Filter element equipped with variably spaced reverse-washing filter

A backwashing and filter technology, applied in the field of filters, can solve the problems of decreased filtration efficiency, difficulty in sewage discharge, and increased pressure difference of filter elements, etc., and achieves the effects of convenient cleaning, improved cleaning efficiency, and increased clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

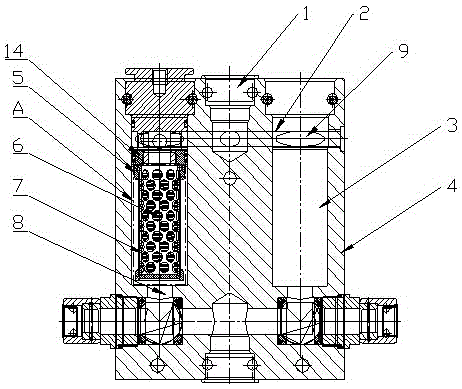

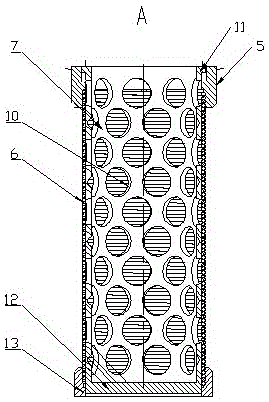

[0016] Such as figure 1 The schematic diagram shown shows that the filter element with a variable gap backwash filter of the present invention includes a valve body 4, a filter element housing 3 and a filter element assembly.

[0017] There are two cavities in the valve body 4 where the valve core housing 3 is installed, a liquid outlet 1 is provided at the middle of the upper end of the valve body 4, and a pair of symmetrical and cavities are provided at the lower end of the valve body 4 The connected liquid inlet 8 has a reverse discharge port connected to the liquid inlet 8 on the left and right sides of the liquid inlet 8 respectively.

[0018] There are two filter element housings 3, which are respectively installed in the two cavities of the valve body 4. There is a drain 9 at the upper end of the two filter element housings 3, and the drainage on the two filter element housings 3 The port 9 communicates with the liquid outlet 1 on the valve body 4 through a connecting pipe 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap