Tool deformation monitoring system for numerical control fixed beam type plano-boring and milling machine

A monitoring system and tool technology, used in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems that the tool cannot be well protected and cannot monitor the deformation of the tool, and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

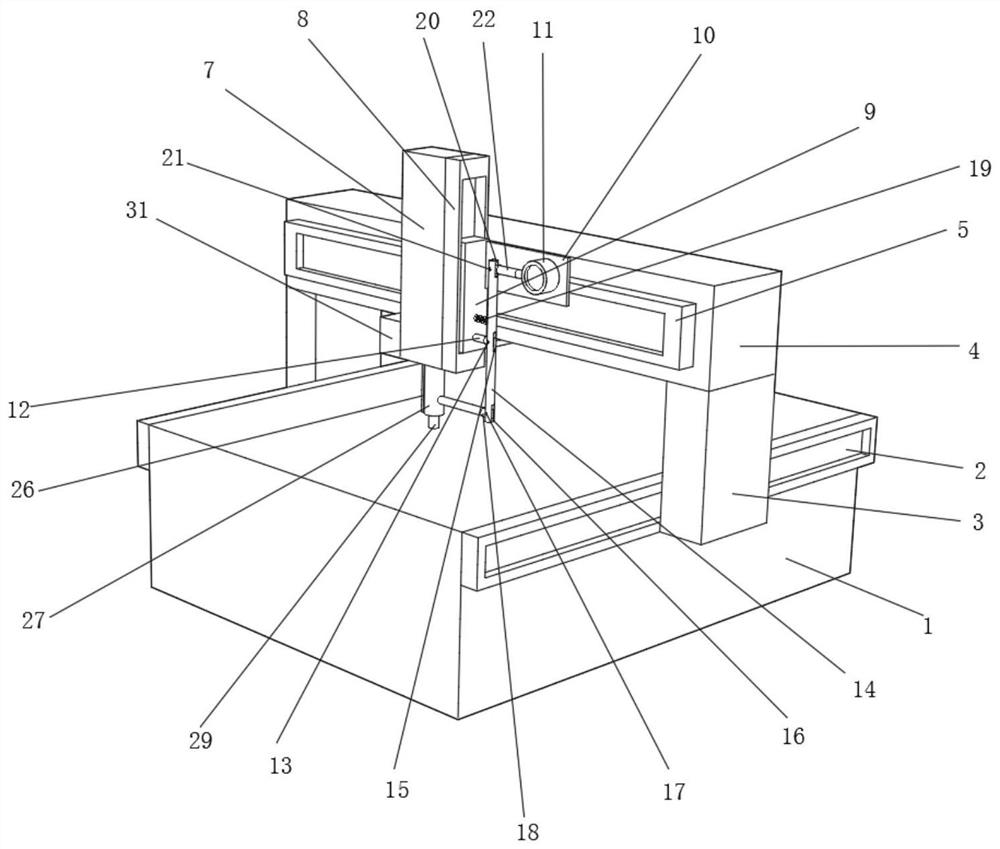

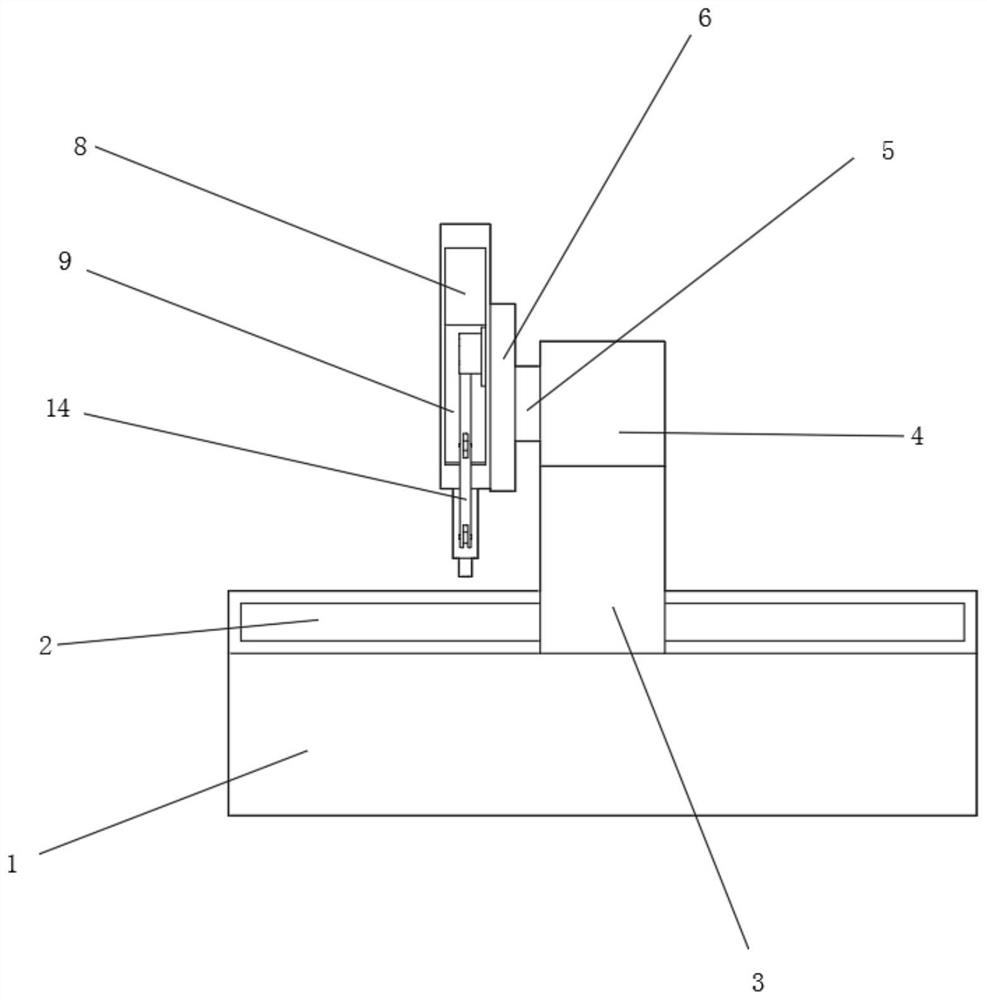

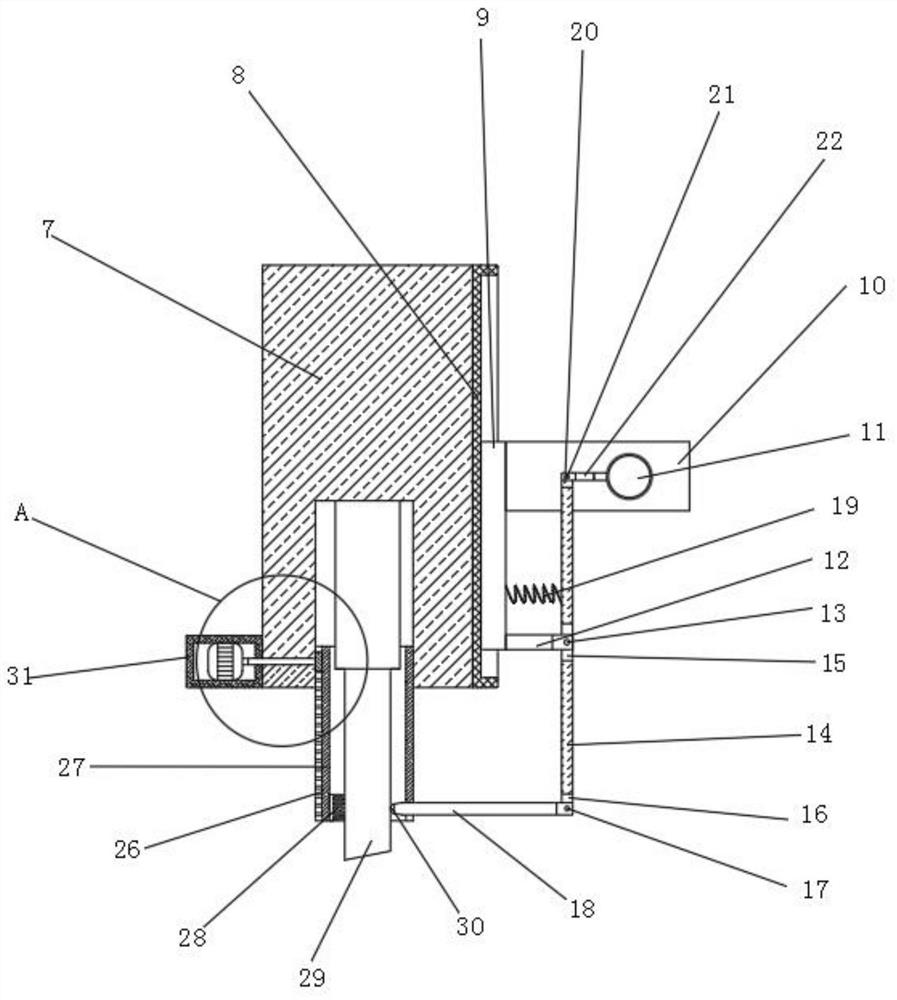

[0029] like Figure 1-6As shown, the embodiment of the present invention provides a tool-shaped modulation monitoring system for a number controlled beam type gantry boring and milling machine, including the beam 4, and the front side of the front side of the beam 4 fixedly connected to the drive shaft 5, Y to the drive block of the drive shaft 5. The front side fixedly connected to the Z-to the drive shaft 6, and the Z-to-the drive shaft 6 fixedly connected to the drive shaft 6, the tool mount 7, the right side of the tool mount 7 fixedly connected to the slide 8, the internal sliding connection of the chute 8 There is a slider 9, and the lower portion of the lower portion of the slider 9 is fixed to the finite bit rod 12, and the right end of the limit rod 12 is rotated through the first pin lever 13 in the first restricted groove 15 in the middle portion of the rotary rod 14, the rotor 14 The upper end of the upper end portion is rotated by the third pin lever 21, and the right end

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap