Insulating PVC (polyvinyl chloride) glove and preparation method thereof

A technology for PVC resin powder and gloves, applied in the field of gloves, can solve problems such as the decline of insulation performance, and achieve the effects of low cost, strong market competitiveness and excellent insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

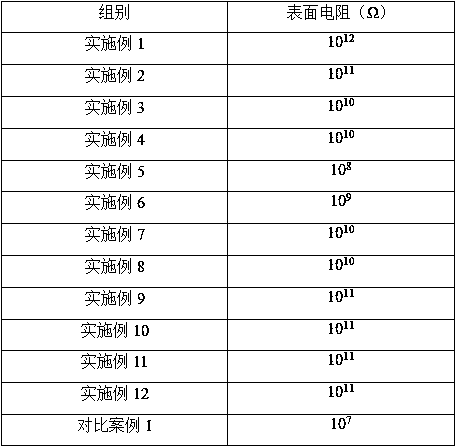

Examples

Embodiment 1

[0036] The raw materials are according to the following weight ratio:

[0037] Bulk polymerization PVC 100 parts;

[0038] 40 parts of trioctyl trimellitate;

[0039] 20 parts of tricresyl phosphate;

[0040] 10 parts of methyl pentachlorostearate;

[0041] 1.2 parts of stabilizer;

[0042] 30 parts of viscosity reducer;

[0043] Insulation improver (calcined clay: insulating mica = 1:1) 15 parts.

[0044] Add it into the mixing tank, stir for 5 hours, prepare PVC paste, and put it into the paste tank of the assembly line after vacuum defoaming.

[0045] Preheat the hand mold to 60°C, dip into the paste, drip for 1.5 minutes and then plasticize in an oven at 190±5°C. The plasticizing time is 5.5±0.5 minutes. After the hand mold is cooled to 70°C, impregnate the polyurethane slurry, and then dry the water in an oven at 130±10°C for 2 minutes. After cooling, crimping, demoulding, and finished product.

Embodiment 2

[0047] The raw materials are according to the following weight ratio:

[0048] Emulsion polymerization PVC 100 parts;

[0049] 40 parts of trioctyl trimellitate;

[0050] 20 parts of tricresyl phosphate;

[0051] 10 parts of methyl pentachlorostearate;

[0052] 1.2 parts of stabilizer;

[0053] 30 parts of viscosity reducer;

[0054] Insulation improver (calcined clay: insulating mica = 1:1) 15 parts.

[0055] Add it into the mixing tank, stir for 5 hours, prepare PVC paste, and put it into the paste tank of the assembly line after vacuum defoaming.

[0056] Preheat the hand mold to 60°C, dip into the paste, drip for 1.5 minutes and then plasticize in an oven at 190±5°C. The plasticizing time is 5.5±0.5 minutes. After the hand mold is cooled to 70°C, impregnate the polyurethane slurry, and then dry the water in an oven at 130±10°C for 2 minutes. After cooling, crimping, demoulding, and finished product.

Embodiment 3

[0058] The raw materials are according to the following weight ratio:

[0059] Bulk polymerization PVC 100 parts;

[0060] 40 parts of trioctyl trimellitate;

[0061] 20 parts of tricresyl phosphate;

[0062] 10 parts of methyl pentachlorostearate;

[0063] 1.2 parts of stabilizer;

[0064] 30 parts of viscosity reducer;

[0065] Insulation improver (calcined clay) 15 parts.

[0066] Add it into the mixing tank, stir for 5 hours, prepare PVC paste, and put it into the paste tank of the assembly line after vacuum defoaming.

[0067] Preheat the hand mold to 60°C, dip into the paste, drip for 1.5 minutes and then plasticize in an oven at 190±5°C. The plasticizing time is 5.5±0.5 minutes. After the hand mold is cooled to 70°C, impregnate the polyurethane slurry, and then dry the water in an oven at 130±10°C for 2 minutes. After cooling, crimping, demoulding, and finished product.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap