Electric discharge machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]An embodiment of the present invention will be described together with the drawings.

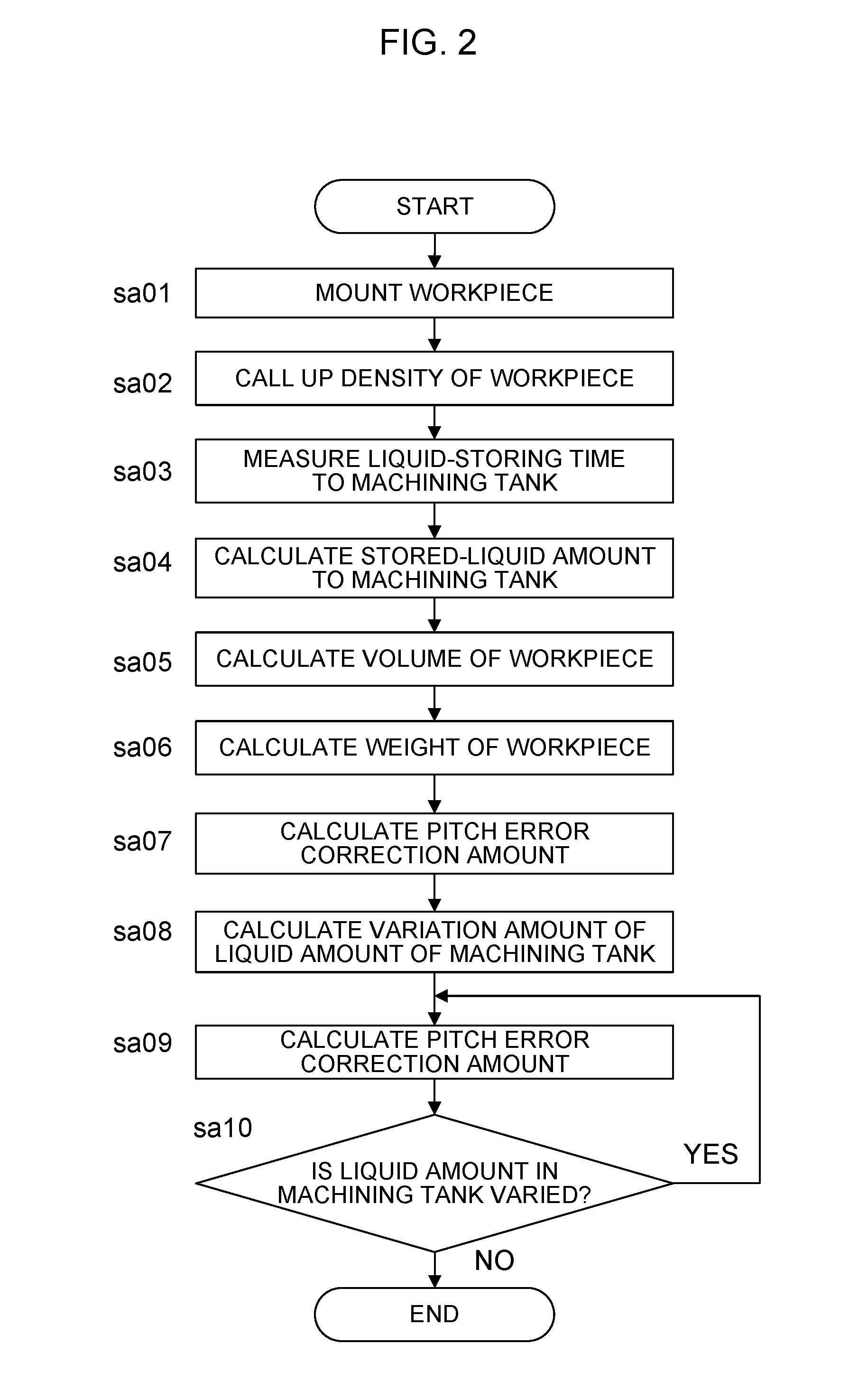

[0032]A wire electric discharge machine having a function to automatically calculate a weight of a workpiece to be machined according to the present invention will be described. More specifically, a weight W1 of a workpiece is automatically calculated by executing the following process.

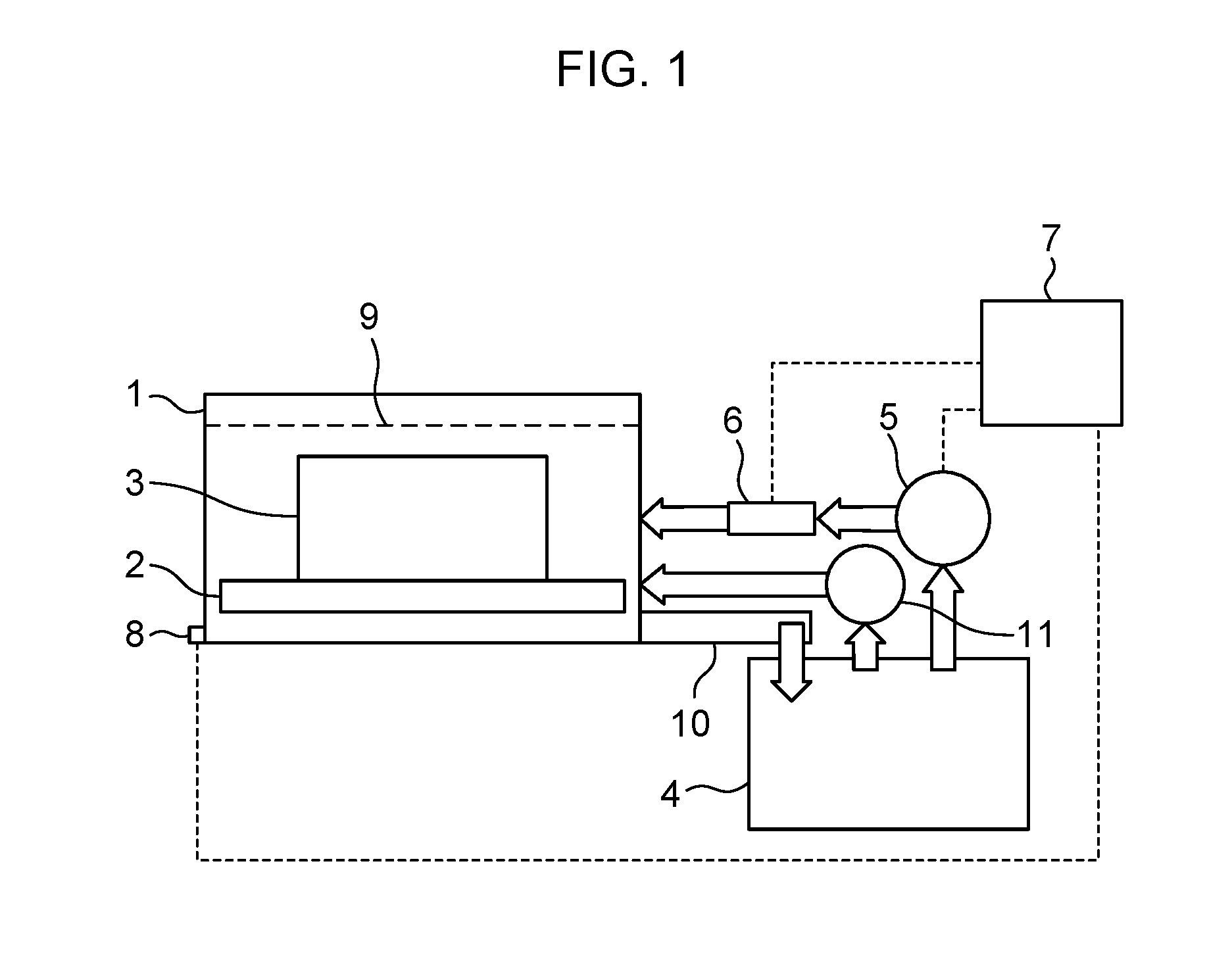

[0033]FIG. 1 is a schematic diagram of the electric discharge machine.

[0034]A liquid level h1 of a machining tank 1 is measured using a liquid level measuring section which measures a liquid level of the machining tank 1 when machining liquid is stored in the machining tank 1 from a liquid storage tank 4. More specifically, a liquid level (machining tank liquid level 9) stored in the machining tank 1 uses data acquired from a liquid level sensor 8 mounted in the machining tank 1. Instead of the liquid level sensor 8, there are also a method in which a height (=position of upper electrode support portion, position of

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap