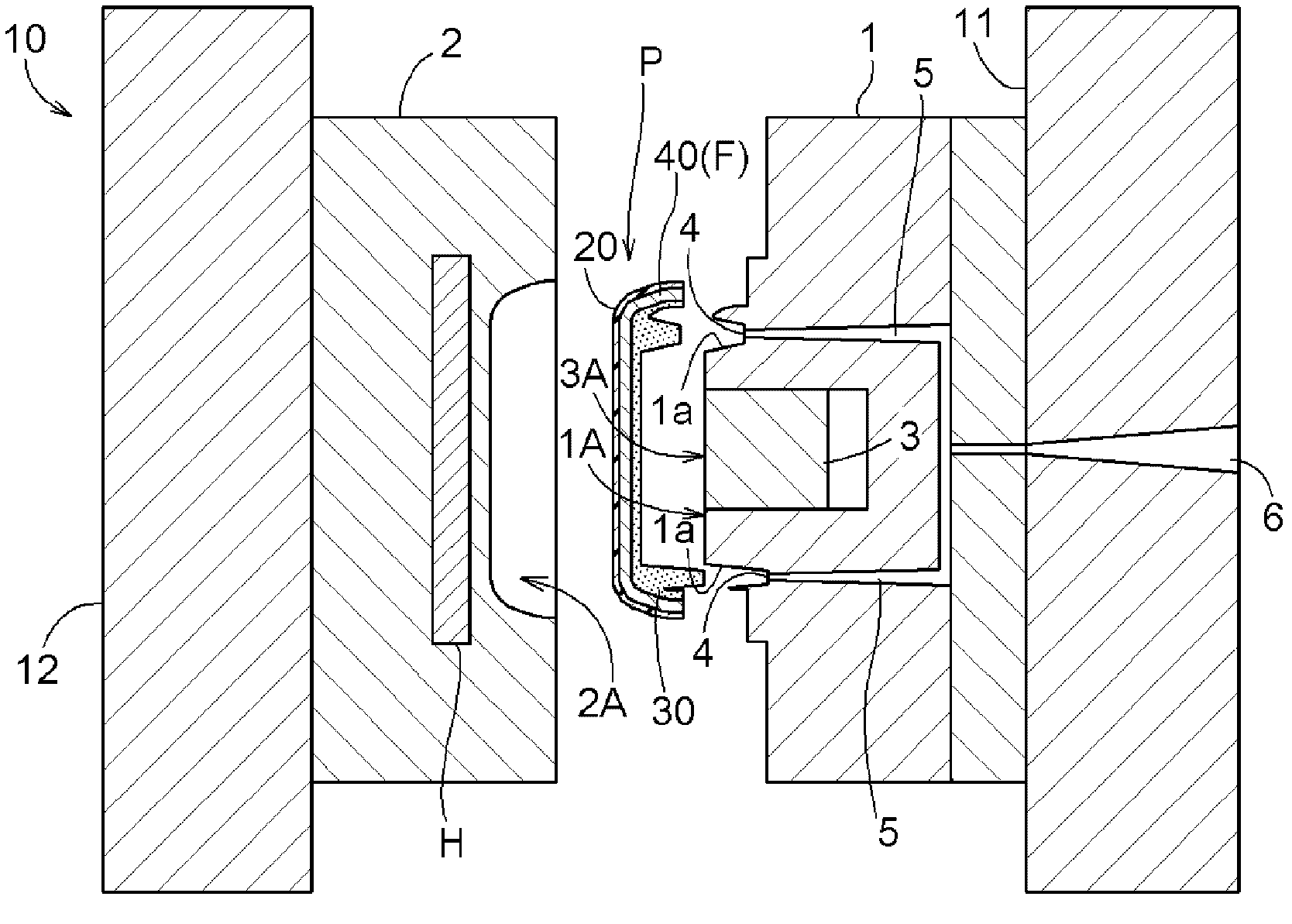

[0028] Figure 1 ~ Figure 3 All are diagrams showing a molding process of a composite product using the injection molding die according to the present invention. Figure 4 yes figure 2 An enlarged view of the main part of .

[0029] [metal body]

[0030] The metal body 20 has a flat plate shape as a whole, and a raised portion 11 is formed around it. In order to facilitate the formation of the decorative layer, surface treatment is performed on the surface of the metal body 20 in advance, or a sheet that is easy to bond the decorative layer is pasted in advance. In addition, in order to facilitate the fixation of the injected resin, an adhesive layer is applied to the back of the metal body 20 in advance, or a layer with high adhesiveness is formed by chemical treatment. The surface treatment of the metal body 20 and the coating materials on the front and back sides need to be selected according to various combinations of the metal of the metal body 20, the decorative layer

Embodiment approach 2

[0044] When the resin part 30 is not molded on the entire back surface of the metal body 20, but only in the peripheral part, for example, the resin part 30 is molded, as Figure 5 As shown, the front end portion 3a of the slide mold 3 is protruded into the cavity V, and the front end surface 3A is pressed against the back surface of the metal body 20 after the mold is closed. When the molten resin is injected with the tip portion 3a of the slide mold 3 protruding into the cavity V, no molten resin is injected into the portion of the tip surface 3A that presses the back surface of the metal body 20 . Therefore, the resin portion 20 is formed only on the peripheral portion of the metal body 20 .

[0045] In this case, of course, the heat of the resin is not transmitted to the surface side corresponding to the portion of the back surface of the metal body 20 where the molten resin is not injected, and the surface temperature of the metal body 20 may be lowered only in this portion.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap