Digital controlled drilling machine capable of automatically adjusting depth of hole

An automatic adjustment, numerical control drilling machine technology, applied in automatic control device, digital control, boring/drilling and other directions, can solve the problem of difficult to meet the actual needs of the finishing field, unable to accurately monitor the drilling depth, unable to achieve unmanned monitoring, etc. problems, to achieve the effect of simple automatic adjustment and monitoring, high practical value, and intuitive display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

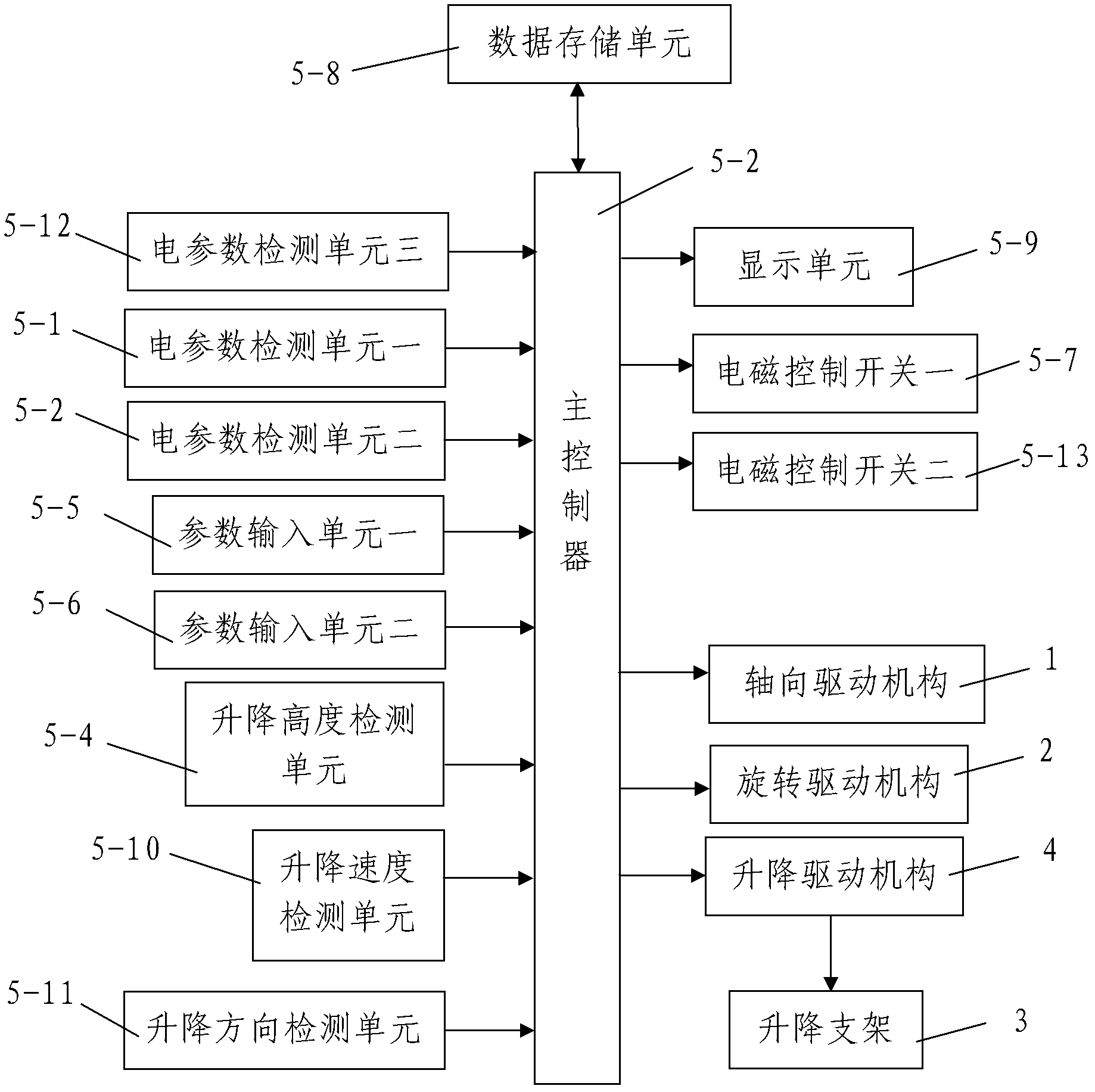

[0025] Such as figure 1 As shown, the present invention includes a drill body, an axial drive mechanism 1 for driving the drill bit to move axially, a workpiece clamping and fixing mechanism for clamping and fixing the workpiece to be processed, and a rotary drive mechanism for driving the drill bit to rotate 2 and the control system arranged on the body of the drilling machine, the axial driving mechanism 1 and the rotating driving mechanism 2 are both installed on the body of the drilling machine, and the two are respectively connected to the drill bit of the drilling machine through a transmission mechanism. The axial drive mechanism 1 and the rotary drive mechanism 2 are connected in transmission with the drill shaft on which the drill bit is installed through a transmission mechanism. At the same time, the present invention also includes a height-adjustable elevating bracket 3 installed on the drill press body, a horizontal bracket installed on the elevating bracket 3 and an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap