Method and equipment for crashing steel piece in large size

A steel, large-scale technology, applied in the field of crushing large-scale steel pieces, can solve the problems of polluting the surrounding environment, dangerous operation, high cost of crushing scrap steel blocks, and achieves the effect of low crushing cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

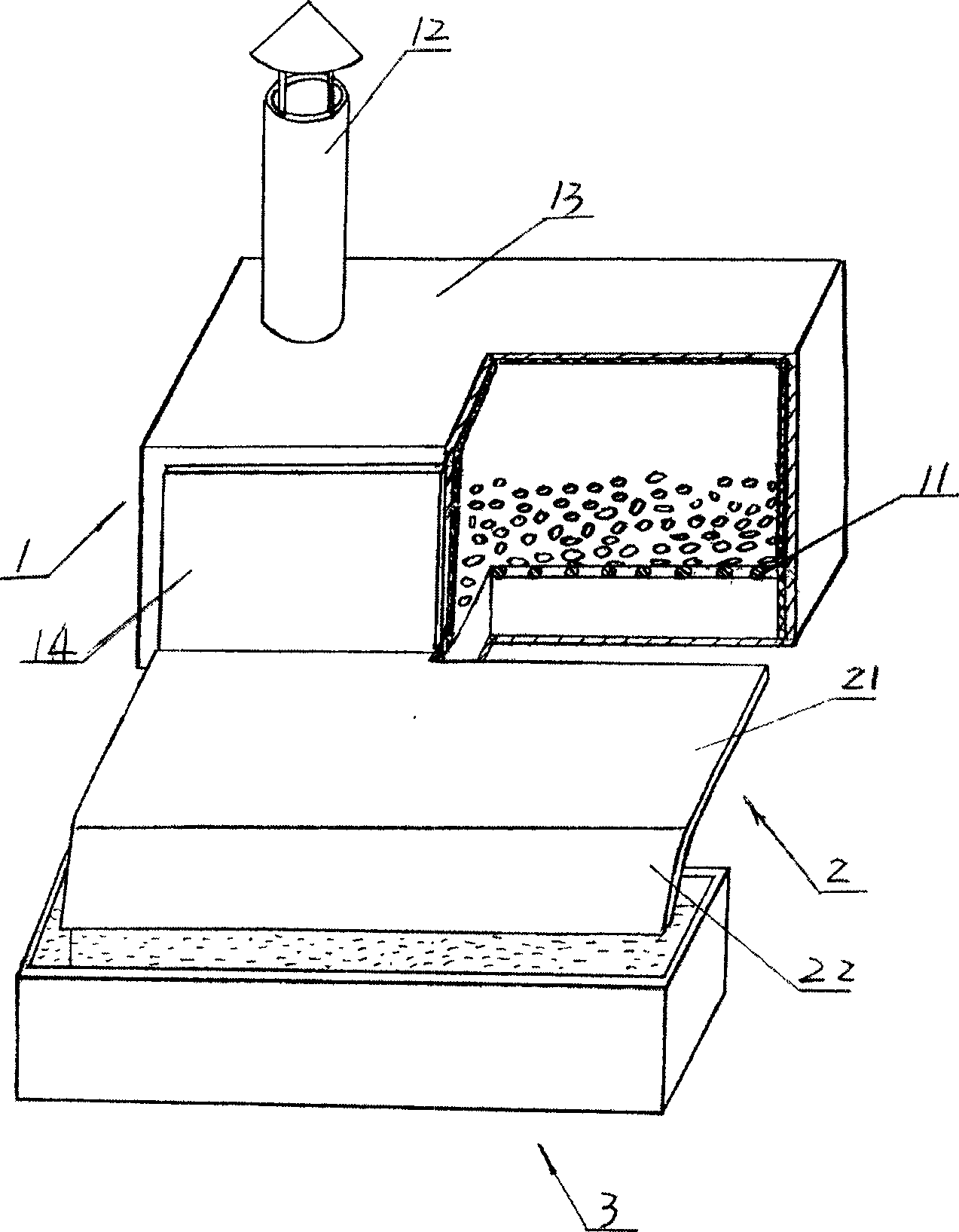

[0017] see figure 1 , the figure shows the appearance of an overall structure of an embodiment of the heating device for crushing large steel pieces proposed by the present invention. The device has a substantially rectangular combustion furnace 1 in appearance, and a wing fan 14 is arranged on the vertical surface along the longitudinal direction of the combustion furnace 1 . The upper part of the combustion furnace 1 is a closed surface 13 with a chimney 12, and a fire grate 11 is installed in its inner cavity and below the wing fan 14, and a blower is installed on one side of the bottom of the fire grate 11 (not given in the accompanying drawings) . In order to prevent the heat energy in the combustion furnace 1 from spreading outwards as much as possible, an insulating layer made of refractory material is provided on the inner periphery of the combustion furnace 1 and the inner side of the wing fan 14 .

[0018] The lower edge of the wing leaf 14 is equipped with a transver

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap