Hot rolled steel curled edge burr trimming and shoveling device

A hot-rolled steel coil and mechanical technology, which is applied in the field of hot-rolled steel, can solve problems such as hand scratches, low work efficiency, and burrs that cannot be shoveled, and achieve the effects of meeting user needs, improving work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

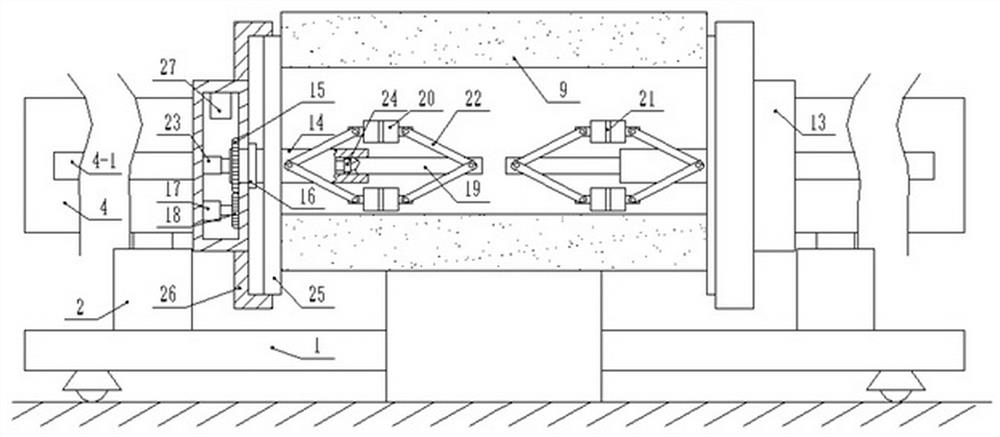

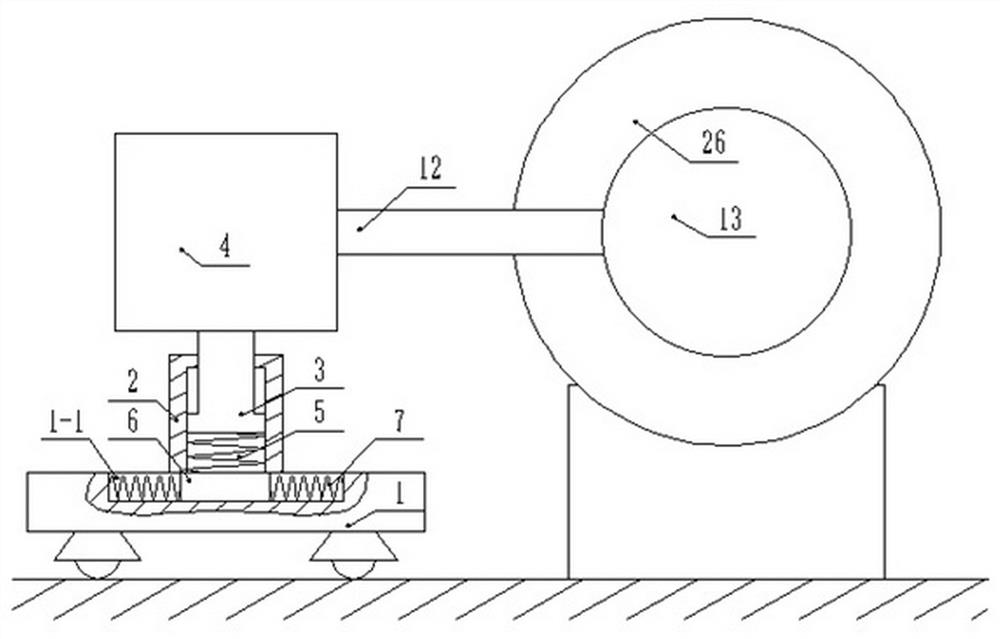

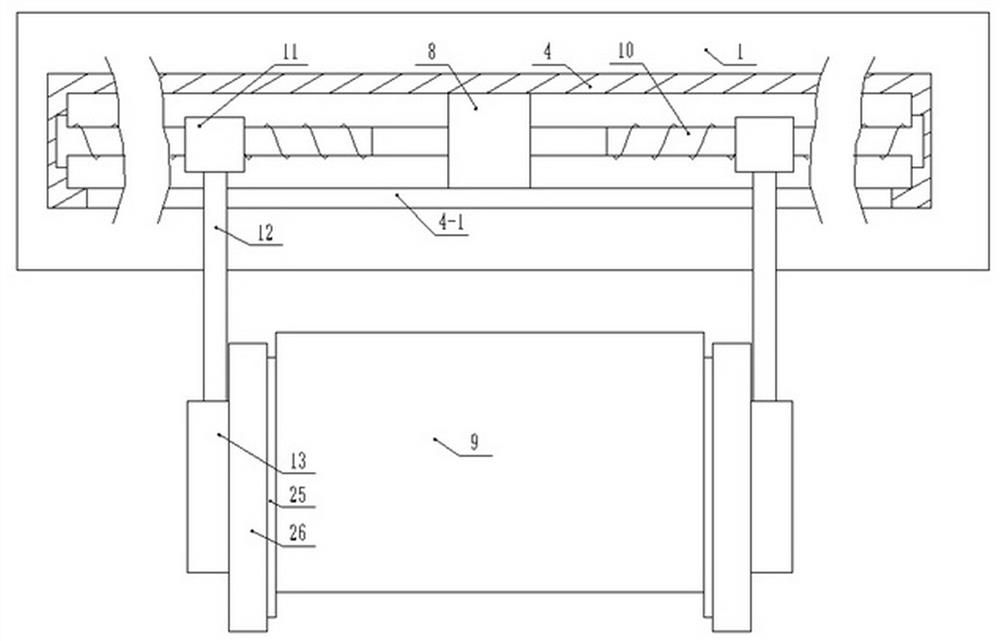

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a hot-rolled steel coil edge burr repairing device includes a mechanical trolley 1, the mechanical trolley 1 has its own power supply, and the top surface of the mechanical trolley 1 is fitted with a plurality of first barrels 2, so The first barrel body 2 is fitted and slidably provided with a T-shaped slide bar 3, the cross-section of the T-shaped slide bar 3 is square, and the top ends of a plurality of T-shaped slide bars 3 pass through the first barrel body 2 and are fixedly connected with the second barrel body 2. The barrel body 4, the T-shaped sliding rod 3 is slidingly connected with the first barrel body 2, the top surface of the mechanical trolley 1 is symmetrically opened with a plurality of dovetail grooves 1-1, and the dovetail grooves 1-1 fit and slide A first d

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap