Aluminum alloy window mounting structure

An installation structure, aluminum alloy window technology, applied in the installation of window glass, parallel glass structure, window/door frame, etc., can solve the problem of inability to effectively prevent rainwater infiltration, material corrosion, etc., to prevent frame deformation and reduce damage. Corrosion, the effect of reducing the amount of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

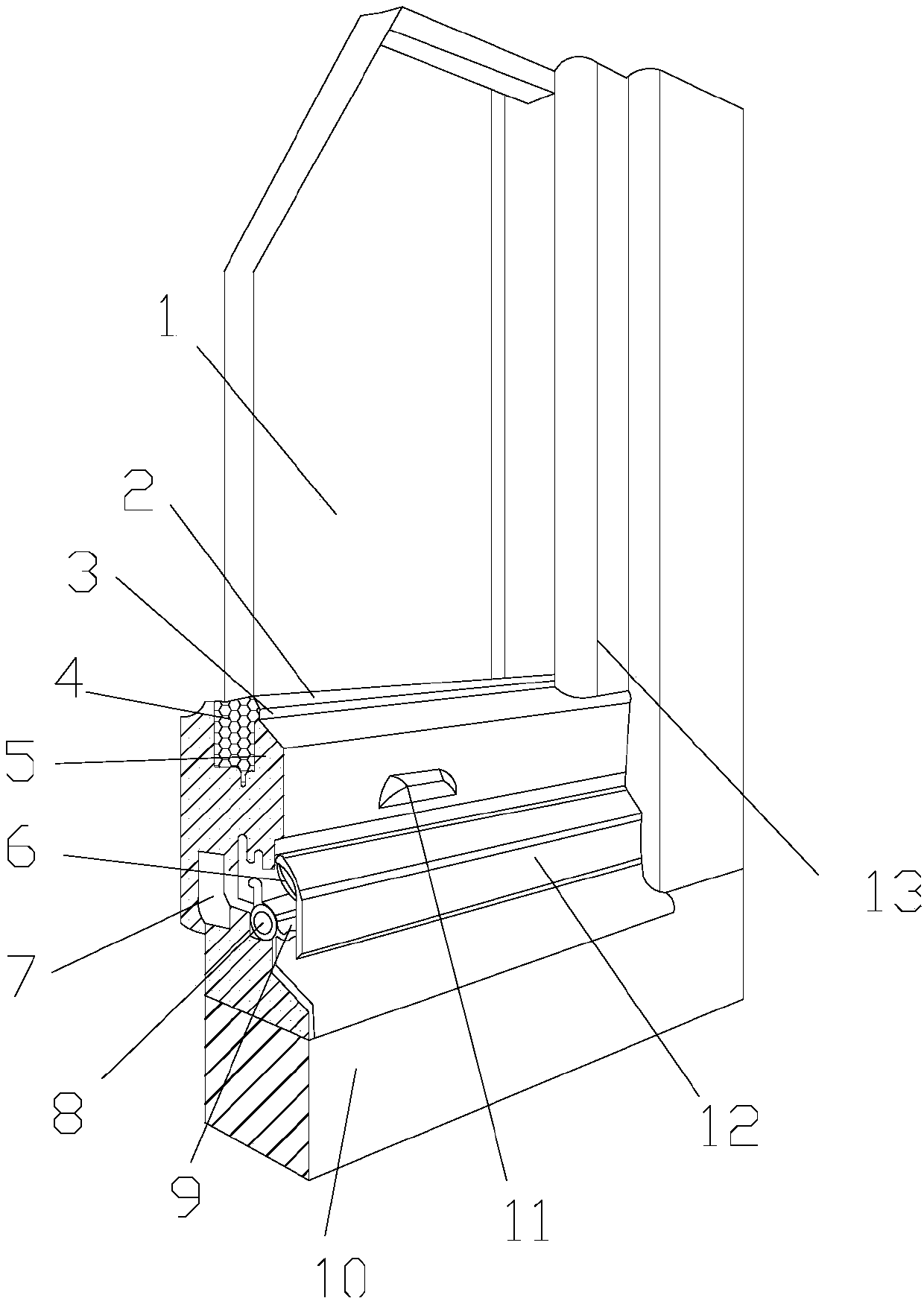

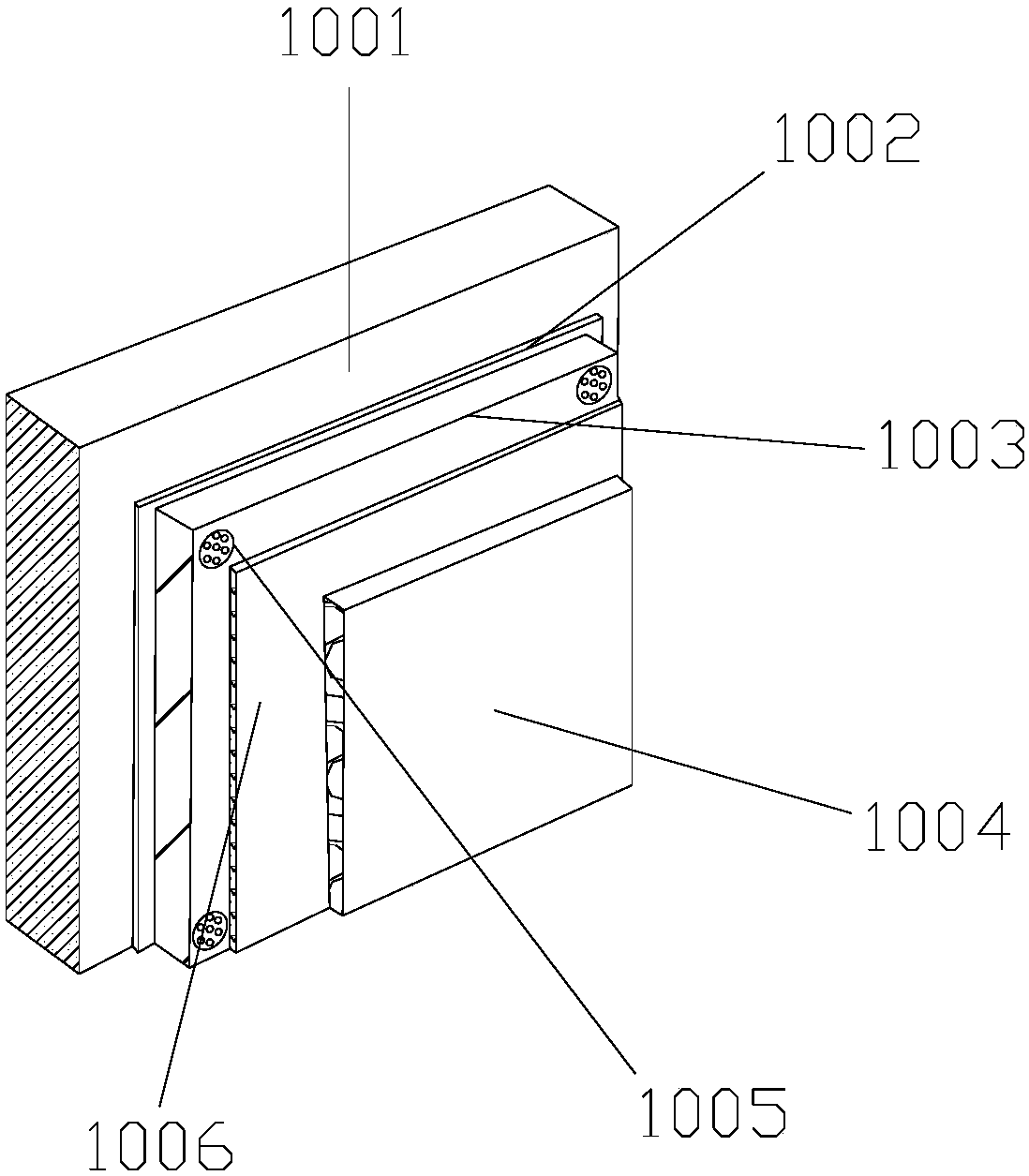

[0019] see figure 1 , figure 2 , the present invention provides a technical solution for the installation structure of aluminum alloy windows: the structure includes hollow glass 1, sealing silica gel 2, sealing gasket 3, glass groove 4, frame 5, waterproof sealing strip 6, drainage groove 7, slide rail shaft 8. Slide rail 9, window frame protection device 10, water outlet cover 11, protective cover 12, pressure plate 13, the hollow glass 1 is embedded and connected in the glass groove 4, and the upper end of the frame 5 is provided with a gasket 3, so The waterproof sealing strip 6 is embedded and connected in the protective cover 12, the slide rail shaft 8 and the slide rail 9 are an integrated structure, the lower end of the frame 5 is attached

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap