Rubber composition for improving performance of tire on ice and snow field and tire

A rubber composition and tire technology, which is applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of easy sideslip, rolling, unable to break the water film, and easy hardening of the tread, so as to shorten the braking time. Effects for distance, comfort, and improved grip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of the above-mentioned rubber composition of the embodiment of the present invention is specifically:

[0055] Primary mixing to prepare masterbatch: add raw rubber such as natural rubber, carbon black, white carbon black, zinc oxide, stearic acid, aromatic hydrocarbon oil, anti-aging agent, and glass flakes into Banbury internal mixer in sequence, and can be Mixing at 130°C for 120 seconds, then debinding at 160°C;

[0056] Final mixing to prepare final rubber mix: Add the obtained masterbatch, sulfur, accelerator, etc. into the internal mixer, mix at 105°C for 120 seconds, and then release the material to obtain a rubber composition.

[0057] The vulcanization condition of the rubber composition: heating at 160° C. for 20 minutes to prepare a physical test piece.

[0058] The embodiment of the present invention also provides a tire, which uses the vulcanized rubber of the aforementioned rubber composition as a tread, and is a nail-free tire. In t

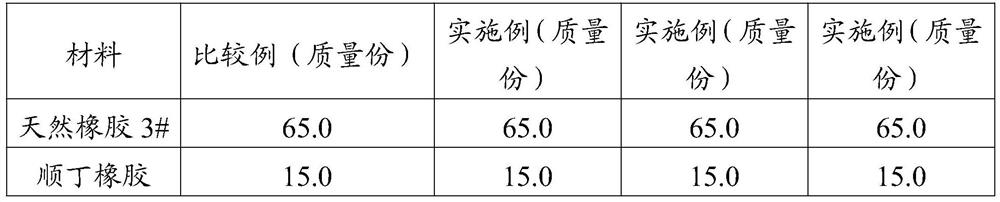

Embodiment 1

[0062] According to the formula in Table 1, add raw rubber such as natural rubber, carbon black, white carbon black, stearic acid, aromatic oil, anti-aging agent, and glass flakes into the Banbury mixer in sequence, and banbury at 130°C for 120 seconds , debinding at 160°C;

[0063] Put the obtained masterbatch, sulfur, accelerator, etc. into an internal mixer, mix at 105°C for 120 seconds, and then discharge to obtain a rubber composition.

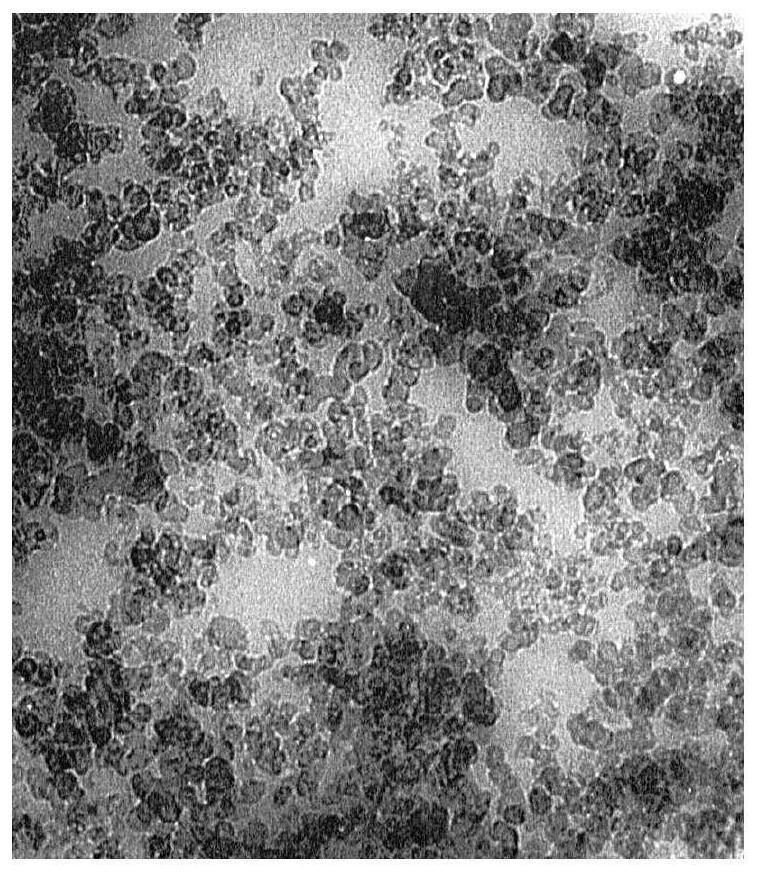

[0064] figure 1 It is the SEM figure of the same formula but not adding glass flakes in embodiment 1; figure 2 It is the dispersion state of embodiment 1 glass flakes in the sizing material. In the rubber composition of the present invention, glass flakes do not participate in chemical reactions, and can form nanoscale aggregates with soot and raw rubber microscopically. From a macroscopic point of view, they can be adsorbed on the surface of tires during tire use and can firmly hold ice and snow. road surface, and break the water film t

Embodiment 2-3

[0066] According to the formula in Table 1, according to the operation of Example 1, rubber materials were prepared respectively.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap