Water-saving type intelligent control concrete prefabricated piece manufacturing device

A concrete prefabricated part, intelligent control technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve problems such as easy to spray too much, inconvenient to maintain concrete, inconvenient to apply mold evenly and quickly with demoulding oil, and save water resources , easy to maintain concrete, avoid the effect of excess water spilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

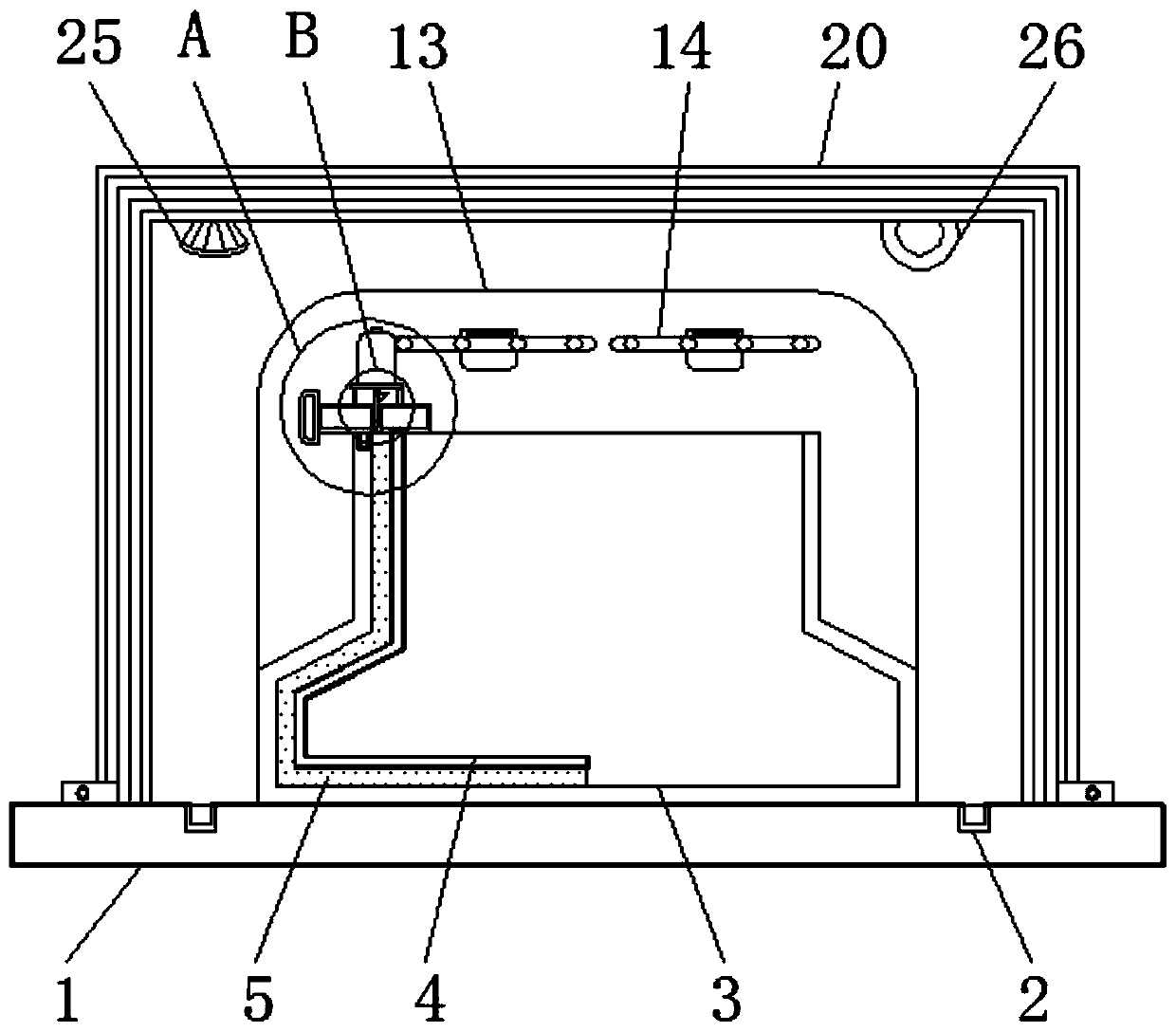

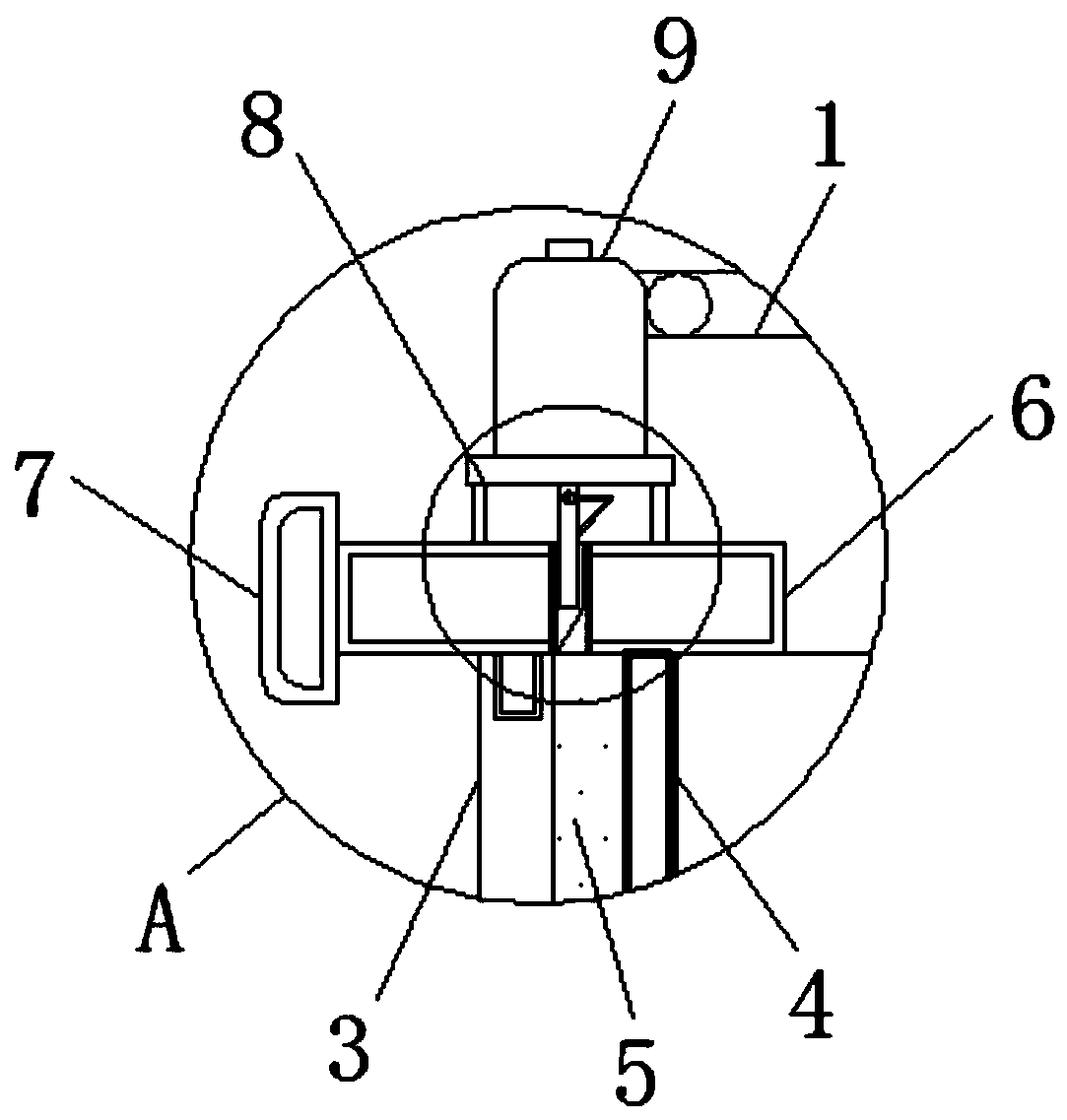

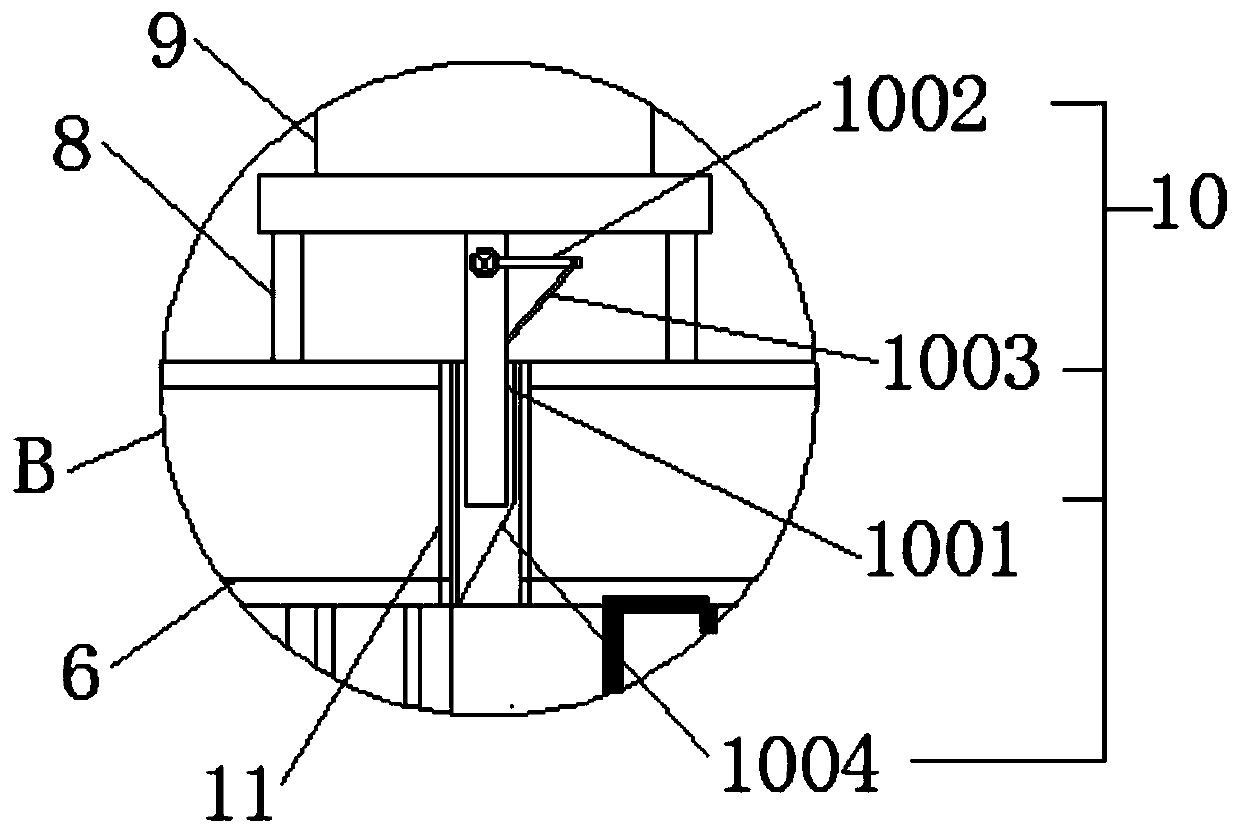

[0033] see Figure 1-8 , the present invention provides a technical solution: a water-saving intelligent control concrete precast manufacturing device, including a base 1, a positioning groove 2, a mold 3, a shell 4, a sponge board 5, a receiving box 6, a handle 7, a support Frame 8, demoulding oil barrel 9, oil outlet mechanism 10, limiting plate 11, air conditioner 12, water tank 13, water pump 14, dispersion pipe 15, branch pipe 16, atomizing nozzle 17, instal

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap