Shock-proof and easily-replaceable horseshoe and manufacturing method thereof

A manufacturing method and technology for horseshoes, which can be applied to animal shoes, horseshoes, applications, etc., can solve the problems of affecting competition performance, high cost, horse racing injuries, etc., and achieve the effect of reducing frequency density and reducing the chance of injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

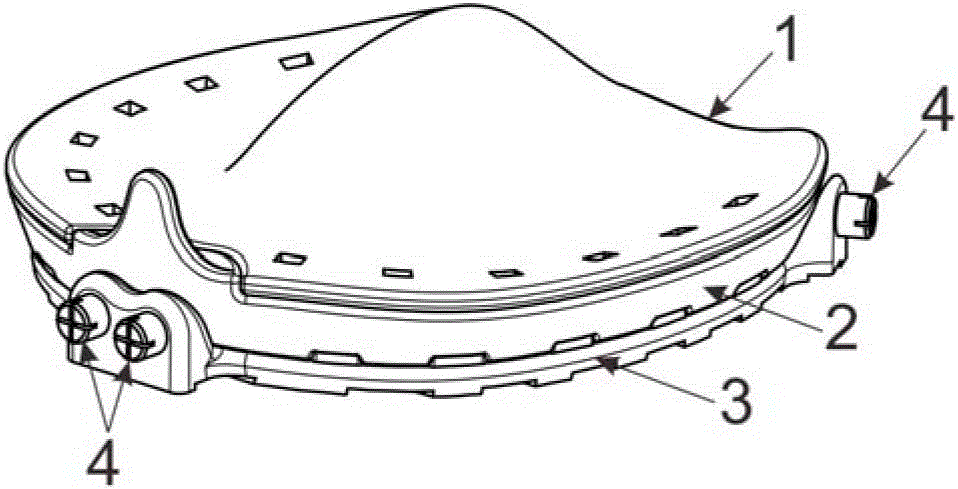

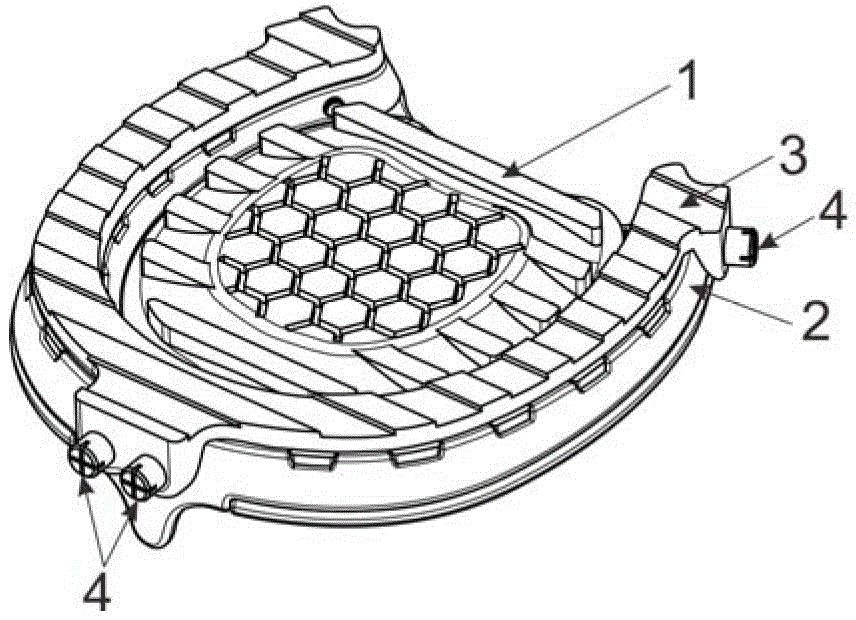

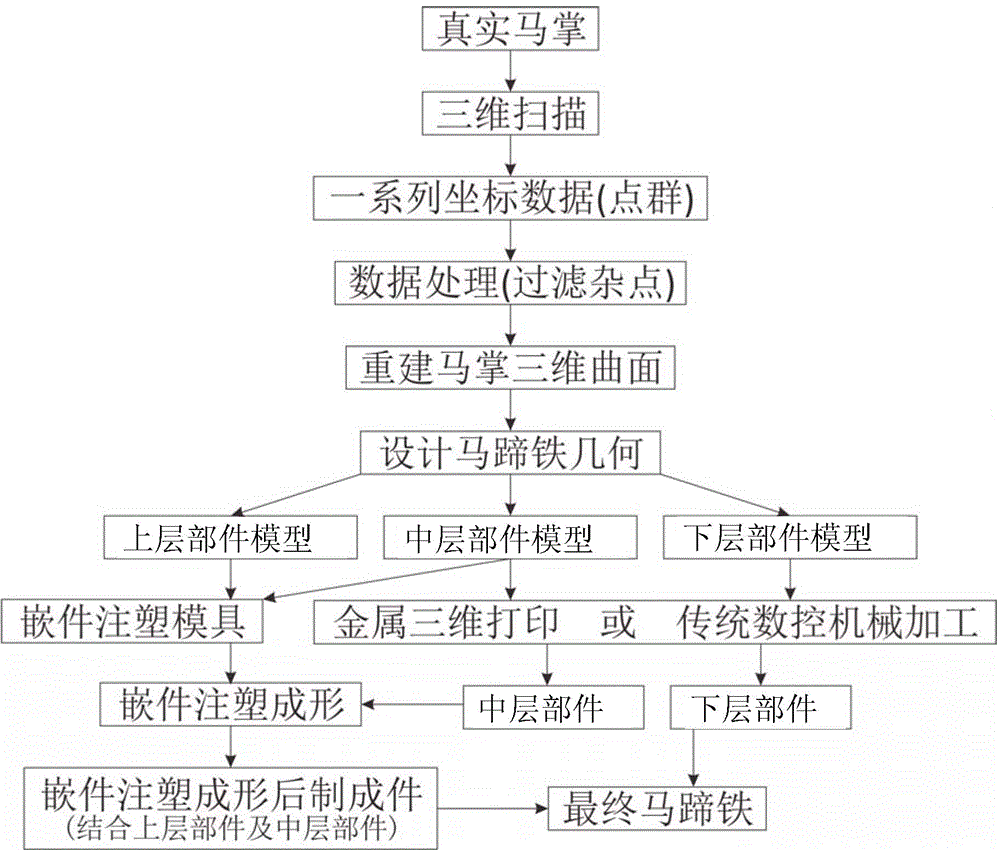

[0033] The present invention provides a shock-absorbing and easy-to-replace horseshoe, such as Figure 1 ~ Figure 3 As shown, it includes an upper layer component 1, a middle layer component 2, and a lower layer component 3 connected in sequence from the upper, middle, and lower layers. Wherein the upper part 1 is made of soft plastic, such as silicone rubber, polyvinyl chloride (PVC), polyurethane (PU), etc., and adopts a fully covered design to protect the bottom of the entire horseshoe from being crushed by small hard objects on the ground. The use of soft rubber can greatly reduce the impact force between the horseshoe and the ground and hard objects on the ground. And the shape

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap